Tunnel boring machine torque load simulation hydraulic system

A tunnel boring machine and torque load technology, which is applied in the direction of mechanical equipment, mechanical component testing, fluid pressure actuation devices, etc., can solve the problems of restricting the accuracy of construction data collection, difficult data collection, and inability to simulate dynamic torque loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

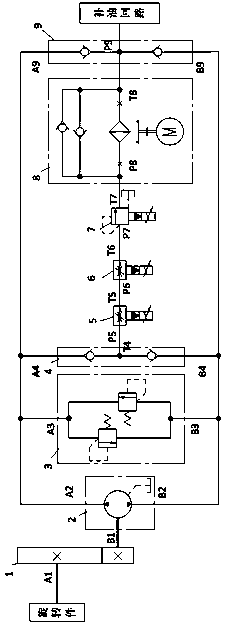

[0015] Such as figure 1 As shown, the present invention includes a rotating member, a speed increaser 1, a load simulation pump 2, a closed circuit safety valve group 3, an oil outlet check valve group 4, a slender hole electromagnetic proportional throttle valve 5, a thin edge electromagnetic proportional section Flow valve 6, electromagnetic proportional overflow valve 7, oil air cooling valve group 8, oil replenishment check valve group 9 and oil replenishment circuit; the rotating part is connected to the low-speed input end A1 of the speed increaser 1, and the high-speed speed increaser 1 The output terminal B1 drives the load simulation pump 2, a closed circuit composed of an oil port A2 of the bidirectional load simulation pump 2 and two relief valves installed in reverse parallel, an oil port A3 of the safety valve group 3, and two check valves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com