Drilling rig with mechanical positioning device

A mechanical positioning and drilling rig technology, applied in automatic control devices, metal processing mechanical parts, boring/drilling, etc., can solve the problems of inconvenient access, heavy block gauge, etc., to improve service life, good cooling effect, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the drawings and specific embodiments.

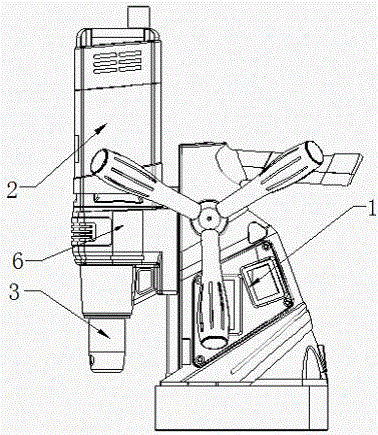

[0038] See attached picture. The drilling rig provided in this embodiment includes a fixed body 1 and a machine head 2 that is perpendicular to the bottom of the machine body to move relatively back and forth, and a spindle 3 for installing tools is provided on the machine head.

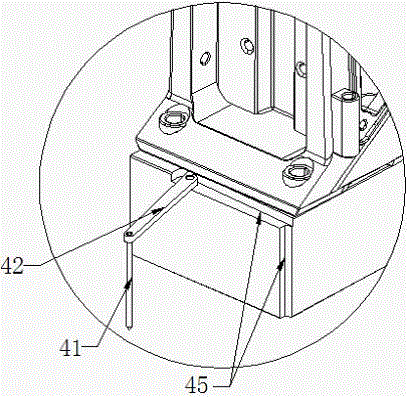

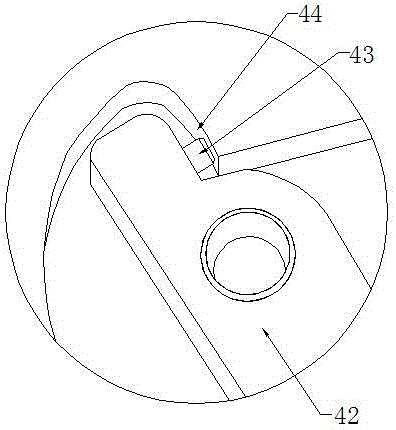

[0039] In order to accomplish the positioning operation conveniently and quickly during the drilling process, the drilling rig of this embodiment is equipped with a mechanical positioning device with a movement limit position. The mechanical positioning device includes a positioning pin 41, and the mechanical positioning device moves to the limit position. At this time, the longitudinal center line of the positioning pin 41 is on the same straight line with the spindle axis.

[0040] In the first embodiment, the mechanical positioning device further includes a support rod 42, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com