Embroidery machine

An embroidery machine and embroidery technology, applied in embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve problems such as the complexity of the drive source structure, and achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Hereinafter, an embroidery machine according to an embodiment of the present invention will be described in detail with reference to the drawings.

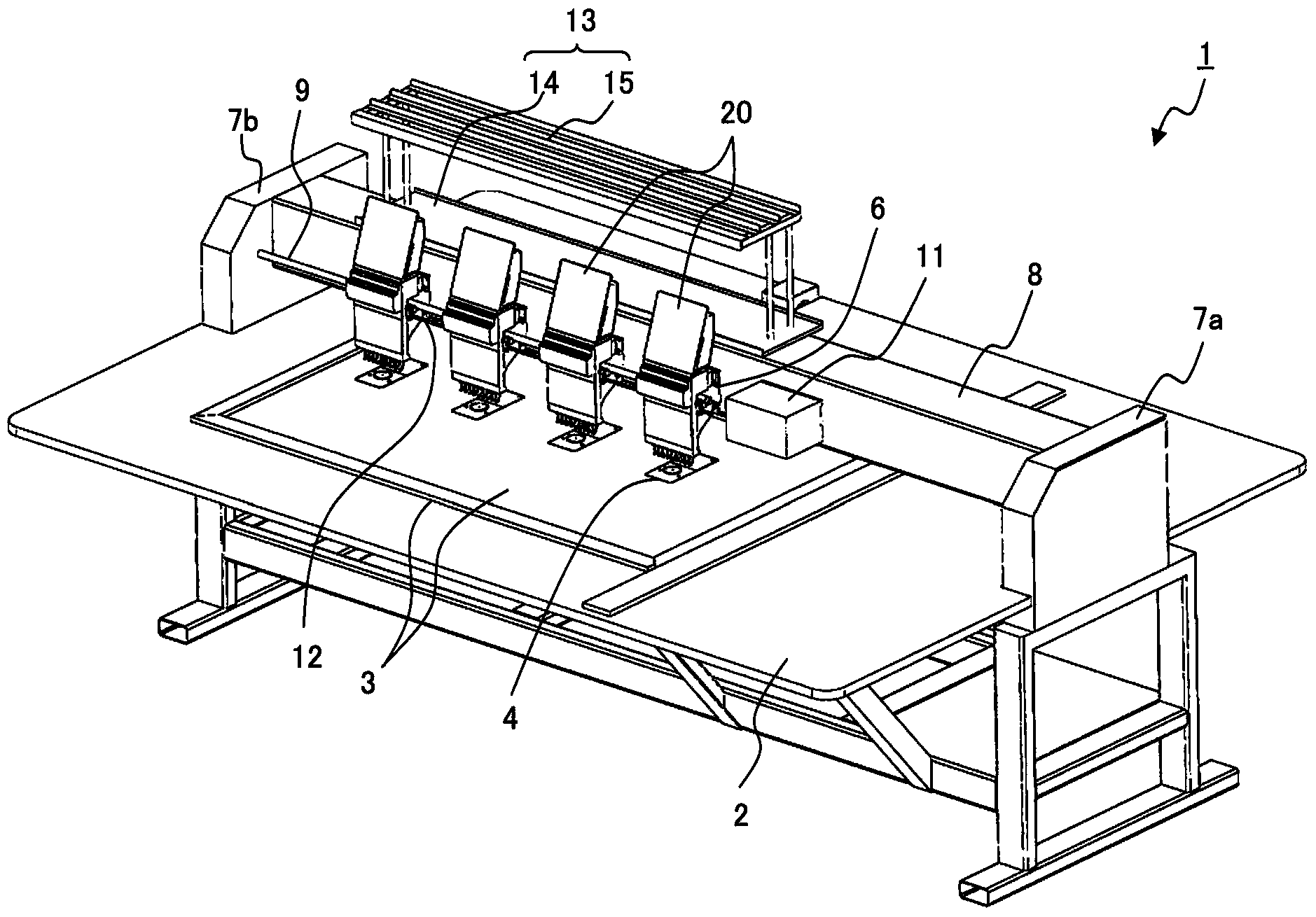

[0079] figure 1 It is a perspective view showing the embroidery machine 1 according to one embodiment of the present invention.

[0080] figure 1 The illustrated embroidery machine 1 is provided with an embroidery machine table 2 and an embroidery frame 3 extending widely at the center of the embroidery machine table 2 .

[0081] On the lower side of the embroidery frame 3, there are multiple figure 1 In the example is 4) lower shuttle part 4. After the embroidery medium is tensioned and set, the embroidery frame 3 can freely move forward, backward, left, and right according to the procedure in the embroidery instruction book.

[0082] In the upper position corresponding to the lower shuttle part 4, there are multiple figure 1 In the example, there are four) the embroidery head 20 described later, the head rail of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com