A Large Gas Turbine Air Intake System

A gas turbine and air intake system technology, which is applied to the air inlet of the turbine/propulsion device, charging system, combustion air/combustion-air treatment, etc. The problem of frequent replacement of the device is to achieve the effect of good effect, simple and effective structure and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

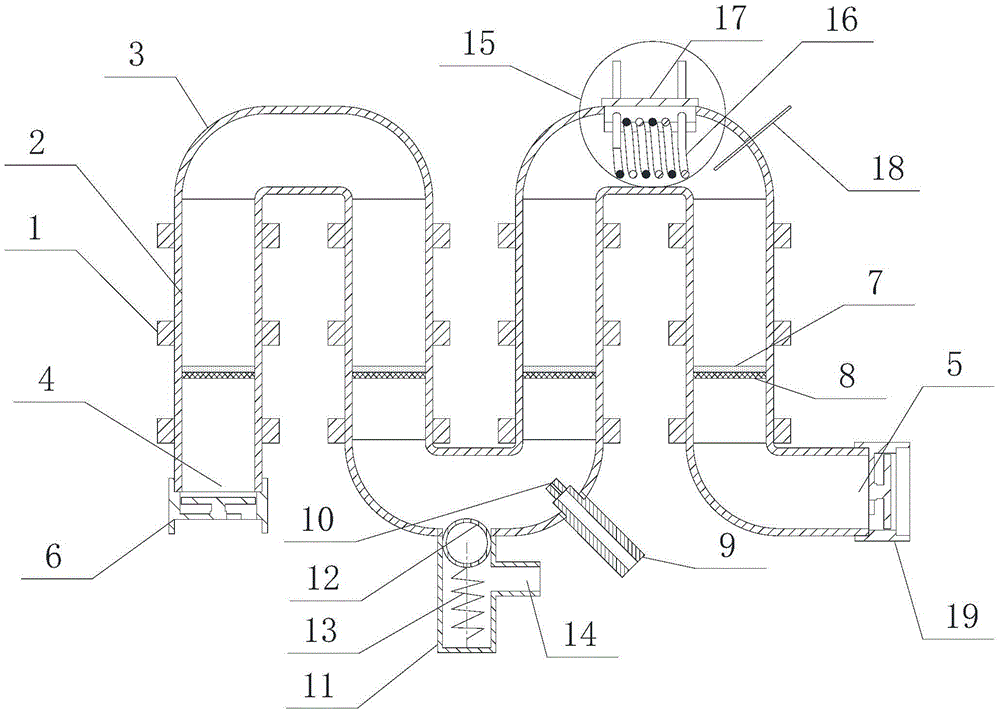

[0018] This embodiment provides a large-scale gas turbine air intake system. An air filter is provided at the air inlet of the large-scale gas turbine. The air filter is composed of a filter tube and a permanent magnet 1 that is sleeved on the outer circle of the filter tube. The filter tube consists of four pieces arranged side by side. The air pipe 2 and the bent pipe 3 arranged vertically are composed, the two adjacent air pipes 2 are connected through the bent pipe 3, the air inlet 4 is provided at one end of the filter, and the air outlet 5 is provided at the other end, the outer surface of the air pipe 2 The circle is equipped with permanent magnets 1, and the permanent magnets 1 are arranged at equal intervals. The air inlet 4 is provided with a first axial flow fan 6; Composed of asbestos net 8;

[0019] A water inlet pipe 9 is arranged on the elbow 3 at the lower end of the air pipe 2, and one end of the water inlet pipe 9 extends into the elbow 3, and an atomizing no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com