Screeding technology and screeding ruler for plaster work

A technology of punching bars and punching bars, applied in the direction of construction and building structure, can solve the problems of large error, no construction method, affecting the flatness of the wall surface, etc., to save time, improve quality, and reduce errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

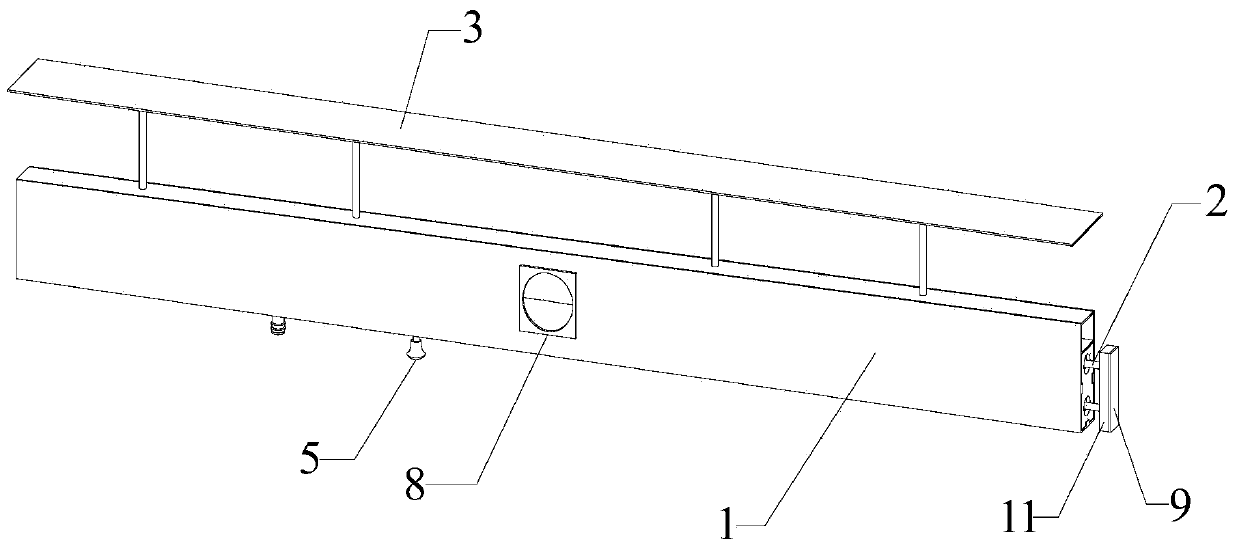

[0028] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

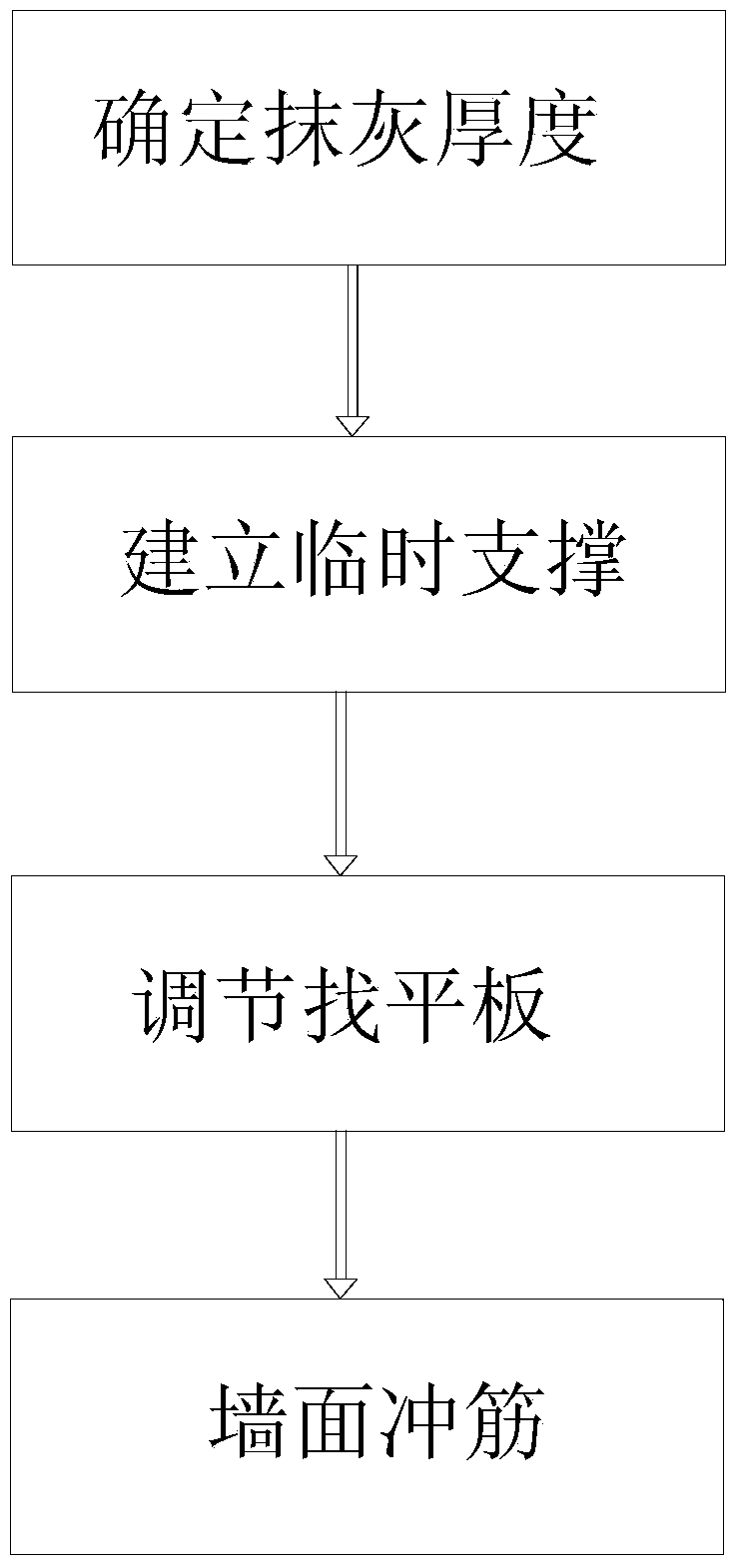

[0029] Such as Figure 1-6 Shown, a kind of punching process of plastering engineering, comprises the following steps:

[0030] Determining the thickness of the plaster: determine the thickness of the plaster on the wall 10 that has completed the base treatment and watering treatment, set up a marking line in front of the wall 10, and the distance between the marking line and the wall 10 is the thickness of the plastering;

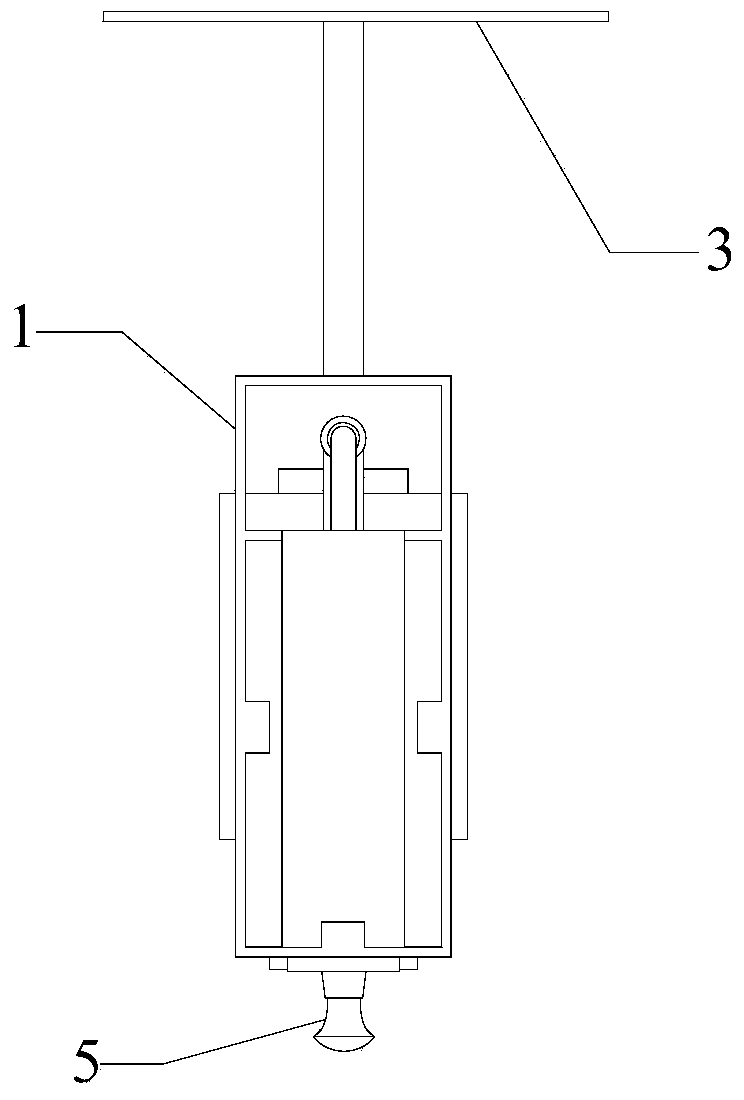

[0031] Establish temporary support: set up multiple temporary support devices on the side where the marking line is away from the wall 10, and the support devices are set vertically;

[0032] Adjust the screed plate 3: set the screed plate 3 between the support device and the marking line, connect the screed plate 3 with the support device, and adjust the position of the end surface of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com