Drilling machine with optical positioning device

A technology of optical positioning and drilling rigs, which is applied in the direction of automatic control devices, boring/drilling, large fixed members, etc., can solve the problems of inconvenient access, heavy weight of block gauges, etc., to improve service life, improve processing efficiency, cooling better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

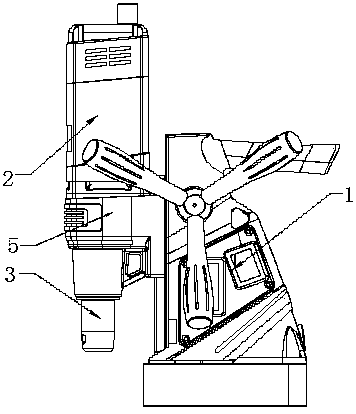

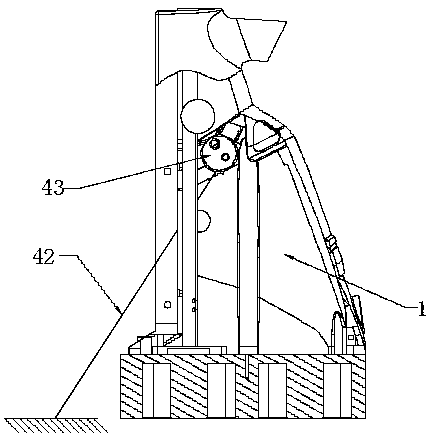

[0032] See attached picture. The drilling rig provided in this embodiment includes a fixed fuselage 1 and a machine head 2 that moves back and forth relative to the bottom of the fuselage. The machine head is provided with a main shaft 3 for installing a cutter.

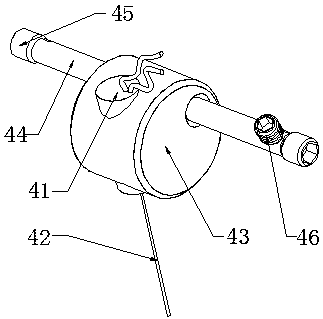

[0033]In the embodiment of the present invention, an optical positioning device is provided on the fuselage 1, and the optical positioning device includes an optical positioning lamp 41, a lamp holder 43 and a shaft 44. In order to enable the optical positioning device to realize the positioning function, the optical positioning lamp 41 emits The intersection point of the light beam 42 and the bottom plane of the fuselage is on the axis of the main shaft 3 . The optical positioning lamp 41 is fixedly installed on the lamp holder 43, and the lamp holder 43 is fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com