a prefabricated house

A technology for prefabricated houses and side panels, applied in small buildings, buildings, building structures, etc., can solve problems such as single function, and achieve the effect of expanding the scope of application, improving convenience and safety, and facilitating short-distance movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

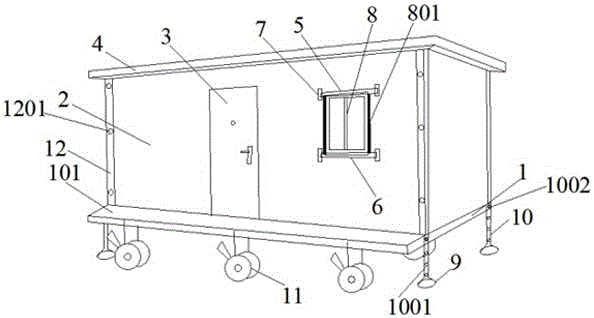

[0018] see figure 1 , a prefabricated house of the present invention, comprising: a bottom assembly, a side assembly and a top assembly. Wherein, the bottom assembly includes: a bottom support frame 1, a bottom support plate (not shown in the figure) fixedly connected with the bottom support frame 1, the bottom support plate is preferably hinged by two support sub-plates through a 180-degree flip hinge , to reduce the occupied space during transportation; the side assembly includes: a plurality of side panels 2 that form a closed body with top and bottom openings after installation, and a door body 3 and at least one window 8 are arranged on the side panel 2; the top assembly includes : a top support frame 4, a top support plate fixedly connected with the top support frame 4, the top support plate is preferably a flame-retardant and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com