Nondestrutive detection method of microregion residual stress

A residual stress, non-destructive testing technology, applied in special data processing applications, material analysis using radiation diffraction, instruments, etc., can solve the problem of long time, reduce measurement time, reduce time consumption, and facilitate the promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific implementation mode 1: In this implementation mode, an XRD equipped with a small X-ray point source and a two-dimensional plane X-ray detector is utilized. 2 Equipment, adjust the X-ray spot diameter (30 μm ~ 10mm) and the measurement area, according to the equipment to determine the X-ray tube voltage and tube current are 30 ~ 60kV and 35 ~ 45mA. The purpose is to realize the fast residual stress detection in the tiny area.

[0011] This embodiment is directed to crystalline bulk materials. First, adjust the XRD 2 The optical path and collimation system of the equipment meet the hardware requirements for determining residual stress. The second step is to install the sample required to determine the residual stress on the equipment sample test bench. The sample 1 is placed horizontally, and the XRD 2 The X-ray plane detector 2 on the equipment is arranged at an acute angle with the horizontal plane towards the direction of the sample to be measured, and the ...

specific Embodiment approach 2

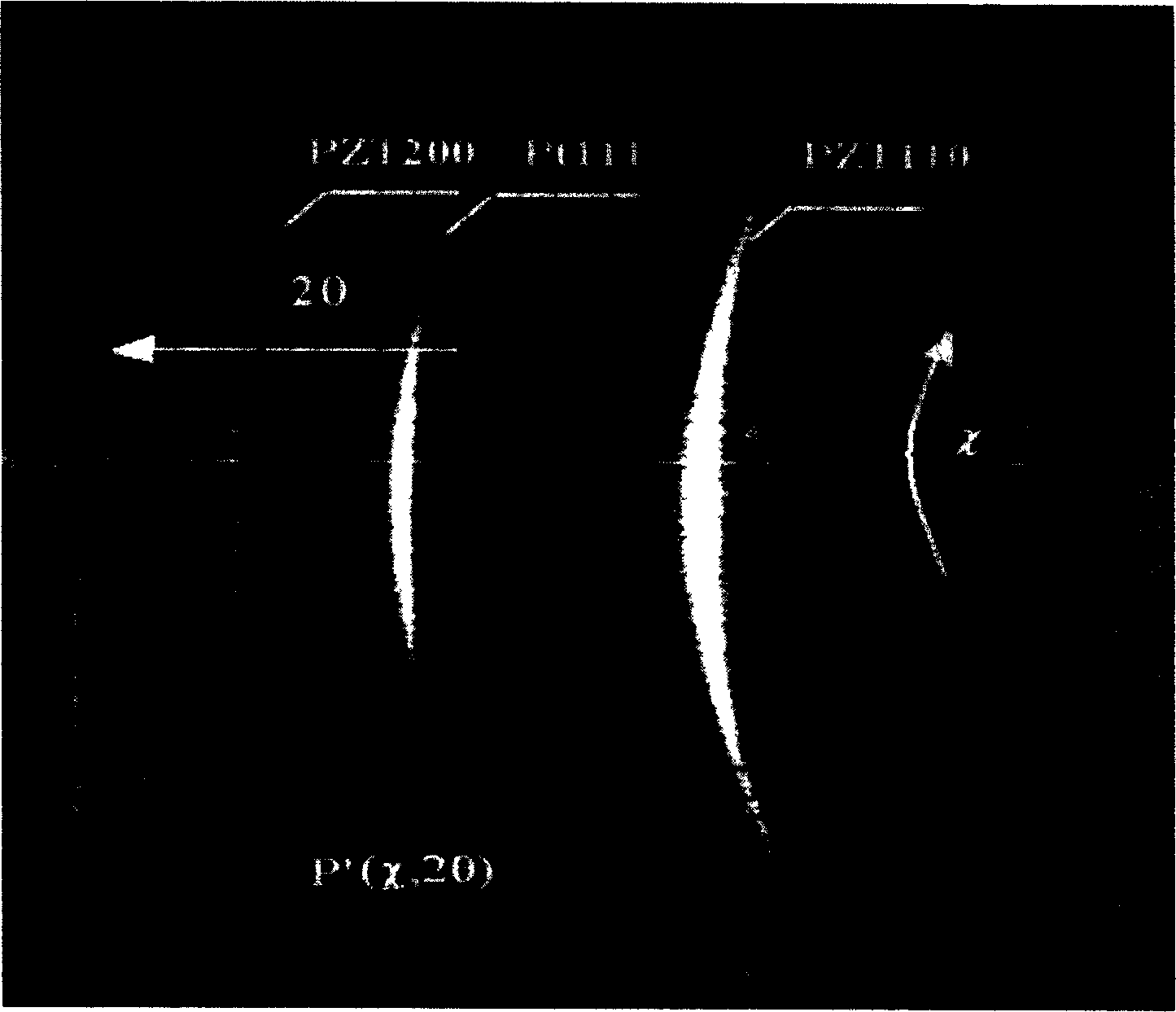

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the Pb(Zr 52 Ti 48 )O 3 The film was tested, and the film crystallized into a perovskite phase at 650°C. During the measurement, the incident angle ω was selected as 18°, the X-ray spot diameter was adjusted to 100 μm, the X-ray tube voltage and tube current were 40 kV and 40 mA, respectively, and the scanning time was 1 minute.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the detection is performed on crystalline ZnO or TiN or Au thin film materials, and the measurement method is the same as Embodiment 1.

[0014] Principle of the present invention is as follows:

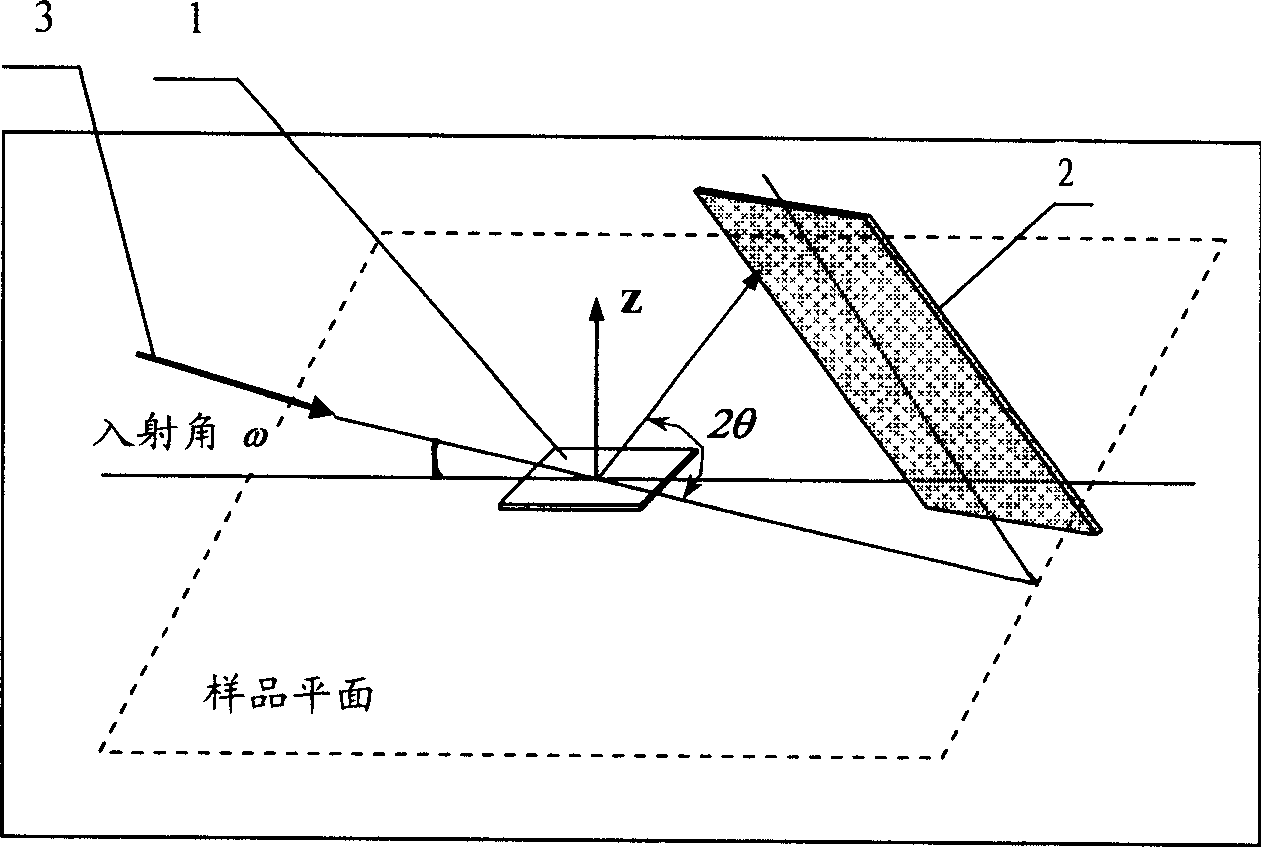

[0015] The XRD adopted in the non-destructive testing method of residual stress in the present invention 2 The schematic diagram of the optical path of the device is shown in figure 1 As shown, the two-dimensional planar X-ray detector forms an acute angle with the horizontal direction to receive the scattered signal from the sample. The test sample is placed horizontally, the X-ray incident angle is ω, and the spot position and diameter of the X-ray can be adjusted (30μm~ 10mm), to measure the residual stress of different tiny areas on the surface of the sample.

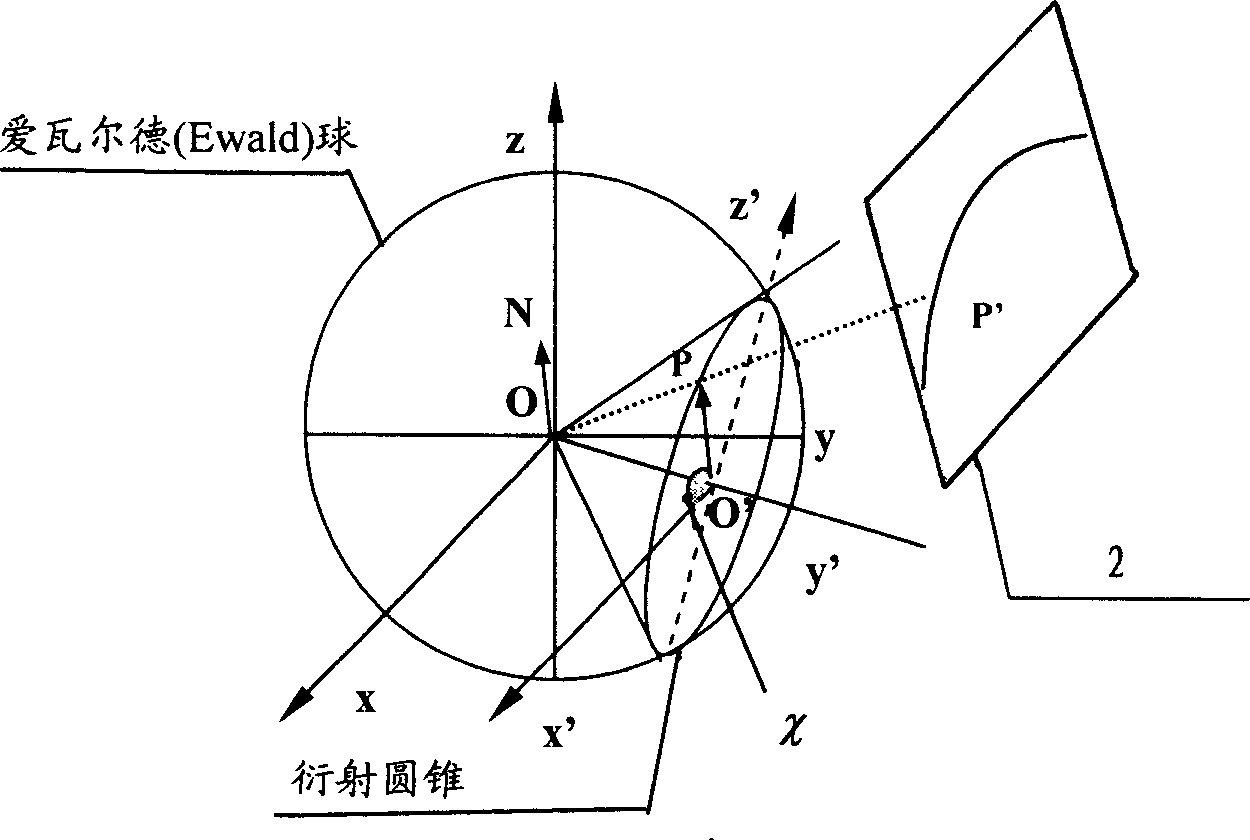

[0016] figure 2 for XRD 2 Schematic diagram of the principle of two-dimensional surface detection diffraction. For...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com