Method for identifying dust and pocking marks on surface of big-caliber optical element

An optical element, a large-diameter technology, applied in the field of pattern recognition, can solve the problems of no automatic identification of pits and dust, difficult to distinguish, etc., to achieve high classification accuracy and avoid complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

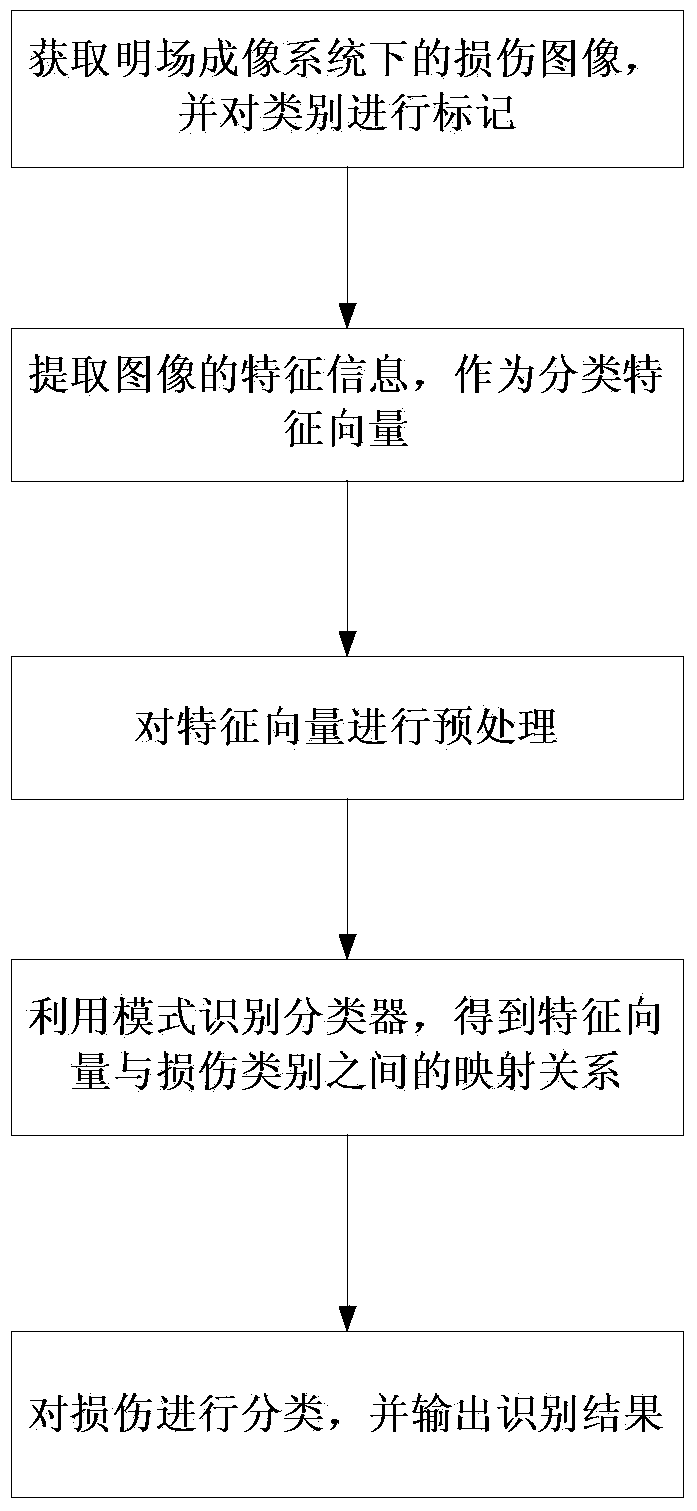

[0025] figure 1 It is a flow chart of the method for identifying dust and pitting on the surface of a large-diameter optical element of the present invention, as figure 1 As shown, the method for identifying dust and pitting on the surface of the large-diameter optical element includes the following steps:

[0026] Step 1: Use an image acquisition device to collect surface damage images of large-aperture optical components under bright field conditions as sample images, and mark the damage category corresponding to each sample image;

[0027] In an embodiment of the present invention, the image acquisition device includes a microscope lens and an area array CCD camera, and examples of bright field images of dust and pits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com