Precision electric adjustment frame

A kind of electric adjustment frame, precise technology, applied in the machine/bracket, installation, optics and other directions, can solve the problems of the precision electric adjustment frame is not high, the return difference is large, etc., to achieve high accuracy, reduce the effect of return difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

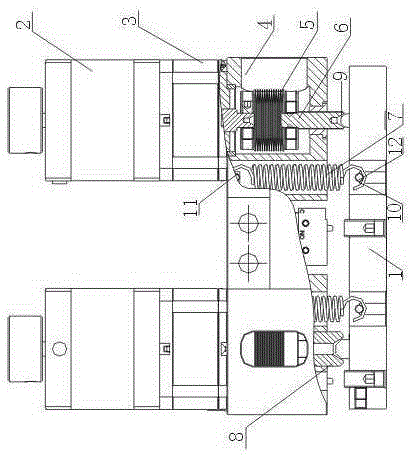

[0014] Such as figure 1 As shown, the precision electric adjustment frame includes a mirror frame 1, a connecting block 4, and driving components fixed on both sides of the connecting block 4. The driving components include a stepping motor 2 and a miniature planetary gear reducer 3 connected to the stepping motor 2. , wherein the connection block 4 is a cavity structure, and also includes an elastic coupling 5 arranged in the cavity structure of the connection block 4 and connected to the output shaft of the miniature planetary gear reducer 3, and also includes an output of the elastic coupling 5 The end of the precision screw 6 connected to each other, the end of the precision screw 6 falls on the upper surface of the picture frame 1, and also includes a spring 7 connected to the connection block 4 at one end and connected to the picture frame 1 at the other end; the end of the precision screw 6 has a conical groove A8 , also includes a cemented carbide half-steel ball 9 fix...

Embodiment 2

[0017] The elastic coupling 5 is a welded bellows elastic coupling.

[0018] In this embodiment, the precision electric adjustment frame adopts the welded bellows coupling, which can greatly reduce the backstroke difference generated during the adjustment process of the precision electric adjustment frame and maintain the stability of the backstroke difference.

Embodiment 3

[0020] In this embodiment, on the basis of embodiment 1 or embodiment 2, the spring 7 is an extension spring, the inner wall of the connecting block 4 is fixed with a screw A11, the upper hook of the extension spring is covered on the screw A11, and the Bottom has hole 10, and the sidewall of hole 10 is fixed with screw B12, and the lower hook of extension spring is enclosed within on the screw B12.

[0021] In this embodiment, one end of the extension spring is fixed on the connecting block 4, and the other end is fixed in the frame 1. When the frame 1 moves down or up under the action of the precision screw 6, the extension spring will stretch or shrink , when the motor stops moving, the active force generated by the extension spring will adjust the mirror frame 1 to return to the original position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com