Die cushion force setting apparatus

一种缓冲设备、缓冲力的技术,应用在压力机、冲压机、制造工具等方向,能够解决难提供模具缓冲力精确分布等问题,达到容易输入、平稳模具缓冲力分布的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

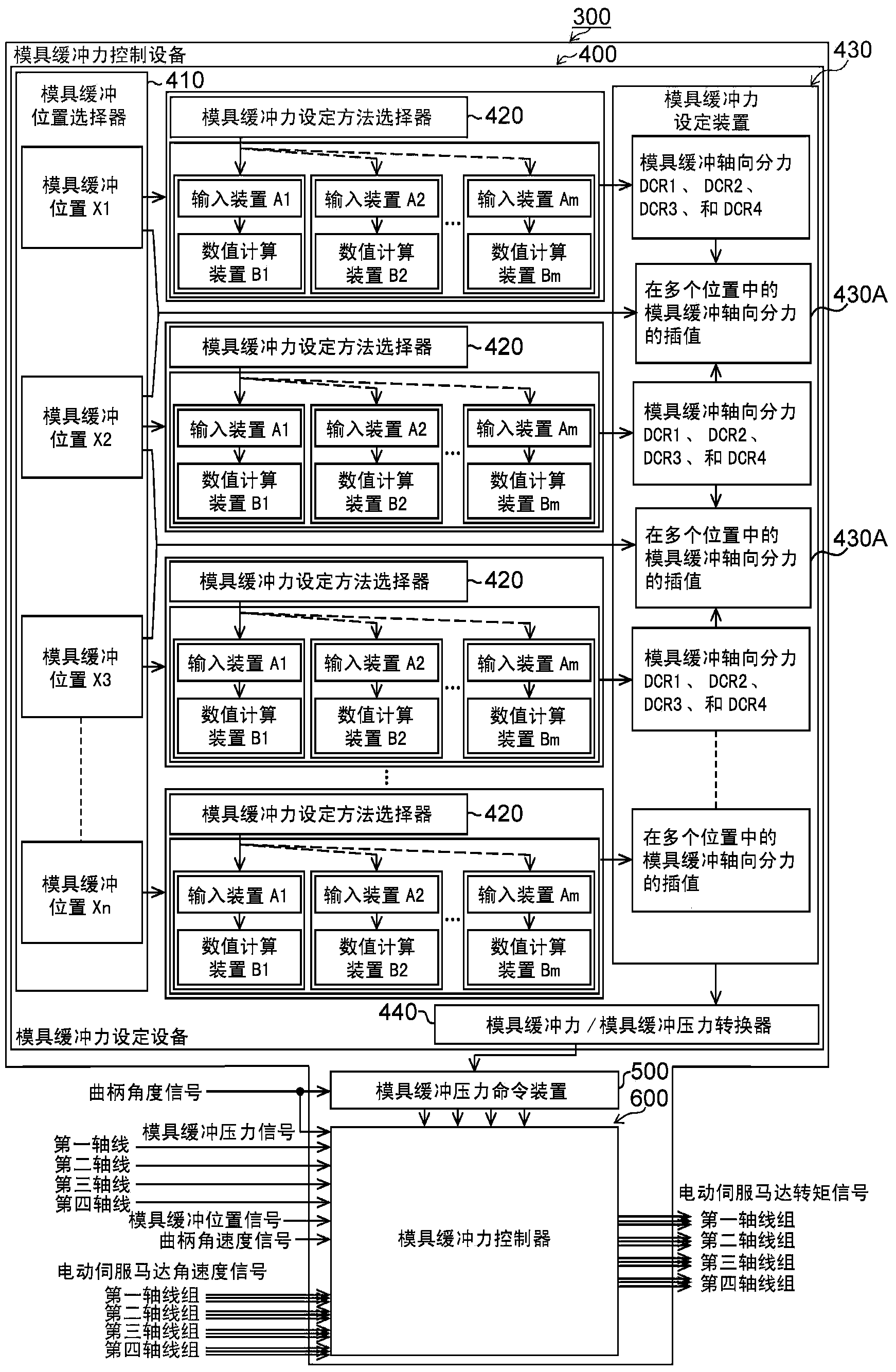

[0029] Preferred embodiments of the die cushion force setting device according to the present invention will be described in detail below with reference to the accompanying drawings.

[0030] First, the die cushioning device of the press machine produced by the die cushioning force setting device according to the present invention will be described.

[0031]

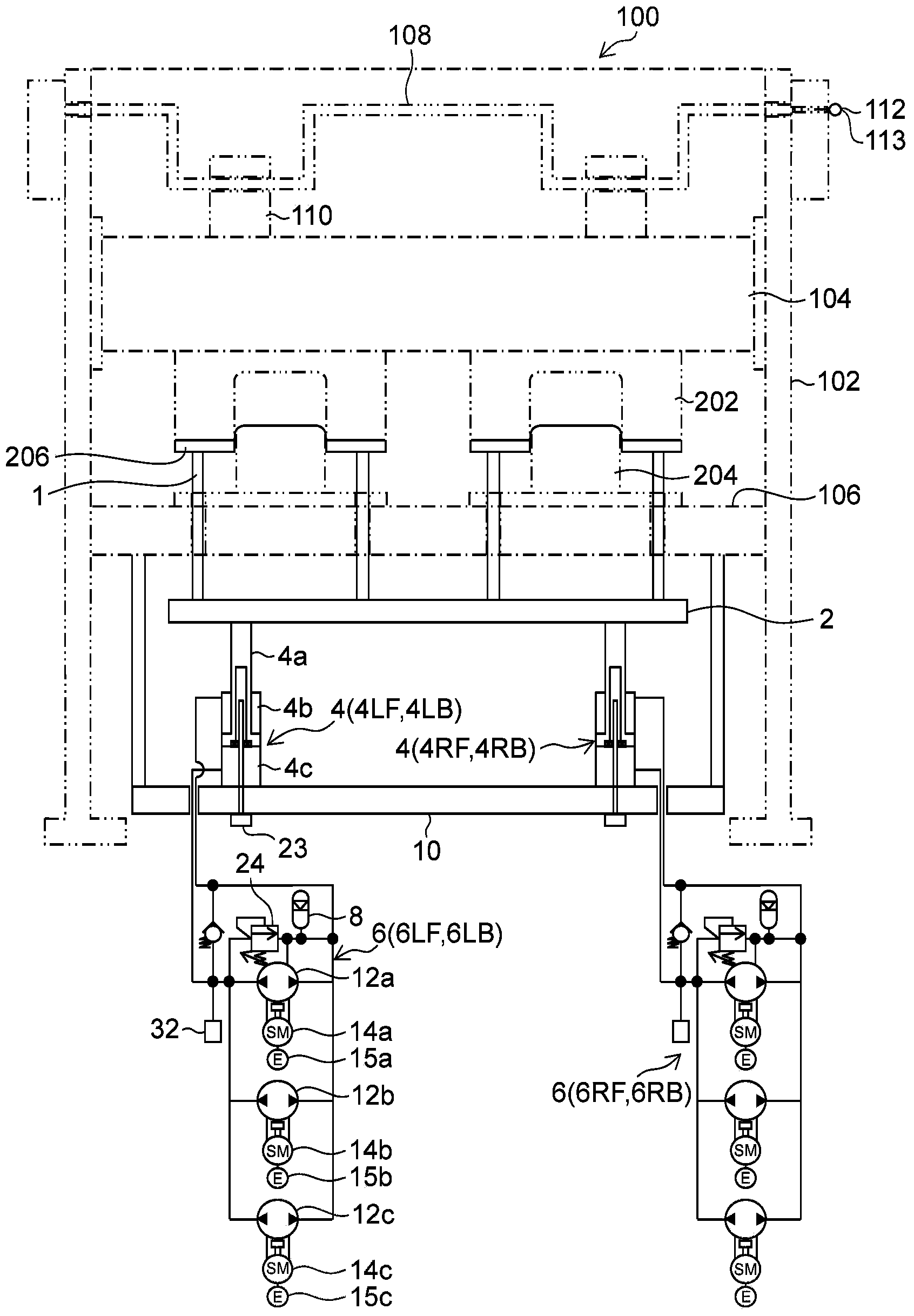

[0032] figure 1 is a block diagram showing one example of a die cushioning device of a press. The main elements of the press are indicated by dotted lines.

[0033] figure 1 The press 100 shown in includes a column (framework) 102, a slide device 104, a bed 106, a crankshaft 108, and a connecting rod 110, and the slide device 104 is movably moved in the vertical direction by a guide unit installed on the column 102. guide. Furthermore, the crankshaft 108 is connected to the sliding device 104 via a connecting rod 110 . The rotational driving force is designed to be transmitted to the crankshaft 108 by the servomot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com