Cover-cap for cylindrical battery and cylindrical battery

A technology for cylindrical batteries and caps, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of increasing the proportion of scrapped or defective products, excessive liquid injection, and less liquid injection, so as to reduce the proportion of scrapped and defective products, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

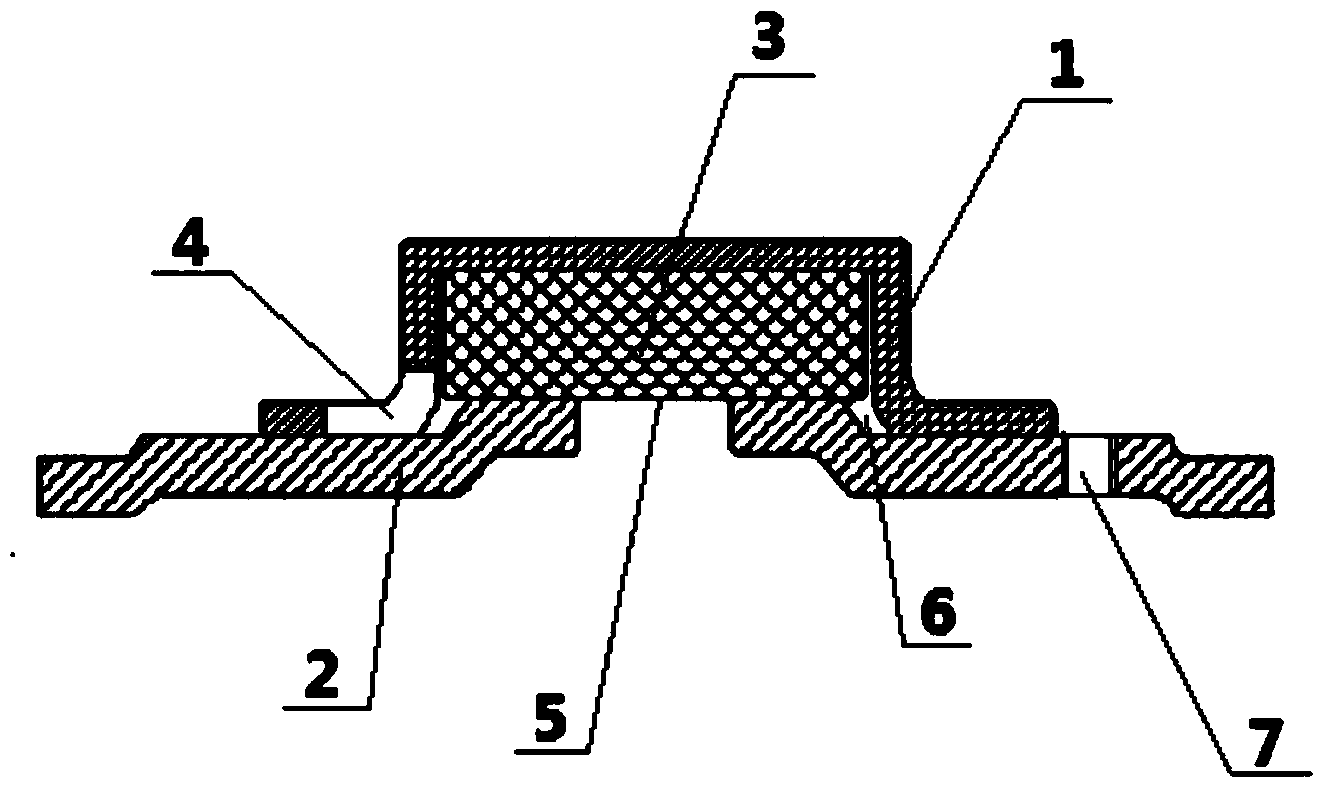

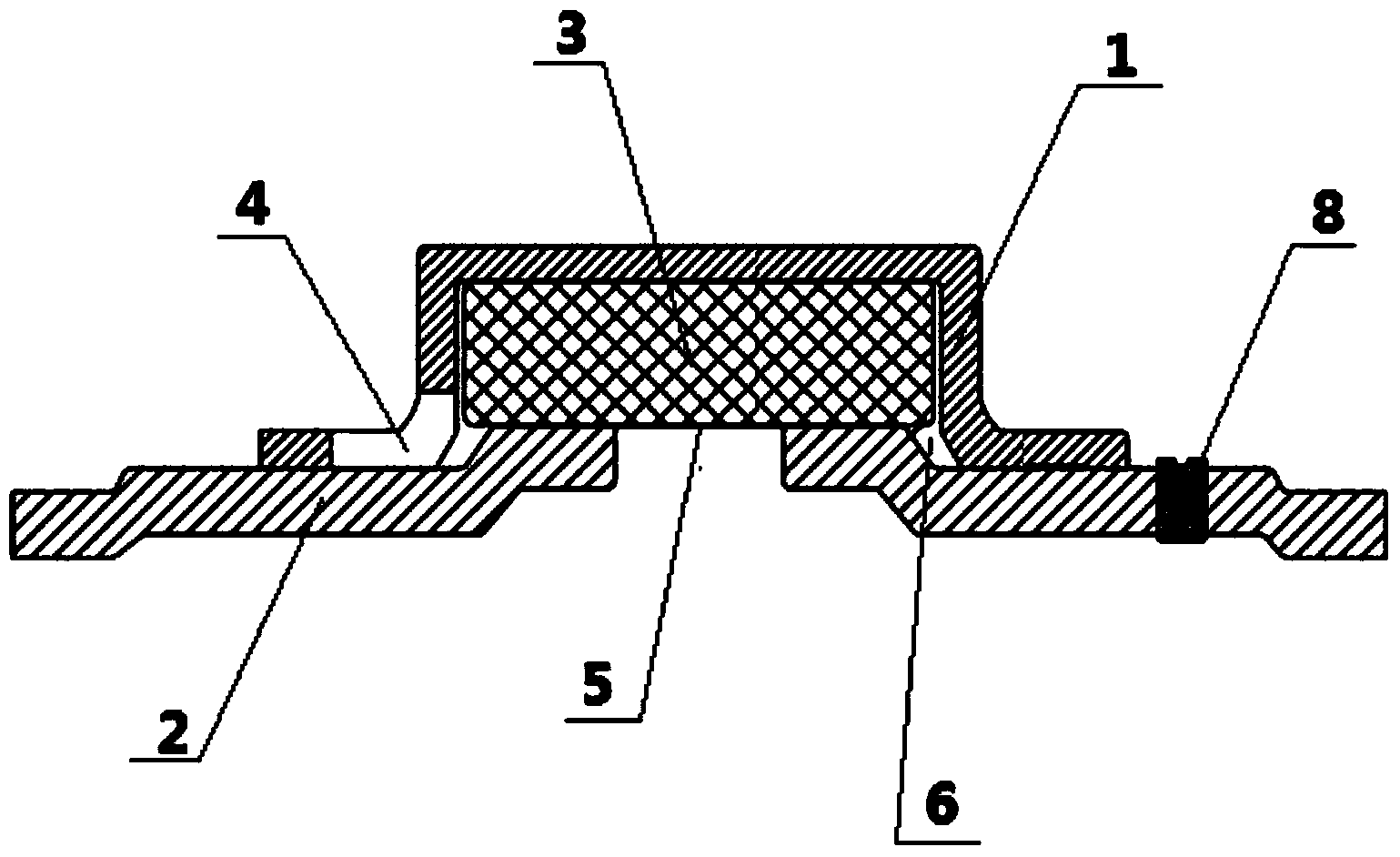

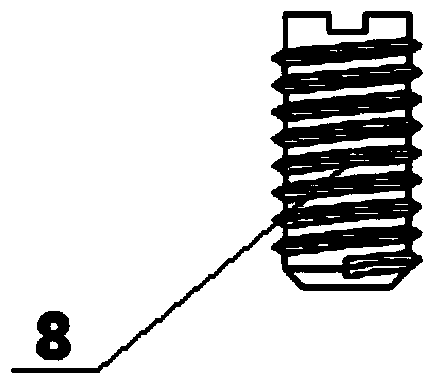

[0016] A cap for a cylindrical battery, such as figure 1 , figure 2 As shown, it includes an upper cap 1, a lower cover 2, and an explosion-proof ball 3. The upper cap 1 and the lower cover 2 are tightly combined. An air vent 4 is provided on the side of the upper cap 1, and a vent hole 4 is provided in the center of the lower cover. Explosion-proof holes 5, an accommodation space 6 is formed between the upper cap 1 and the lower cover 2, the explosion-proof ball 3 is placed in the accommodation space 6, and a liquid injection hole 7 with a circular cross section is arranged on the side of the lower cover 2, and the injection The liquid hole 7 and the liquid injection valve 8 are tightly matched and closed in a spiral manner. The partial enlarged picture of the liquid injection valve 8 is shown in image 3 shown.

Embodiment 2

[0018] A cylindrical battery cap, the structure of which is similar to the cylindrical battery cap of Example 1, the difference is that two air vents are arranged symmetrically on the side of the upper cap, and symmetrically arranged on the side of the lower cap. There are two injection holes that are circular in cross section.

Embodiment 3

[0020] A cylindrical battery, in which an electric core is placed in the casing, an electrolyte is injected, and a cap is used for sealing the cap. The cap for the cylindrical battery in Example 1 is used as the cap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com