A kind of superconducting heat pipe and its heat transfer medium

A heat transfer medium and superconducting tube technology, which is applied in indirect heat exchangers, heat exchange materials, lighting and heating equipment, etc., can solve the problems of poor pressure resistance, easy corrosion of superconducting tubes, and low service life. The effect of stable heat transfer rate, good thermal conductivity and higher heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

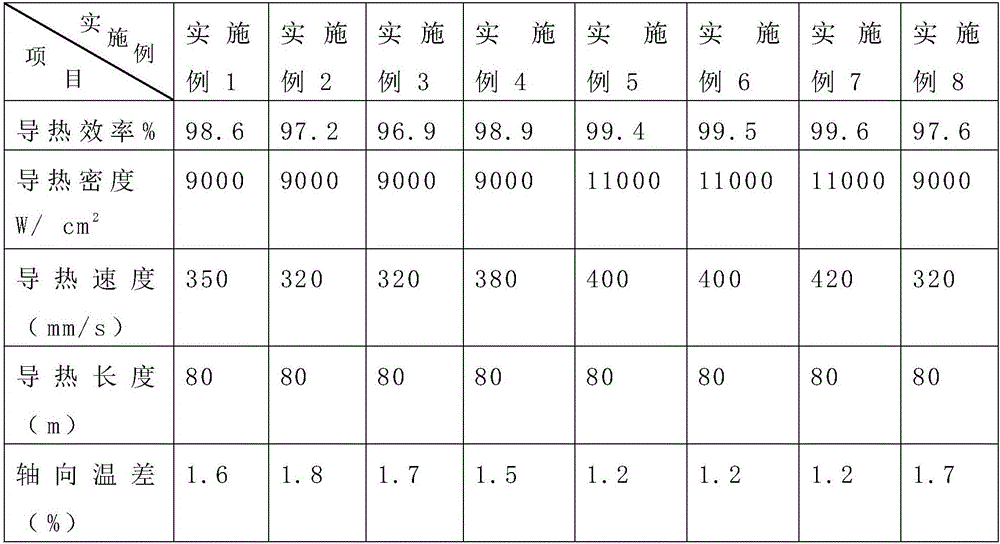

Examples

Embodiment 1

[0022] The superconducting heat pipe includes a vacuum heat pipe and a heat transfer medium, the heat transfer medium is located in the inner cavity of the vacuum heat transfer pipe; the heat transfer medium includes the following substances: 2 parts of zinc permanganate, 5 parts of magnesium chloride, and 10 parts of sodium tetraborate , 6 parts of potassium dichromate, 6 parts of ferrous chloride, 4 parts of strontium chloride, and 900 parts of water.

[0023] The volume of the heat transfer medium accounts for 0.8% of the inner cavity of the vacuum heat pipe.

Embodiment 2

[0025] The superconducting heat pipe includes a vacuum heat pipe and a heat transfer medium, the heat transfer medium is located in the inner cavity of the vacuum heat transfer pipe; the heat transfer medium includes the following substances: 1 part of zinc permanganate, 3 parts of magnesium chloride, and 5 parts of sodium tetraborate , 3 parts of potassium dichromate, 2 parts of ferrous chloride, 2 parts of strontium chloride, and 800 parts of water.

Embodiment 3

[0027] The superconducting heat pipe includes a vacuum heat pipe and a heat transfer medium, the heat transfer medium is located in the inner cavity of the vacuum heat transfer pipe; the heat transfer medium includes the following substances: 3 parts of zinc permanganate, 8 parts of magnesium chloride, and 15 parts of sodium tetraborate , 8 parts of potassium dichromate, 8 parts of ferrous chloride, 6 parts of strontium chloride, and 1000 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com