Flow characteristic testing platform of oil injector of motorcycle

A technology of flow characteristics and fuel injectors, which is applied in the field of testing equipment for motorcycle engine fuel supply systems, can solve the problems of poor testing accuracy of motorcycle fuel injectors and the inability of users to obtain data, etc., and achieve simple structure and reliable working performance , Control the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

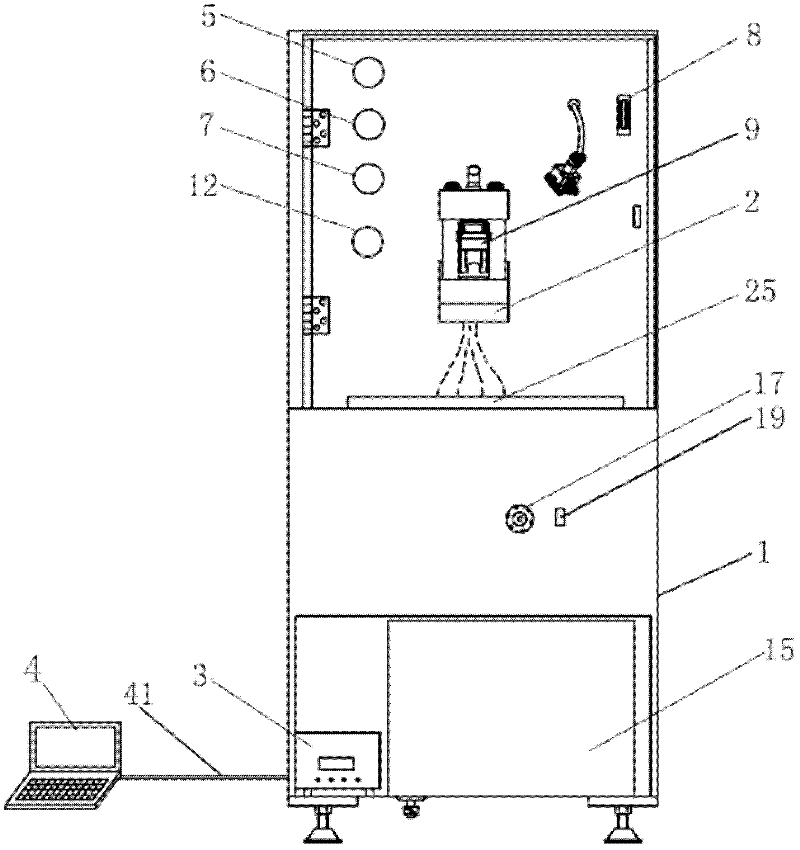

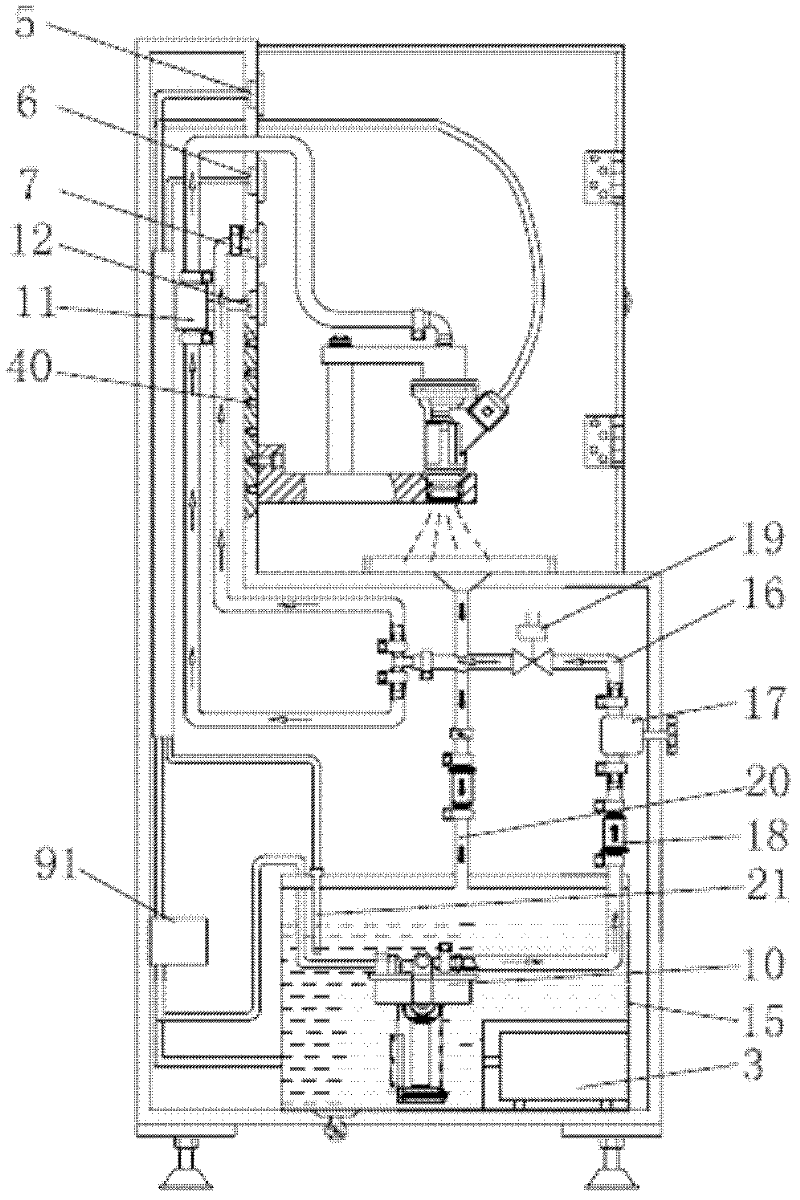

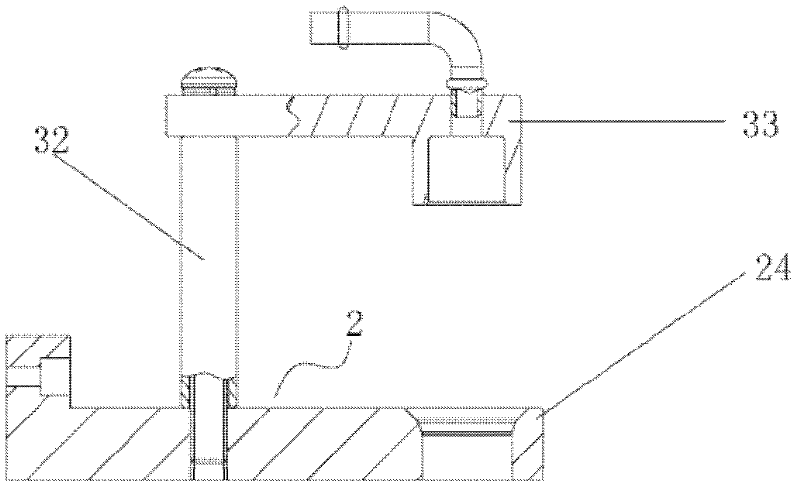

[0026] See Figure 1 ~ Figure 3 , A motorcycle fuel injector flow characteristic test bench, including a test bench main body, a control host 4, a fuel supply system, and a detection display system. The test bench main body includes a cabinet 1 and an injector installed in the cabinet 1 Fixing fixture 2. The detection and display system includes a voltmeter 5, an oil temperature gauge 6, an oil pressure gauge 7 and a thermometer 8 installed on the main body of the test bench. The control host 4 is connected to the fuel injection system via the first communication line 41. The injector controller 91 of the injector 9 on the fixed fixture 2 is connected, and the detection display system and the injector 9 are connected with the fuel supply system. The test bench also includes the control host 4 for testing the injector. 9 dynamic flow rate, static flow rate and invalid injection time test system, the control host 4 commands the injector 9 fuel injection control parameters includi...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is that: the motorcycle fuel injector flow characteristics test bench eliminates the flow display meter and the flow meter 11 on the basis of the embodiment 1, while adding a measuring bottle 13 and a precision electronic scale 14 Therefore, the detection system in this embodiment includes a measuring bottle 13 used to collect the oil ejected from the fuel injector 9 and a precision electronic scale 14 used to measure the weight of the measuring bottle 13. The precision electronic scale 14 is connected to the second communication line 141 The control host 4 is connected. In this embodiment, the precision electronic balance has a weighing accuracy of 0.001 g and a measurement time accuracy of 1 ms.

[0041] Based on the detection system of this embodiment, the quantitative test method of the motorcycle injector flow characteristics test bench of the present invention is as follows:

[0042] Measurement of static injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com