Wet clutch

A technology of wet clutches and bearings, which is applied in the field of clutches, can solve the problems of large bite force, short service life, and high replacement cost, and achieve the effects of large transmission torque, improved service life, and smooth and gentle power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

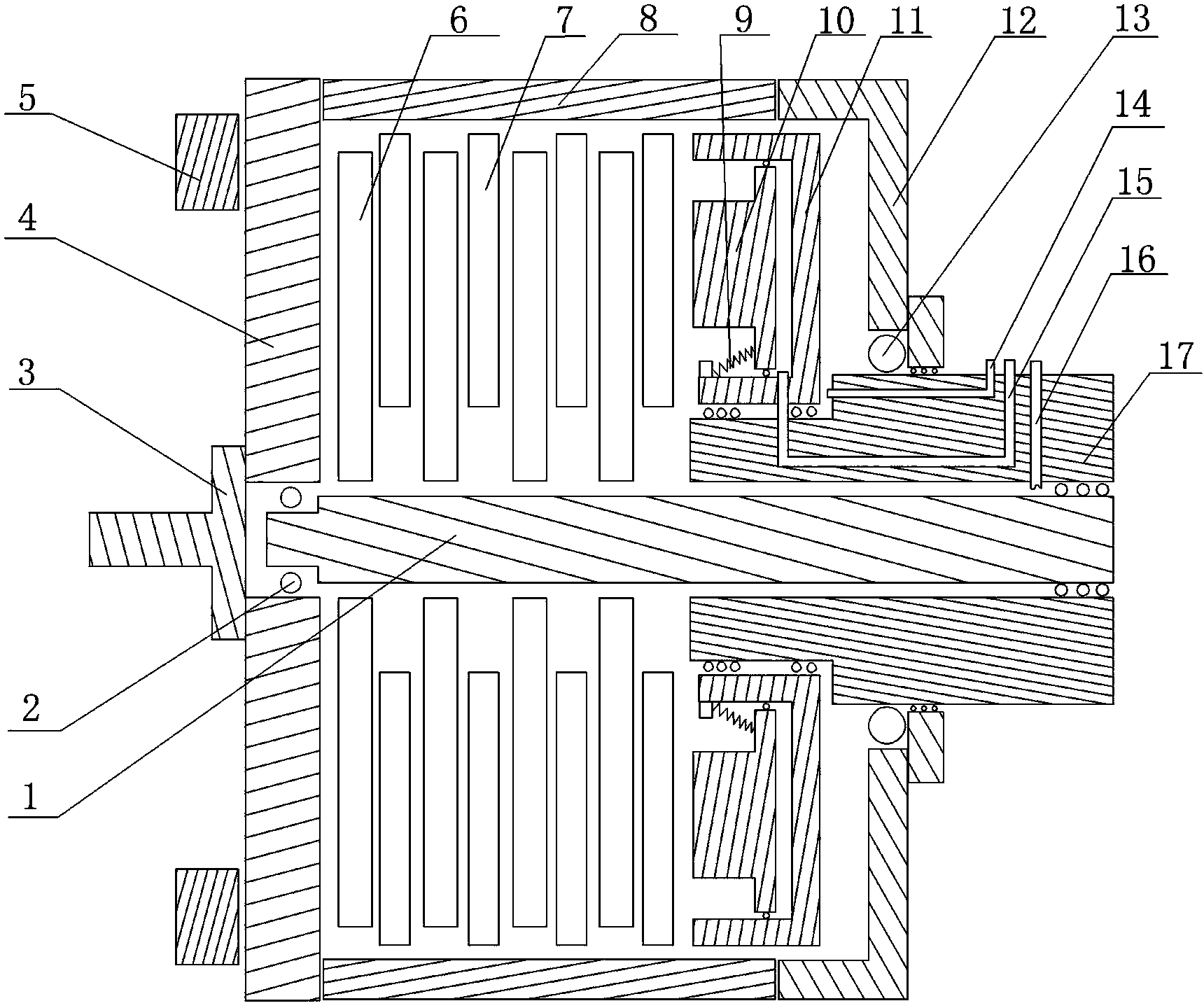

[0009] A wet clutch such as figure 1 As shown, it includes a shaft 1, a shaft bearing 2, a front cover 3, a front housing 4, a connecting gear 5, a driven friction plate 6, an active friction plate 7, an active ring gear 8, a return spring 9, a piston 10, and a joint Cylinder 11, rear shell 12, bearing 13, oil return port 14, connecting oil port 15, cooling oil port 16, a shaft cover 17, a shaft 1 is installed on the gearbox through a shaft bearing 2, and a shaft cover 17 is arranged on On a shaft 1, a joint cylinder 11 and a rear shell 12 are arranged on a shaft cover 17, a bearing 13 is arranged between the rear shell 12 and a shaft cover 17, a piston 10 is arranged in the joint cylinder 11, and the piston 10 and the joint cylinder 11 There is a return spring 9 between them, and a shaft cover 17 is also provided with an oil return port 14, a joint oil port 15, and a cooling oil port 16. The joint oil port 15 communicates with the joint cylinder 11, and the active friction pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com