Optical fiber drawing device and drawing method thereof

A wire drawing and optical fiber technology, applied in the field of optical fiber manufacturing, can solve the problems of changing the process gas flow rate and ratio, and achieve the effect of reducing production costs and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

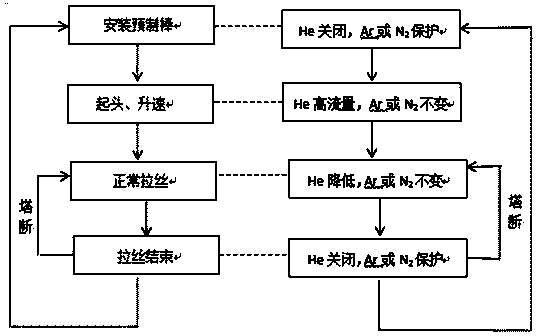

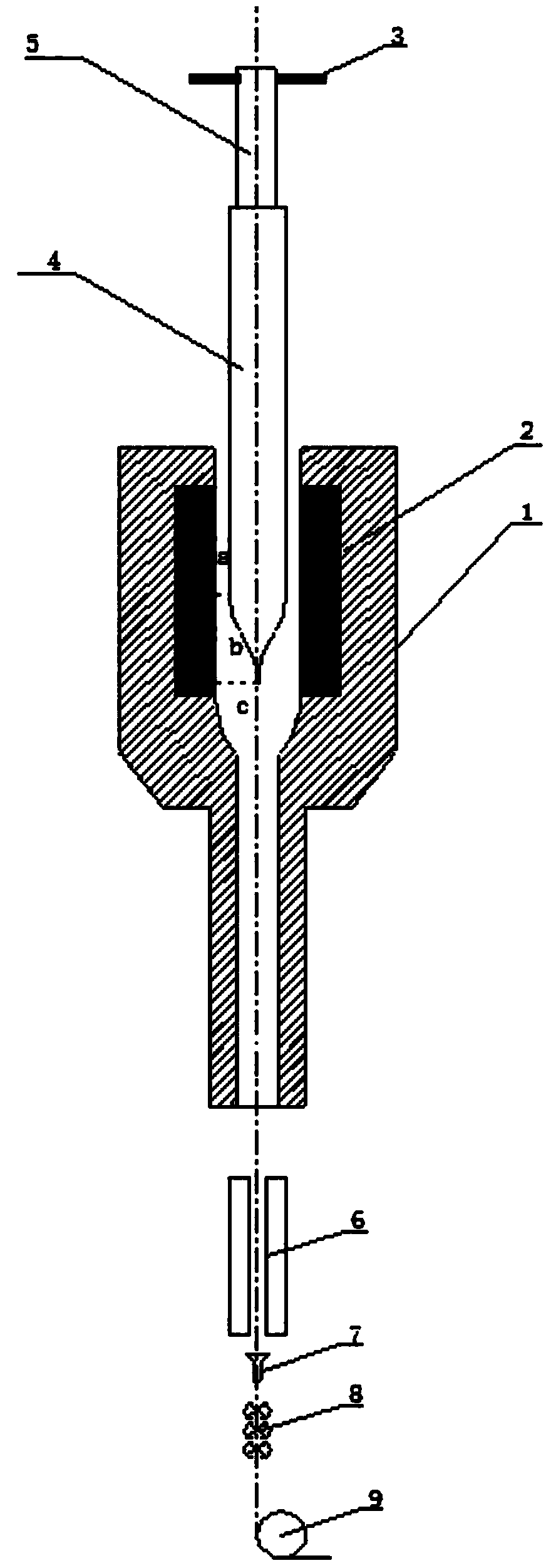

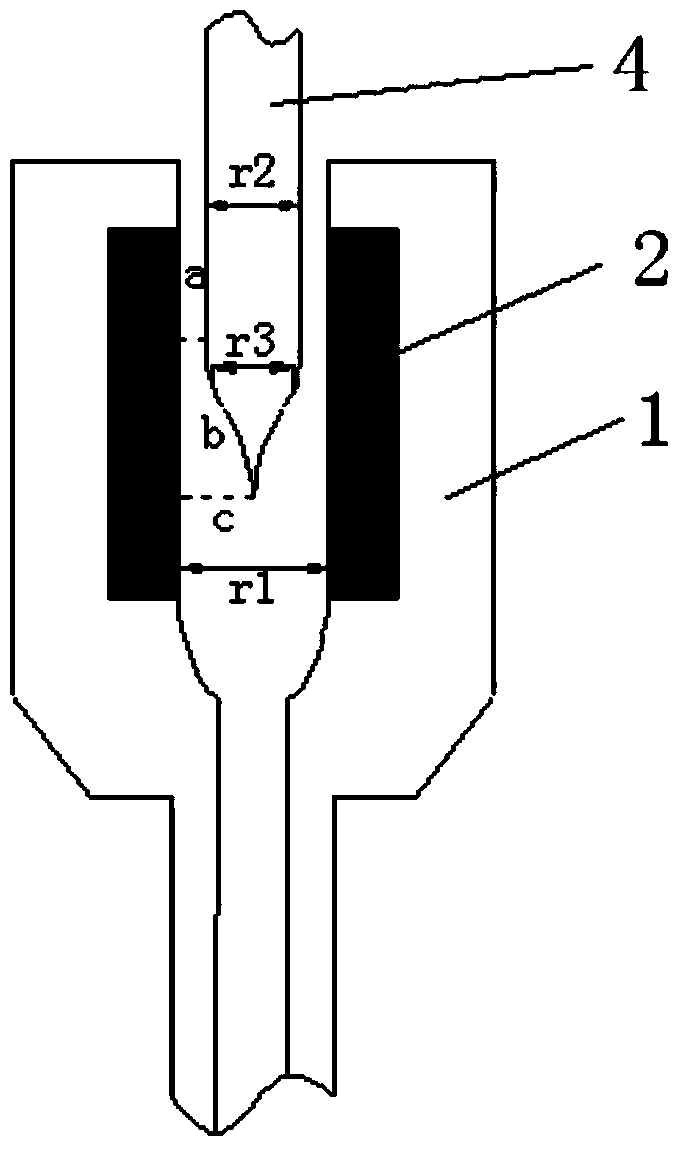

[0040] like Figure 4 As shown, use an optical fiber preform with an outer diameter of 140mm for drawing, and select the inner diameter r of the graphite heating element 1 It is 164mm. In order to ensure the normal drawing stage, the gas flow rate of helium in the fiber forming area is not less than 0.15m / min. According to V=0.15*π*r 1 2 / 4 Calculate the flow rate of helium gas in the inert protective gas into the wire drawing furnace to be 3.2L / min. The wire drawing furnace softens the optical fiber preform, pulls out the optical fiber with the required diameter, cools it through the cooling pipe, and coats the coating with a protective coating. The effectively deposited part of the rod is all drawn into a qualified fiber, and the drawing furnace is closed. During the wire drawing process, when the temperature of the wire drawing furnace is lower than 1500℃, the control device will automatically recognize that this stage is in the furnace shutdown stage, and only pass in a...

Embodiment 2

[0043] like Figure 7 As shown, use an optical fiber preform with an outer diameter of 180mm for drawing, and select the inner diameter r of the graphite heating element 1 It is 216mm. In order to ensure the normal drawing stage, the gas flow rate of helium in the fiber forming area is not less than 0.15m / min. According to V=0.15*π*r 1 2 / 4 Calculate the flow rate of helium gas in the inert protective gas into the wire drawing furnace to be 5.5L / min. During the wire drawing process, when the temperature of the wire drawing furnace is lower than 1500℃, the control device will automatically recognize that this stage is in the furnace shutdown stage, only pass in argon or nitrogen protection, and turn off the helium gas; when the temperature of the wire drawing furnace is greater than 1500℃, and the speed is less than or equal to 1800m / min, the control device automatically recognizes that this stage is in the starting and speed-up stages (including the heating-up U-turn stage,...

Embodiment 3

[0046] like Figure 10 As shown, use an optical fiber preform with an outer diameter of 200mm for drawing, and select the inner diameter r of the graphite heating element 1 It is 226mm. In order to ensure the normal drawing stage, the gas flow rate of helium in the fiber forming area is not less than 0.15m / min. According to V=0.15*π*r 1 2 / 4 Calculate the flow rate of helium gas in the inert protective gas into the wire drawing furnace to be 6L / min. During the wire drawing process, when the temperature of the wire drawing furnace is less than 1500℃, the control device will automatically recognize that this stage is in the furnace shutdown stage, only pass in argon or nitrogen protection, and turn off the helium gas; when the temperature of the wire drawing furnace is greater than 1500℃, and the speed is less than or equal to 2000m / min, the control device automatically recognizes that this stage is in the starting and speed-up stages (including the heating-up U-turn stage, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap