End plug on soft water valve

A soft water valve and end plug technology, applied in the field of end plugs, can solve the problems of unstable sealing effect, leakage, leakage of piston rod, etc., and achieve the effect of solving the problem of end plug leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

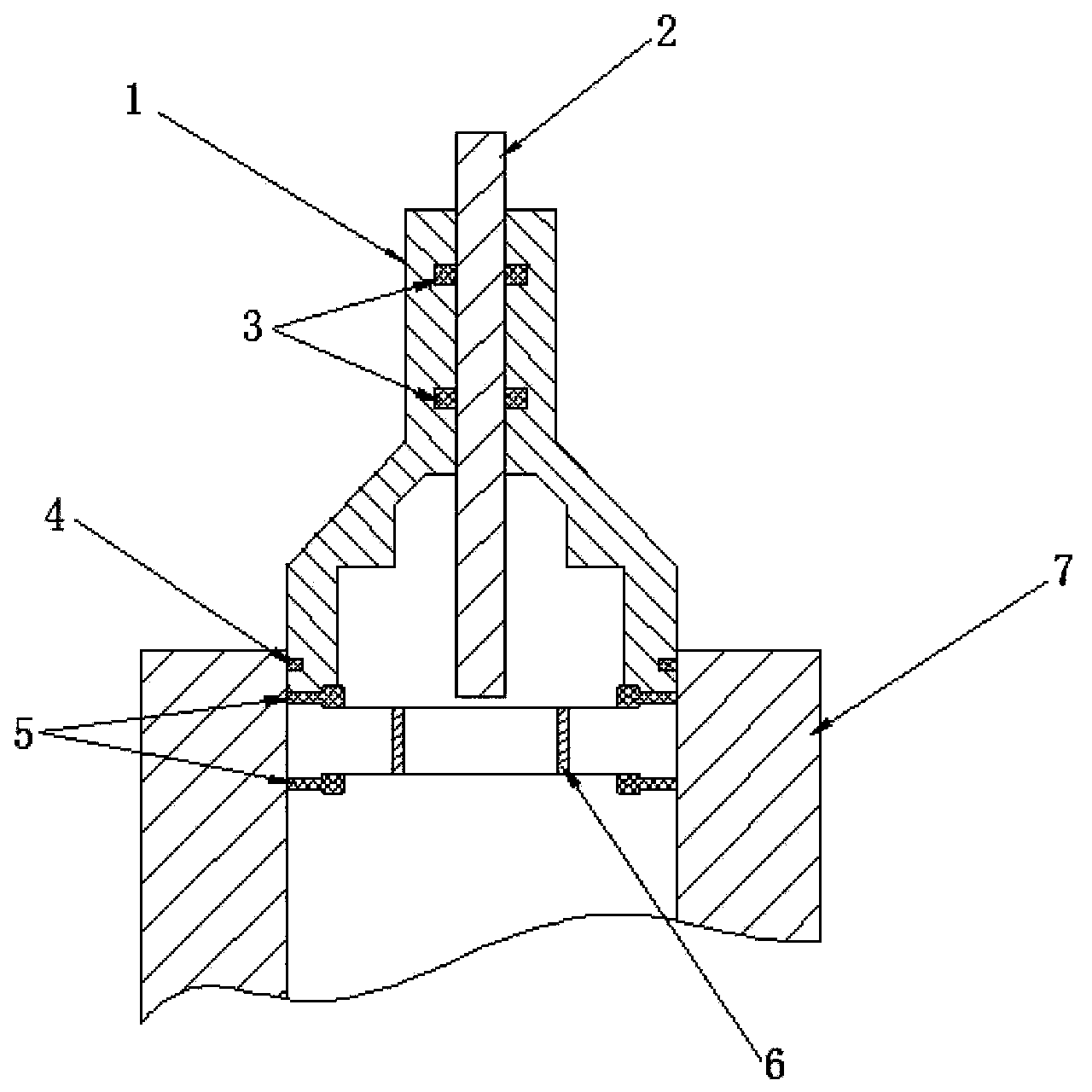

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 Shown: an end plug on a soft water valve, including an end plug main body 1, a small O-ring 3, a large O-ring 4, a gasket 5 and a grille 6; the top of the end plug main body 1 is provided with a hole, so Two small O-rings 3 are provided on the inner wall of the hole, a large O-ring 4 is provided at the bottom of the end plug main body 1, and a grid 6 is also provided at the bottom of the end plug main body 1, and the grid The outside of 6 is provided with two gaskets 5.

[0013] Grooves are provided on the outer side of the grille 6, and the two gaskets 5 are engaged with the grille 6 to enhance the sealing performance.

[0014] The hole matches the external piston rod 2 , and the bottom end of the piston end plug main body 1 matches the port of the valve body 7 .

[0015] The boundary between the sealing gasket 5 and the large O-ring 4 is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap