Slag removing device of aluminum ingot continuous casting production line slag removing robot

A casting production line and robot technology, applied in casting equipment, manufacturing tools, mechanical cleaning, etc., can solve the problems of high temperature danger, long replacement time, etc., and achieve the effects of avoiding the danger of disassembly, reducing the number of replacements, and shortening the time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the present invention will be described in detail below in conjunction with the accompanying drawings.

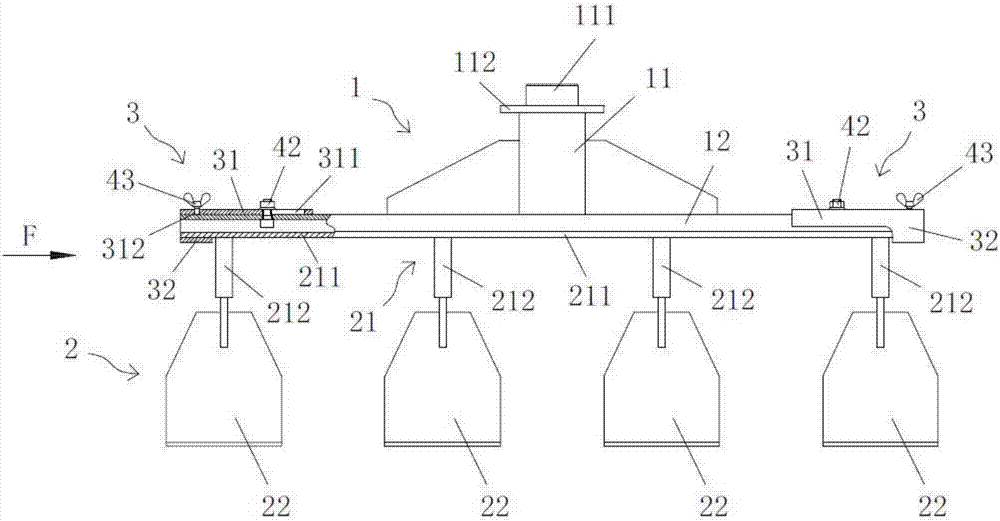

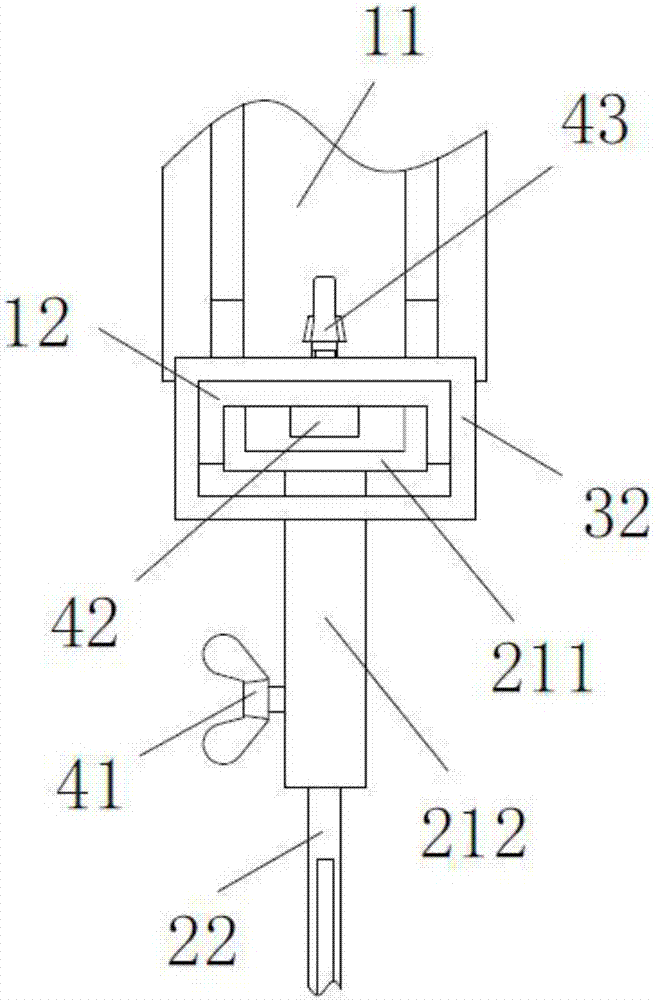

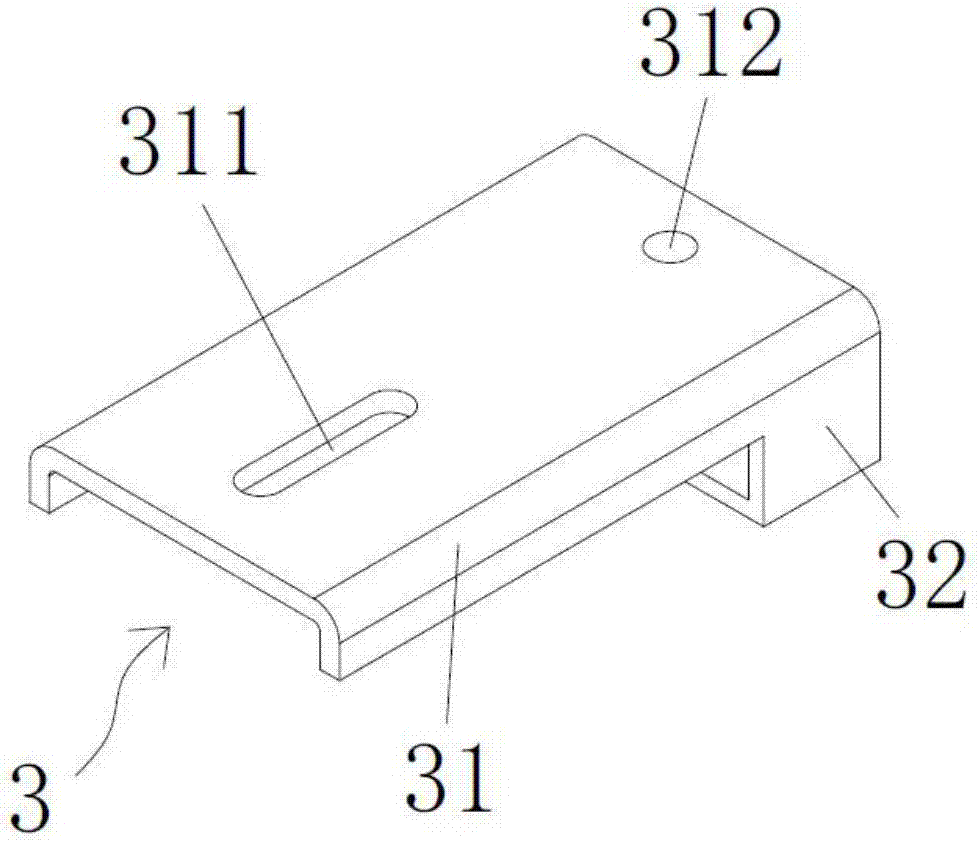

[0019] Such as figure 1 and figure 2 As shown, the slag removal device of the slag removal robot in the aluminum ingot continuous casting production line of the present invention includes a fixed frame 1 , a slag shovel assembly 2 and a quick-change fixture 3 . Wherein, the quick-change clamps 3 are located at both ends of the fixed frame 1 , and can reciprocate and slide horizontally relative to the fixed frame 1 , so as to realize the connection and disassembly between the slag shovel assembly 2 and the fixed frame 1 .

[0020] The fixed frame 1 is a T-shaped structure, including a vertical frame 11 and a horizontal frame 12 perpendicular to each other. Wherein, the upper end of the vertical frame 11 is connected with the mounting flange of the slag removal robot, and the lower end is fixedly connected with the middle position of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com