Few-tooth-difference speed reducer capable of reducing noise and wear

A technology with less tooth difference and reducer, which is applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., and can solve the problems of reducing product service life and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

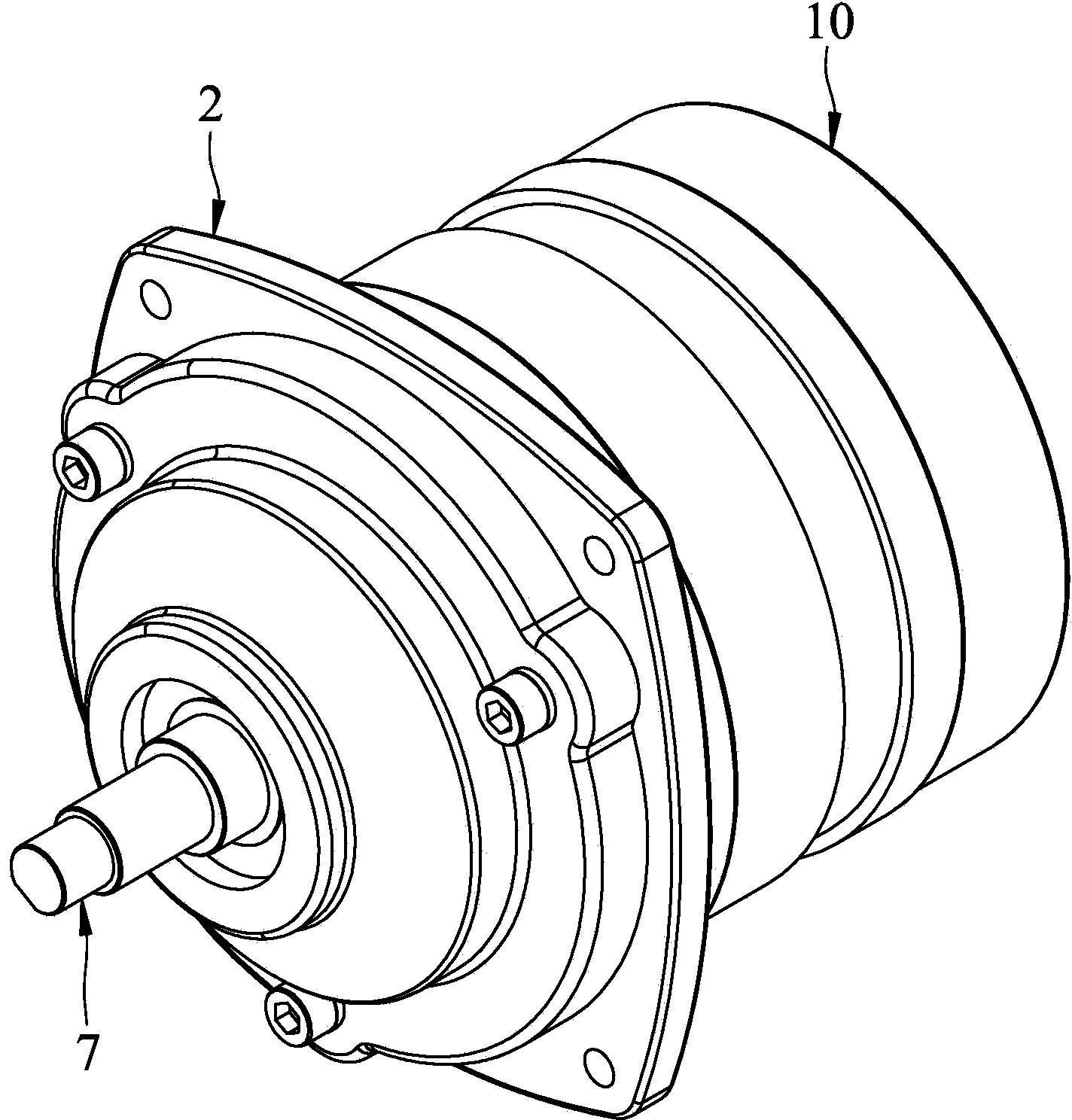

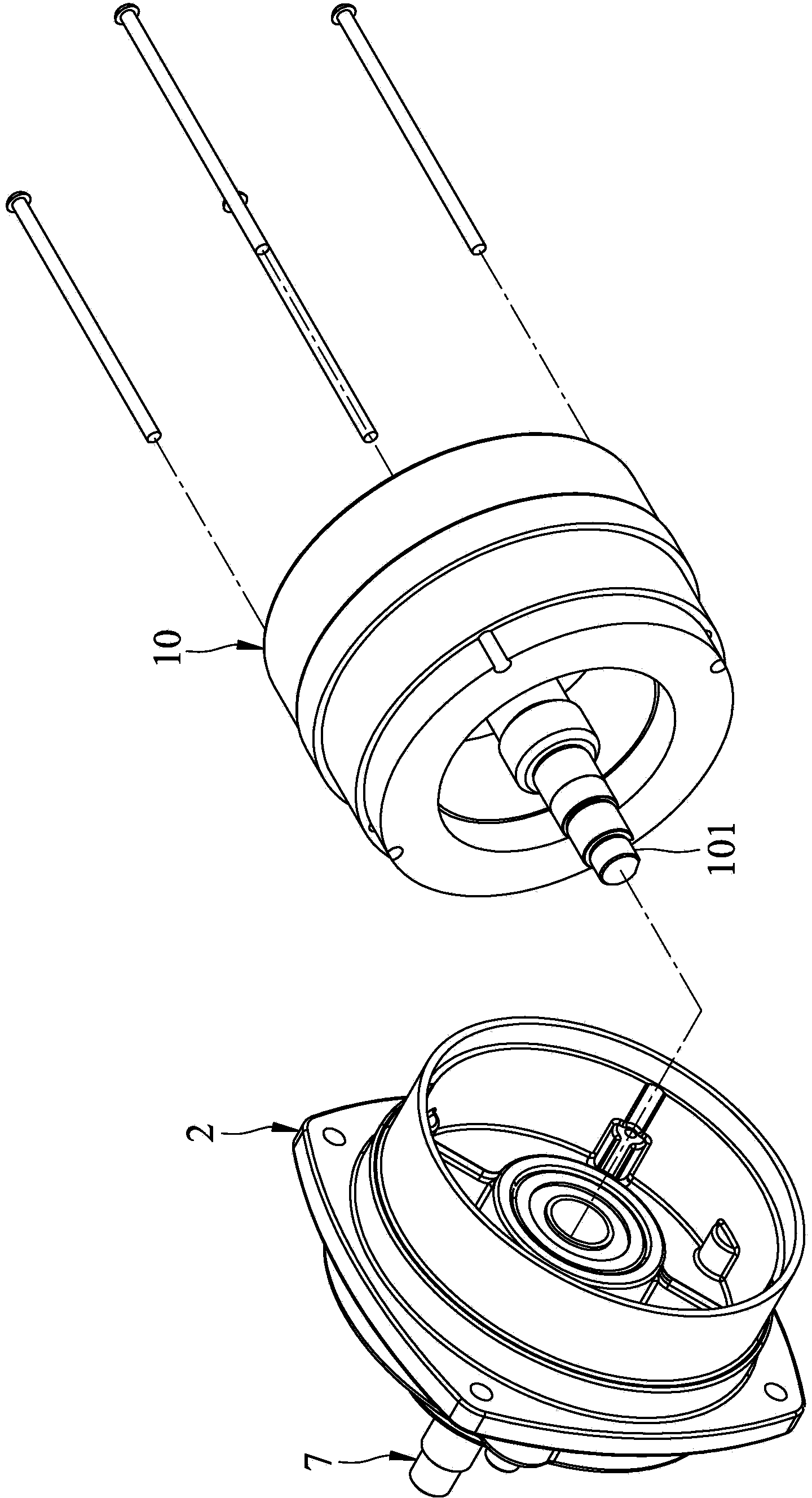

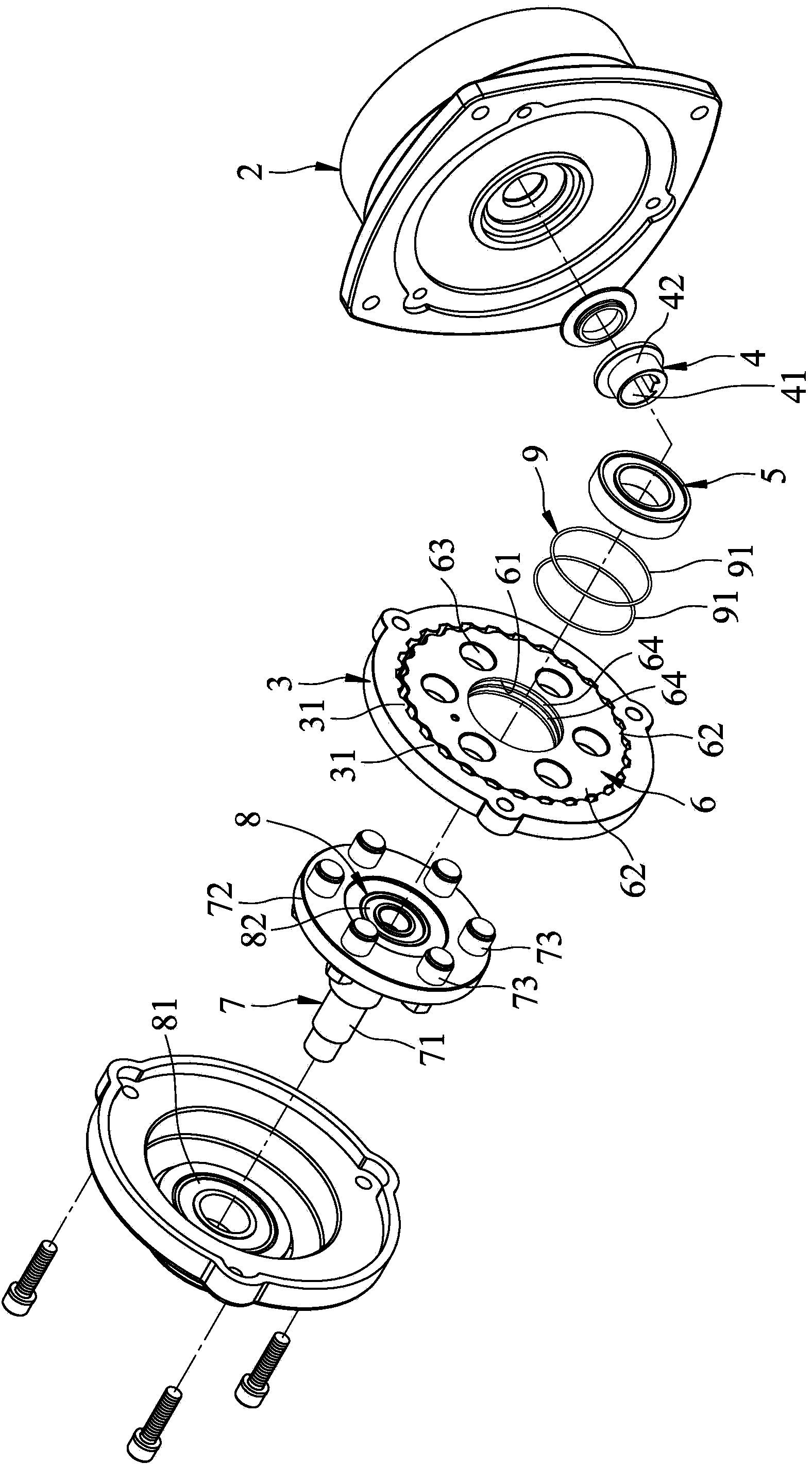

[0035] Such as figure 1 , figure 2 and image 3 As shown, the present invention can reduce the noise and wear of the reducer with small tooth difference, which is suitable for connecting an input shaft 101 of a motor 10, and includes a housing 2, an internal gear 3, an eccentric body 4, and a pivot Part 5, an external gear 6, an output shaft 7, a pivot unit 8, and a shock-absorbing unit 9.

[0036] Such as image 3 , Figure 4 ,and Figure 5 As shown, the internally toothed gear 3 is disposed on the housing base 2 and is integrally formed, and includes a plurality of internal teeth 31 .

[0037] The eccentric body 4 is arranged on the input shaft 101 at a distance from the internal gear 3, and can rotate synchronously with the input shaft 101, and includes an inner ring surface 41 adjacent to the input shaft 101, and an inner ring surface 41 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com