Machine for cleaning needle holder plates for knitting machines

A needle box board, knitting machine technology, applied in the direction of cleaning methods and utensils, cleaning methods using liquids, knitting, etc., can solve the problems of ultrasonic machine influence, unsatisfactory cleaning results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

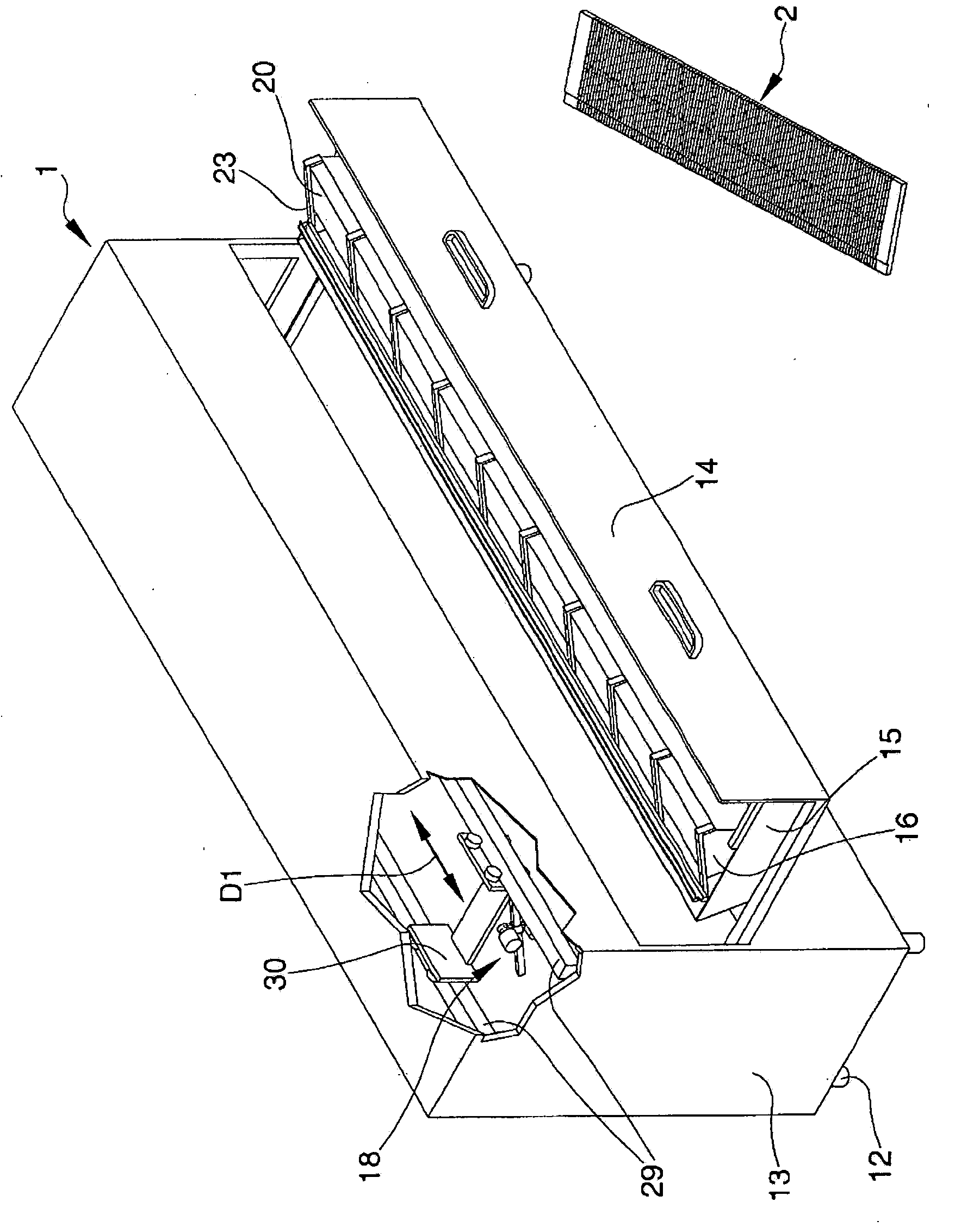

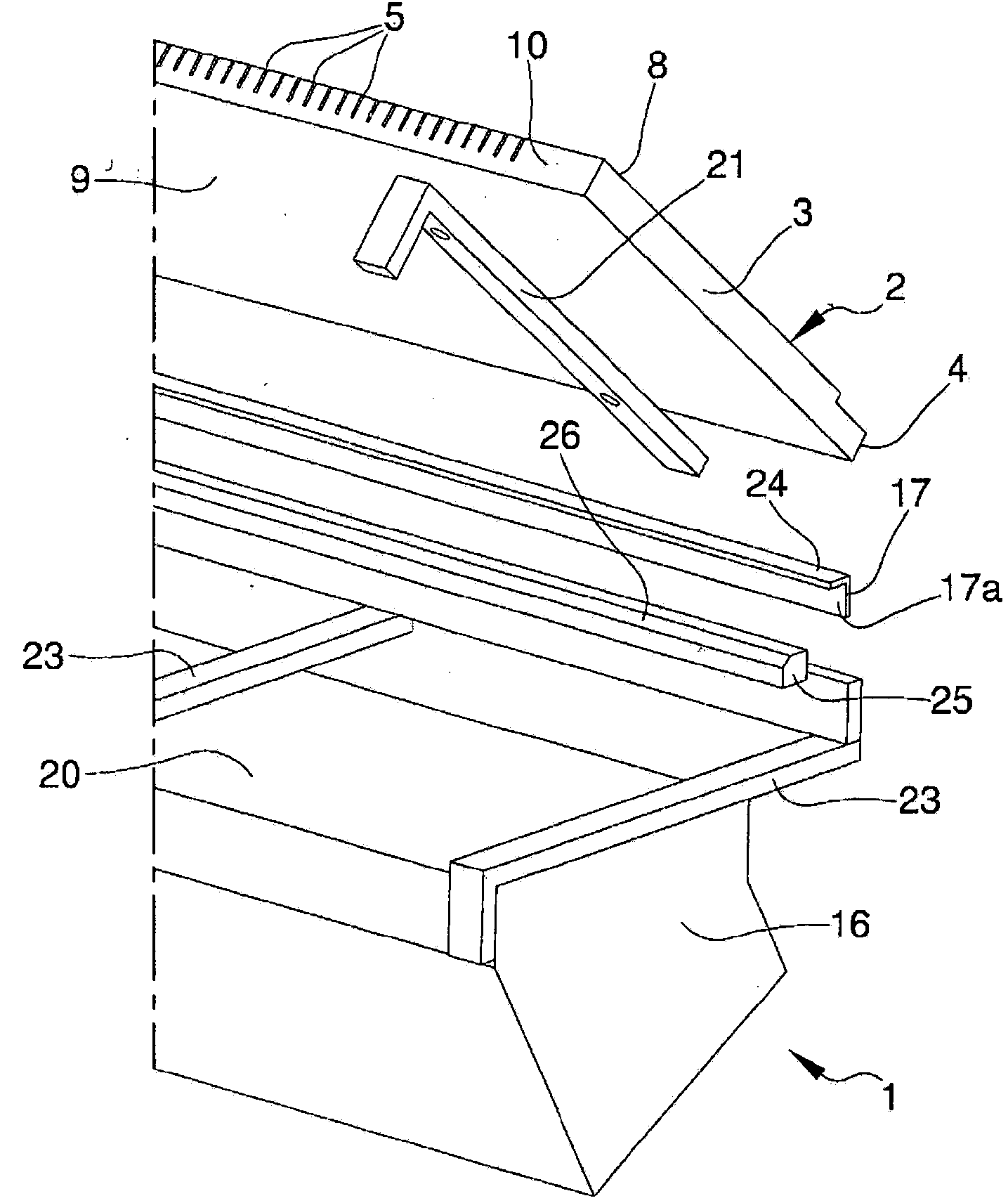

[0032] With particular reference to the accompanying drawings, a machine for cleaning a needle box plate for a knitting machine is indicated generally by 1 .

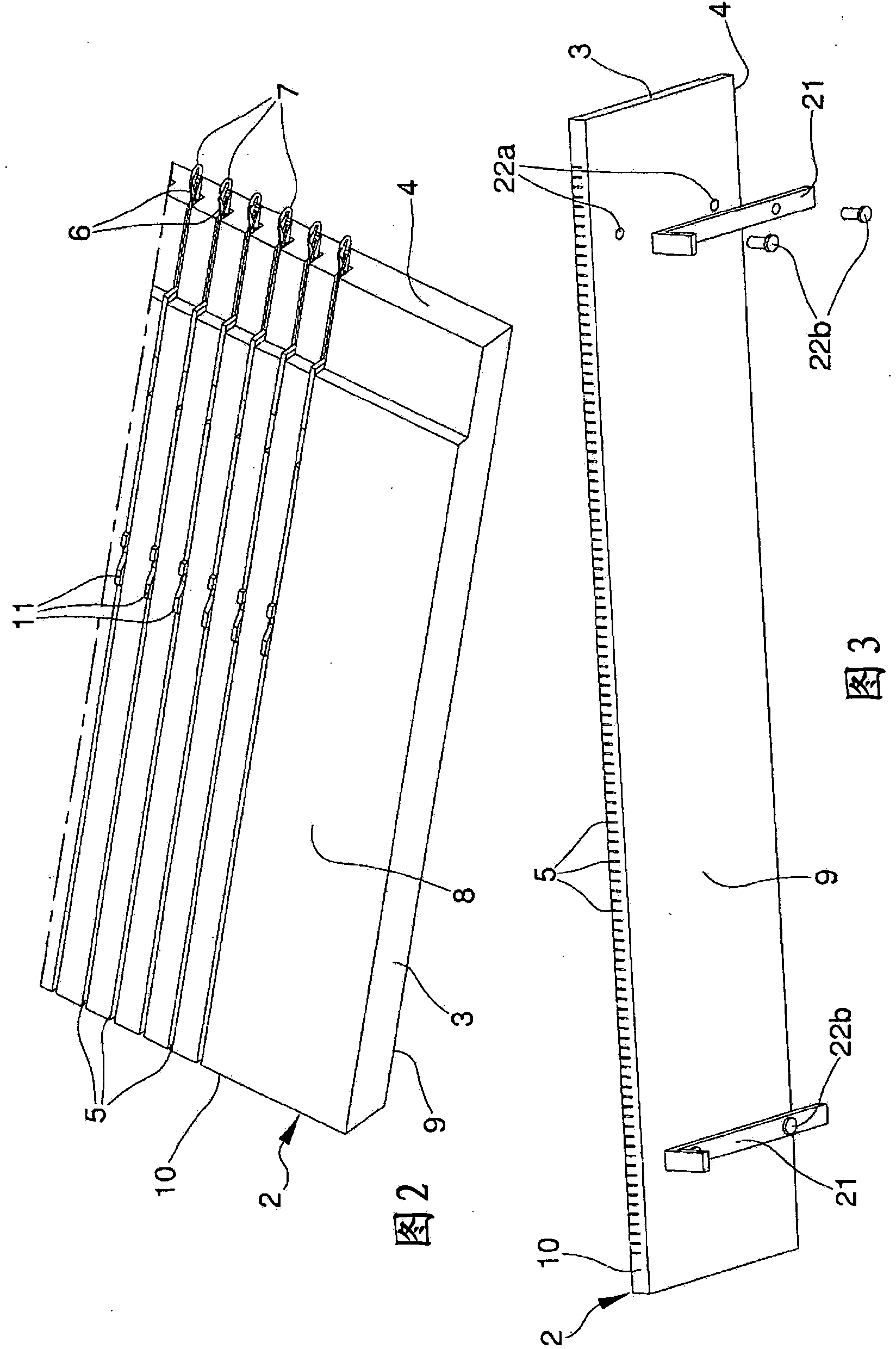

[0033] The machine 1 is especially intended for cleaning one or more needle cassette plates or needle beds 2 comprising:

[0034] - at least a holding plate-like body 3 having a substantially rectilinear working side 4 and a plurality of slots 5 substantially transverse to the working side 4; and

[0035] - A plurality of needles 6 for knitwear slidably housed in the groove 5 and having at least a working end 7 protruding from the working side 4 .

[0036] In more detail, the plate-like body 3 has a first main face 8 and a second main face 9 facing each other.

[0037] The grooves 5 are obtained on the first main face 8 and are all perpendicular to the working side 4 .

[0038] The slot 5 extends from the working side 4 to the opposite side 10 substantially along the entire width of the plate-like body 3 .

[0039] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com