Small-aperture square copper pipe tearing device and method

A small-diameter, copper tube technology, used in pipe shearing devices, shearing machine equipment, shearing devices, etc., can solve the problems of finger scratches, waste, reduce the effective length of copper tubes, and reduce the risk of injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

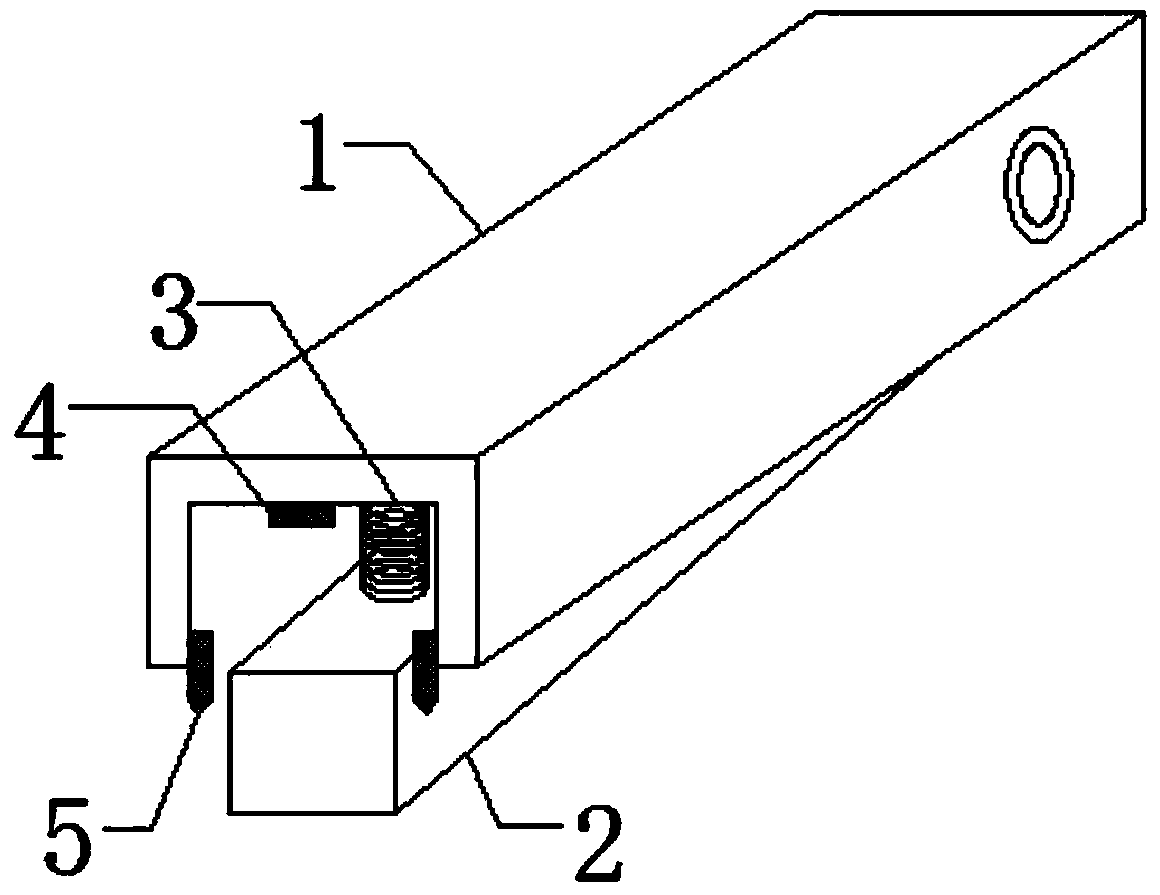

[0018] Embodiment 1: a kind of small diameter square copper pipe tearing device, its structure is as figure 1 As shown: it includes a rectangular gland 1 inside, the rear end of the gland 1 is hinged to a cuboid liner 2, a splitting edge 5 is provided on both sides of the inner wall of the gland 1, and the gap between the two splitting edges 5 is The distance is greater than the width of the cuboid-shaped lining 2, and a spring 3 connects the gland 1 with the cuboid-shaped lining 2; the inner wall of the front end of the gland is provided with a sticky substance 4.

[0019] The sticky substance 4 is a self-adhesive.

[0020] The lengths of the two cutting edges 5 are the same.

[0021] The present invention also provides a method for using the small-diameter square copper pipe tearer of this embodiment, the steps are as follows:

[0022] A. Insert the cuboid liner 2 into the inner wall of the copper pipe to be cut;

[0023] B. Press the cover 1 down firmly, so that the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com