Heat-resistant efficient heat-exchanging seamless steel pipe

A seamless steel pipe, high-efficiency technology, applied in pipes, rigid pipes, pipeline heating/cooling, etc., can solve the problems of low heat dissipation efficiency of the exhaust tube, thermal expansion and deformation of the exhaust pipe, limited heat transfer efficiency, etc., and achieve simple structure, The effect of avoiding thermal deformation, high service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention will not be limited.

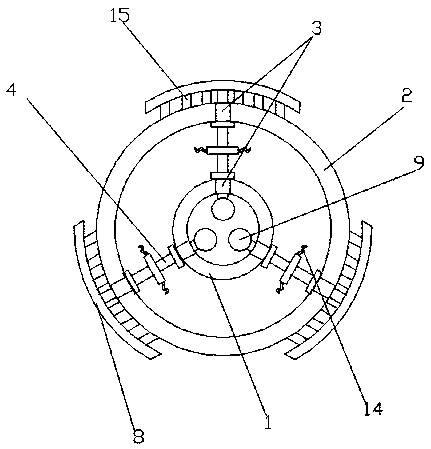

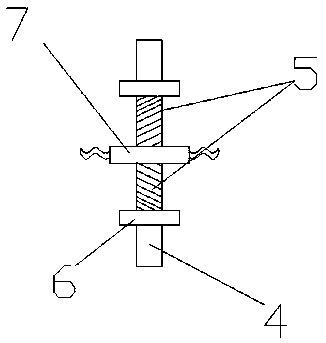

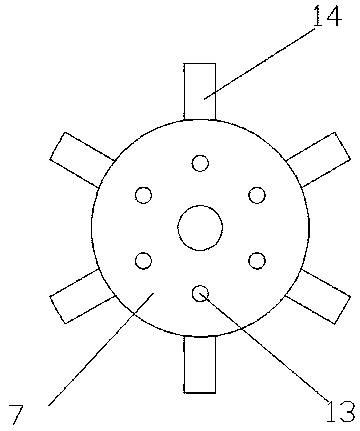

[0015] Such as Figure 1 to Figure 4 As shown, a heat-resistant high-efficiency heat-exchanging seamless steel pipe includes an inner tube 1 and an outer tube 2 arranged coaxially, and the inner tube 1 and the outer tube 2 are provided with an annular array of heat-exchanging holes 3. A heat exchange column 4 is fitted in the heat hole 3, and the two ends of the heat exchange column 4 are respectively arranged inside the inner tube 1 and outside the outer tube 2, and the outer surface of the heat exchange column 4 is provided with external threads extending from the middle to both ends. part 5, the external thread part 5 is screwed with a locking circular plate 6 and a heat sink 7, the upper end of the heat exchange column 4 is connected with a heat dissipation plate 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com