Peripheral drive mud scraper

A mud scraper and mud scraper technology, which is applied to the feeding/discharging device, chemical instrument and method, and separation method of the settling tank. It can solve the problems of easy damage to the scraper and easy burnout of the motor, and prevent Burning, preventing overload and shutdown, avoiding the effect of being burned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

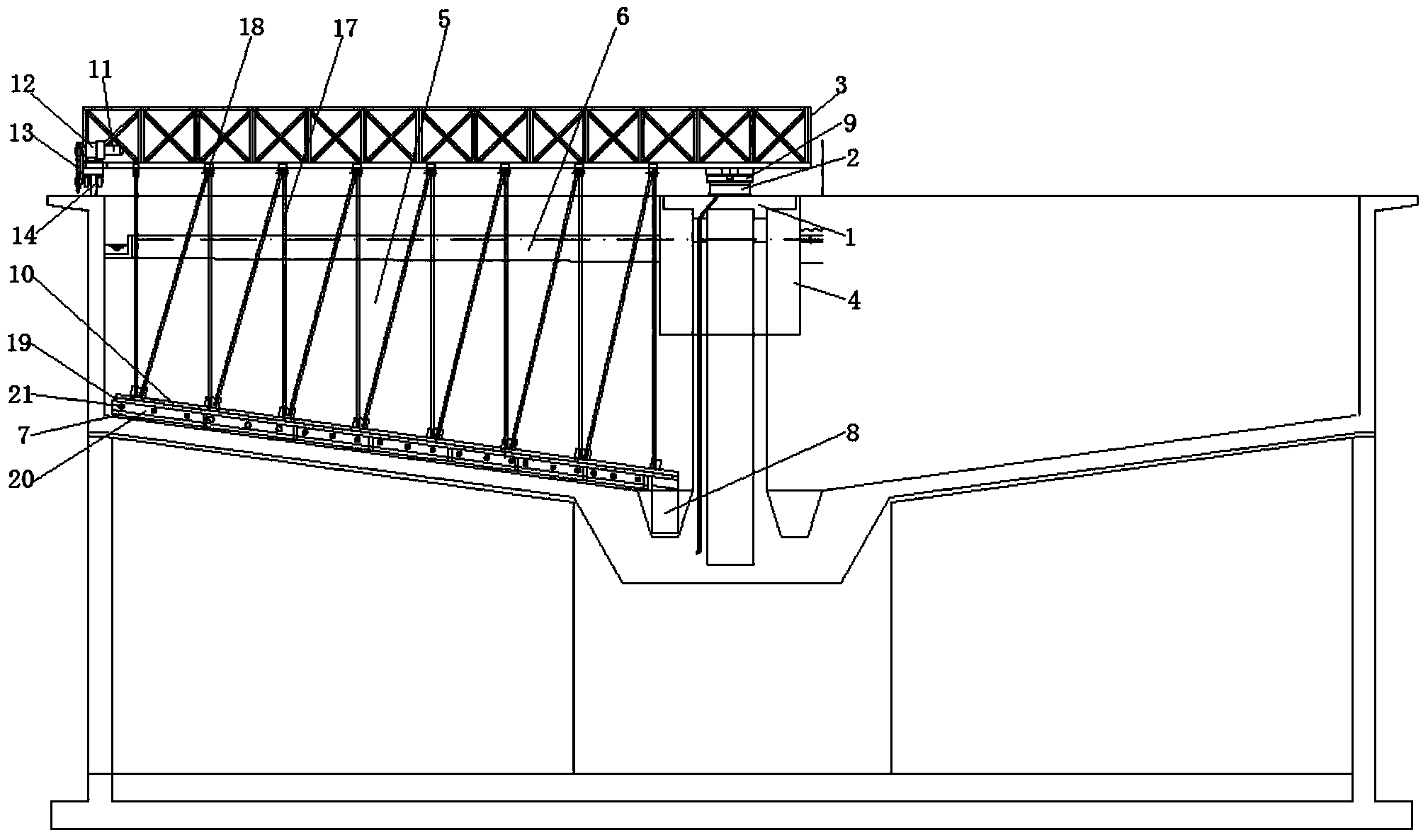

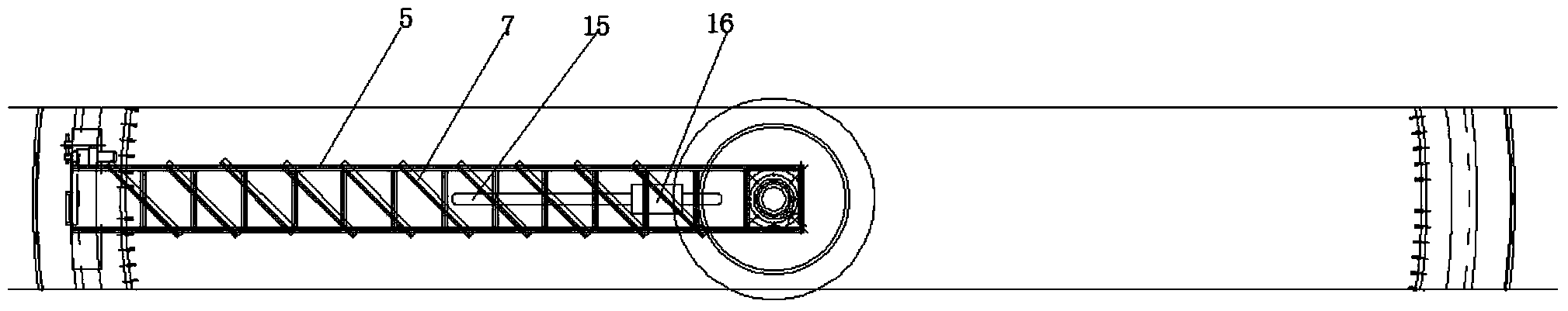

[0015] refer to figure 1 and figure 2 The peripheral driven mud scraper shown includes a central support 1, a current collector 2, a working bridge 3, a flow equalizing bucket 4, a scraper arm 5, a scum scraper 6, a mud scraper 7, and a mud collection tank The scraper 8 and the driving parts, the current collector 2 are arranged on the central support 1, and the central support 1 is provided with a central bearing 9 supporting the working bridge 3, and the working bridge 3 and the central support 1 pass through the center The bearing 9 realizes rotation fit, the scraper arm 5 is arranged under the working bridge 3, the scum scraper 6 is arranged in the middle of the scraper arm 5, and the scraper 7 is fixed on the scraper holder below the scraper arm 5 10, the mud collecting tank scraper 8 is fixed on the inner end of the mud scraper fixed frame 10, and the driving part is arranged on the outer end of the working bridge 3, and the driving part includes a motor 11, a reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com