Ceramic oven

An oven, ceramic technology, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problems of easy deformation, affect the appearance of the oven, damage to the oven, etc., to ensure the appearance and aesthetics. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

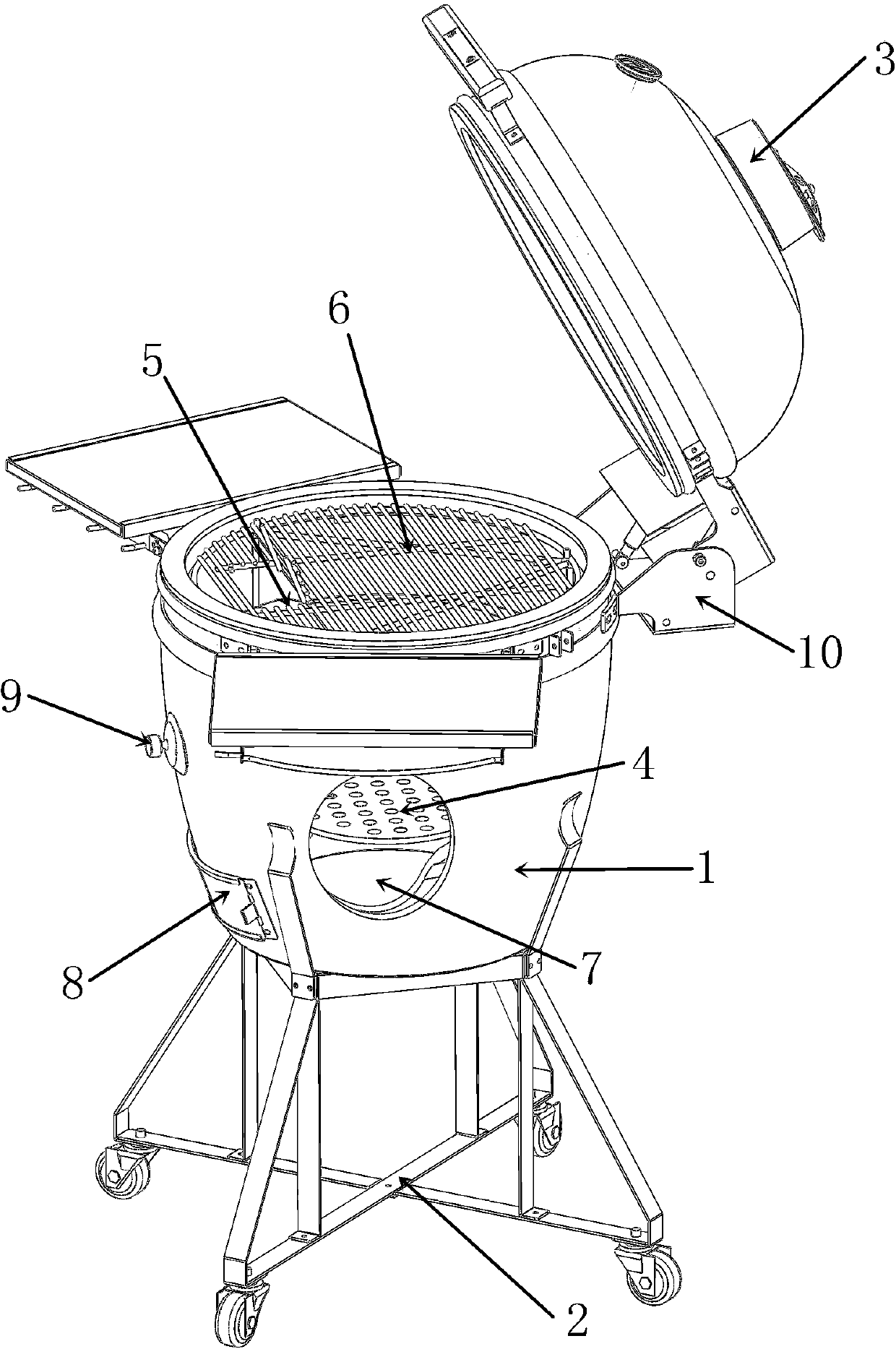

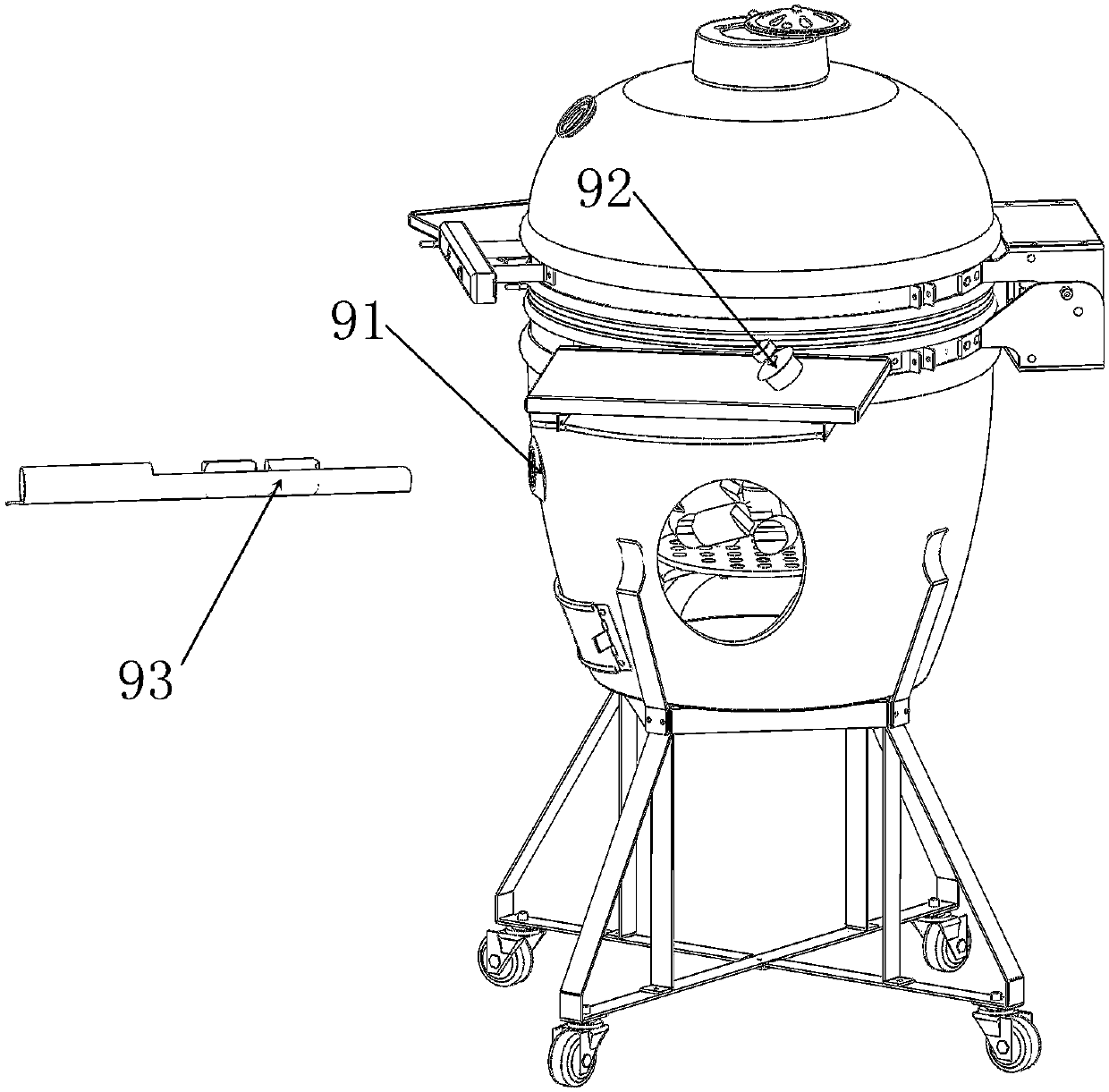

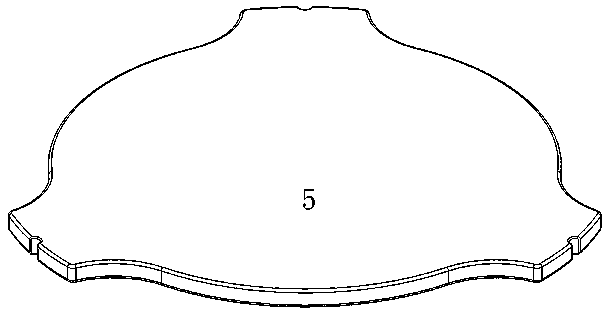

[0043] Such as figure 1 As shown, the ceramic oven of the present invention comprises a furnace body 1, a support arranged at the lower end of the furnace body and a furnace roof 3 arranged on the furnace body, wherein the support is a flat steel trolley 2, which includes a furnace body support 21 and is fixedly connected to the The lower support 22 at the lower end of the furnace shaft support is formed by vertically arranged flat steel. The lower support 22 is provided with casters. The casters use four universal wheels 23, two of which have brakes. , two without brakes, which ensures that the furnace can be very stable both at rest and in motion. see Figure 13 shown. A reflector 7, a charcoal pad 4, a deflector 5, and a grilling net 7 are sequentially arranged in the furnace body 1 from bottom to top, and an air inlet is arranged on the furnace body 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com