Optical lens vertical drive

A technology for optical lenses and drives, applied in optics, optical components, instruments, etc., can solve the problems of low precision of the vertical drives of optical lenses, friction, large contact area between hard alloy hemispheres and precision screws, etc., and achieve reduction The effect of return difference, small active area, high sensitivity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

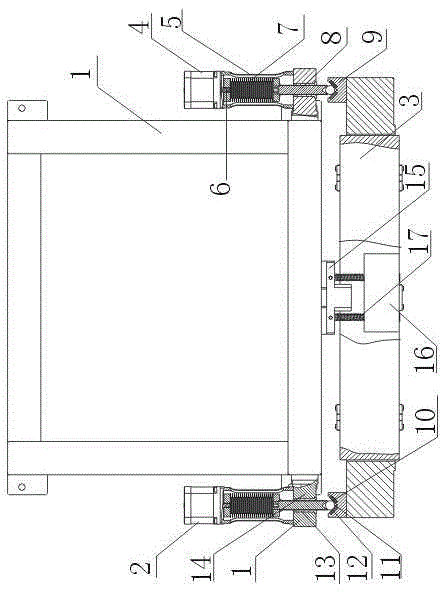

[0015] Such as figure 1 As shown, the optical lens vertical driver includes a support frame 1, an adjustment device 2 fixed on both sides of the support frame 1, and a mirror frame 3 fixed on the bottom of the support frame 1 through a universal ball head 15; the adjustment device 2 includes a step Motor 4, the casing 5 that is connected with stepper motor 4, described casing 5 is cavity structure, also comprises the telescopic coupling 7 that is arranged in casing 5 cavity structure and is connected with the output shaft 6 of stepper motor 4 and The precision screw 8 connected to the other end of the telescopic coupling 7 also includes positioning seats 9 located on the upper surfaces of both ends of the frame 3, and the ends of the precision screw 8 fall on the positioning seats 9; wherein the positioning seats 9 are V-shaped The positioning seat, the end of the precision screw 8 has a V-shaped groove 10, and also includes a hard alloy sphere 11, and the hard alloy sphere 11...

Embodiment 2

[0018] In this embodiment, on the basis of Embodiment 1, the telescopic coupling 7 is a bellows coupling.

[0019] In this embodiment, the use of the welded bellows coupling can greatly reduce the backstroke difference generated during the adjustment process of the vertical drive of the optical lens and keep the backstroke difference stable.

Embodiment 3

[0021] On the basis of Embodiment 1 or Embodiment 2, this embodiment also includes a screw sleeve 13 fixed on the precision screw rod 8, and a connecting block 14 connected to the screw sleeve 13, and the end of the shell 5 is fixed on the connecting block. The upper end of 14, connecting piece 14 is welded on the side wall of support frame 1.

[0022] In this embodiment, the screw sleeve 13 covering the precision screw 8 protects the precision screw 8 so that the precision screw 8 is not easy to be worn. The connecting block 14 is welded on the side wall of the support frame 1, which ensures that the precision screw rod 8 will not fall off from the support frame 1 due to the vibration of the stepping motor 4 when it moves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com