Ultra-abrasion-resistant high-bearing oil-saving environment-friendly van tire

A high-load-bearing, ultra-wear-resistant technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of increased noise, unfavorable drainage, etc., to improve dispersion and control performance , The effect of wetland performance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below according to the drawings and embodiments.

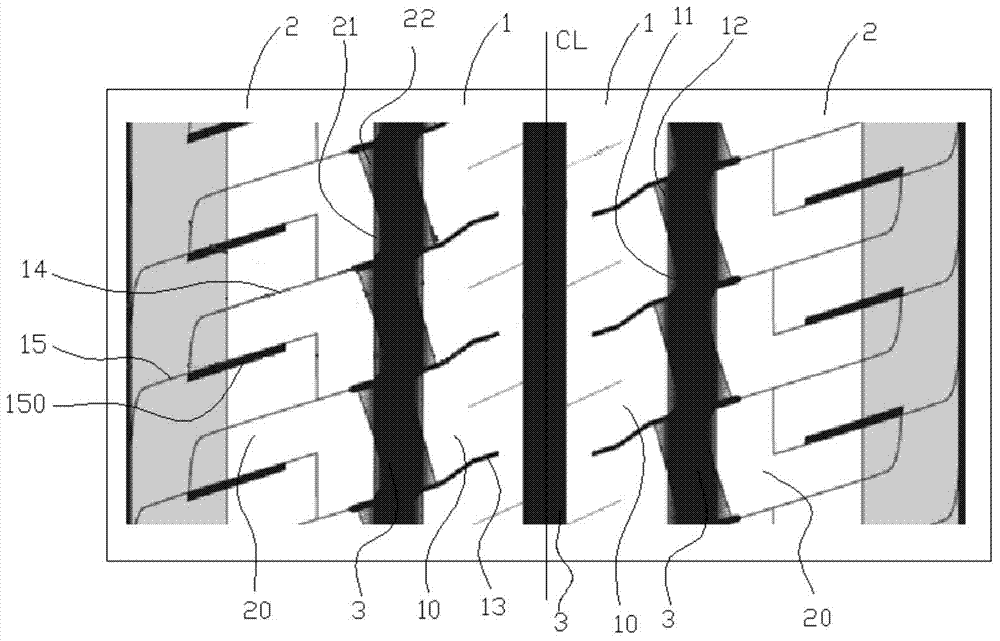

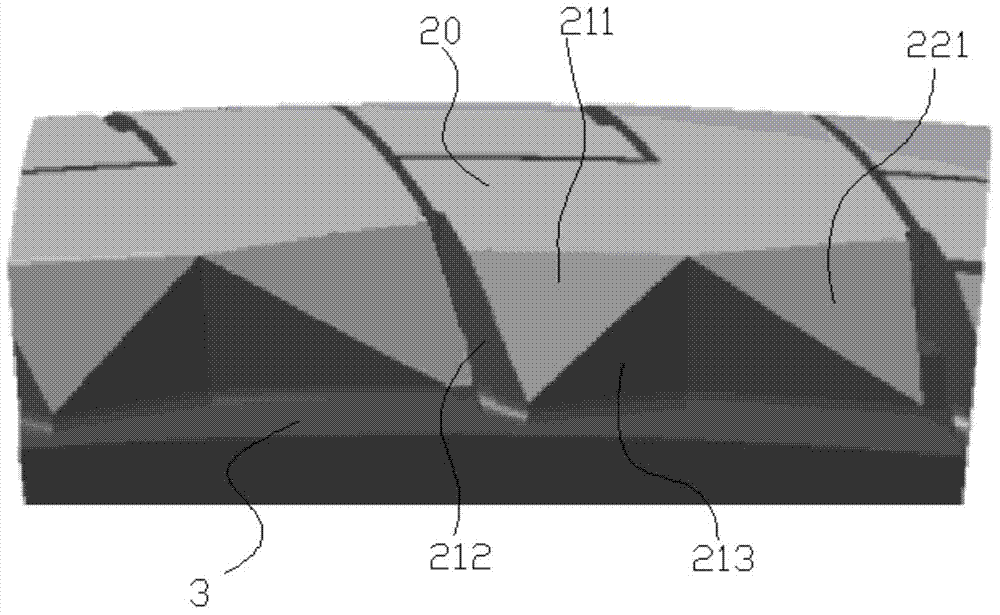

[0019] figure 1 It is a structural schematic diagram of the tire running surface of the super-abrasion-resistant, high-load-bearing, fuel-saving and environment-friendly VAN tire of the present invention, refer to figure 1 , the present invention, a super wear-resistant, high load-bearing, fuel-saving and environment-friendly VAN tire, comprising a tire running surface, a pattern block 1 is arranged on each side of the tire running surface along the center line CL, and shoulder parts 2 are arranged on both sides of the tire running surface The main groove 3 along the running direction of the tire is arranged between the pattern block and the pattern block, between the pattern block and the shoulder part. The blocks 20 are stacked along the tire running direction, and the side faces of the shoulder block 20 and the pitch 10 facing each other are provided with pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com