Switching face powder spray head

A technology of switch type and spray head, which is applied in the types of packaging items, cosmetic powder containers, applications, etc., can solve the problems of complex structure, time-consuming and labor-consuming manufacturing, waste, etc., and achieve the effect of simplified structure and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

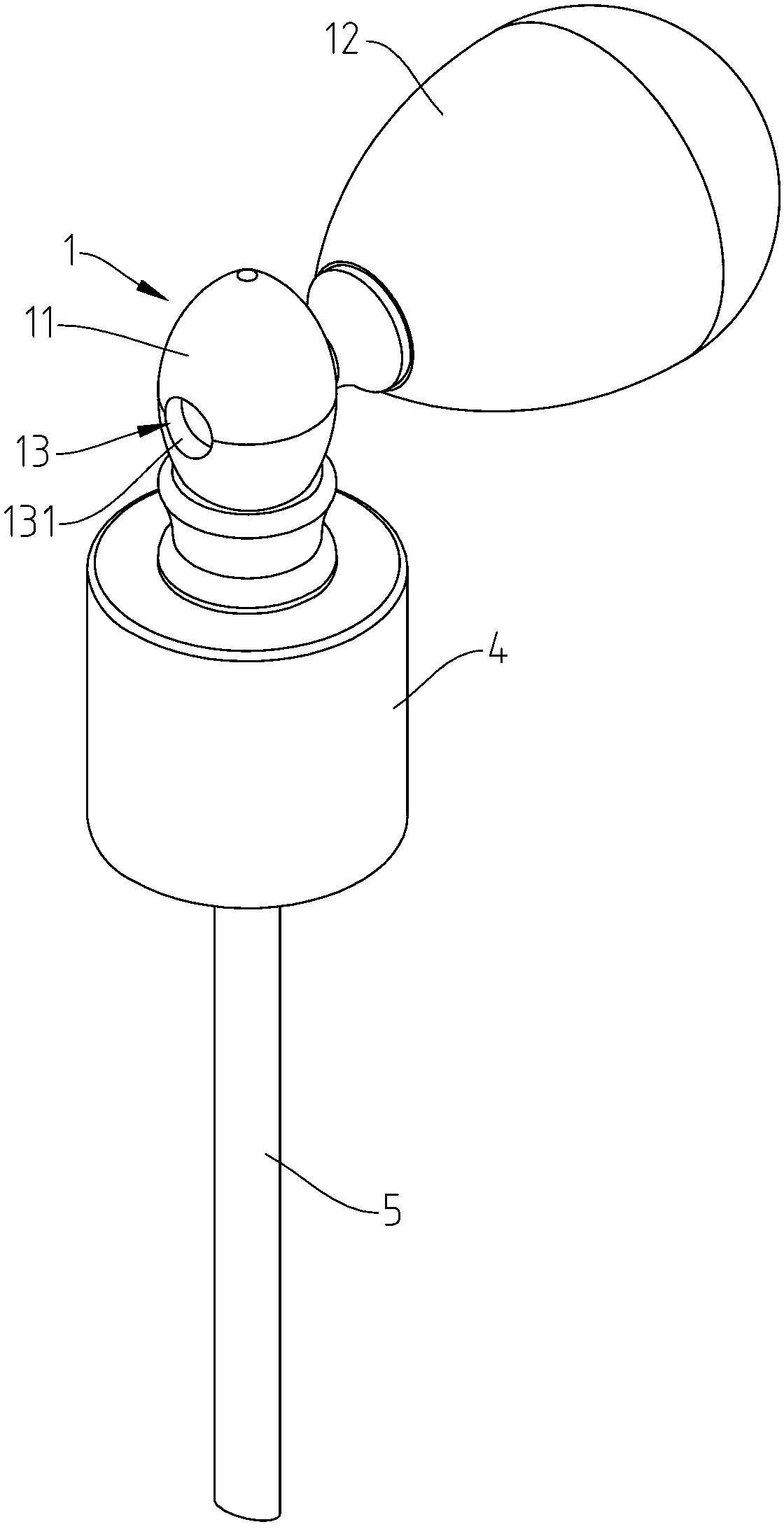

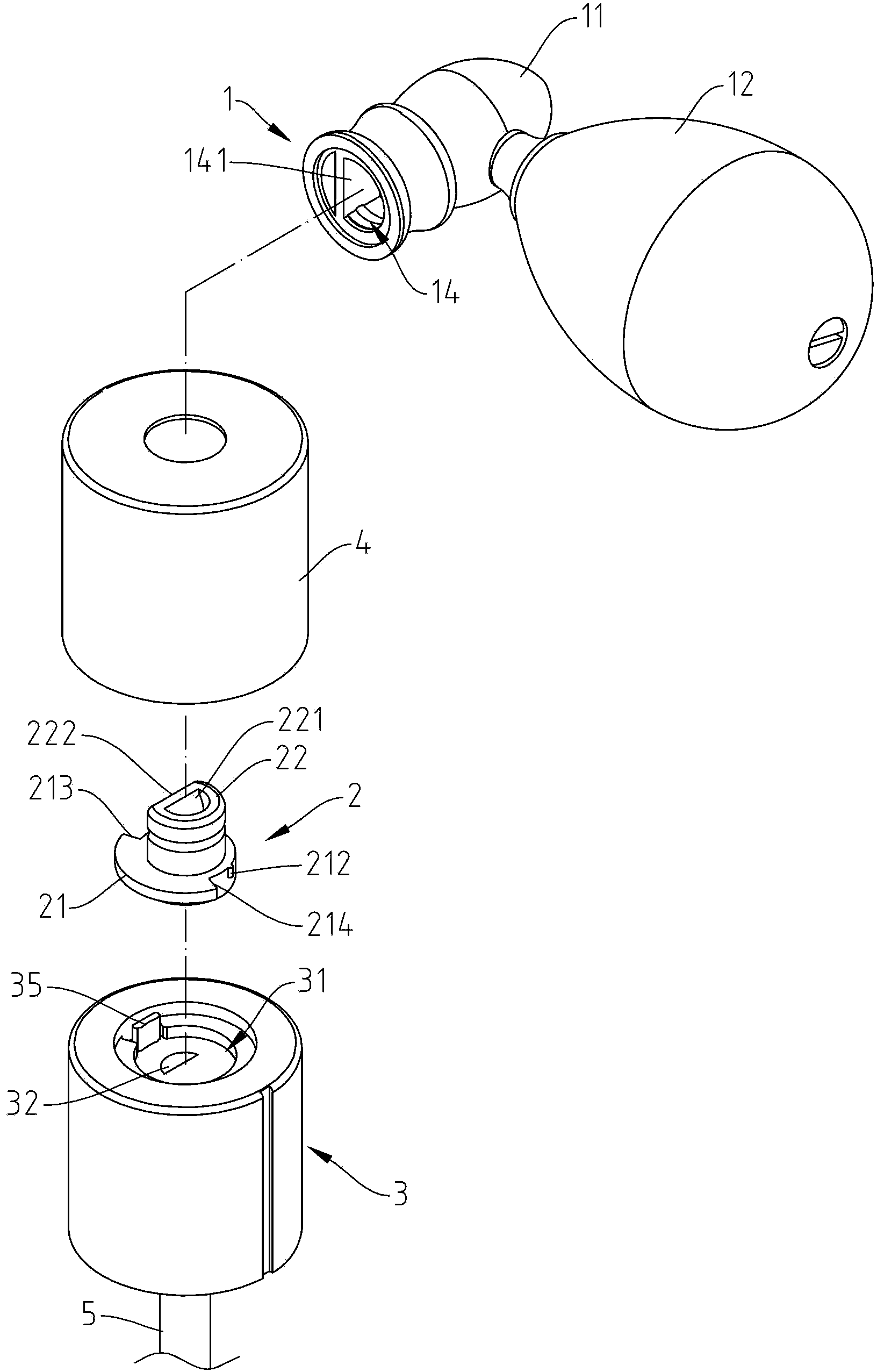

[0024] see Figure 1 to Figure 4 , the switch-type perfume spray head of the present invention includes a spray head group 1, a rotating part 2 and a docking seat 3, wherein:

[0025] The spray head group 1 has a spray head 11 and a pressure ball 12. The spray head 11 is pierced with a gas flow channel 13. One end of the gas flow channel 13 is connected to the pressure ball 12 to form a communication. There is a through hole 14 for communicating with the gas channel 13 , and the inner wall surface of the through hole 14 has a non-arc first limiting surface 141 .

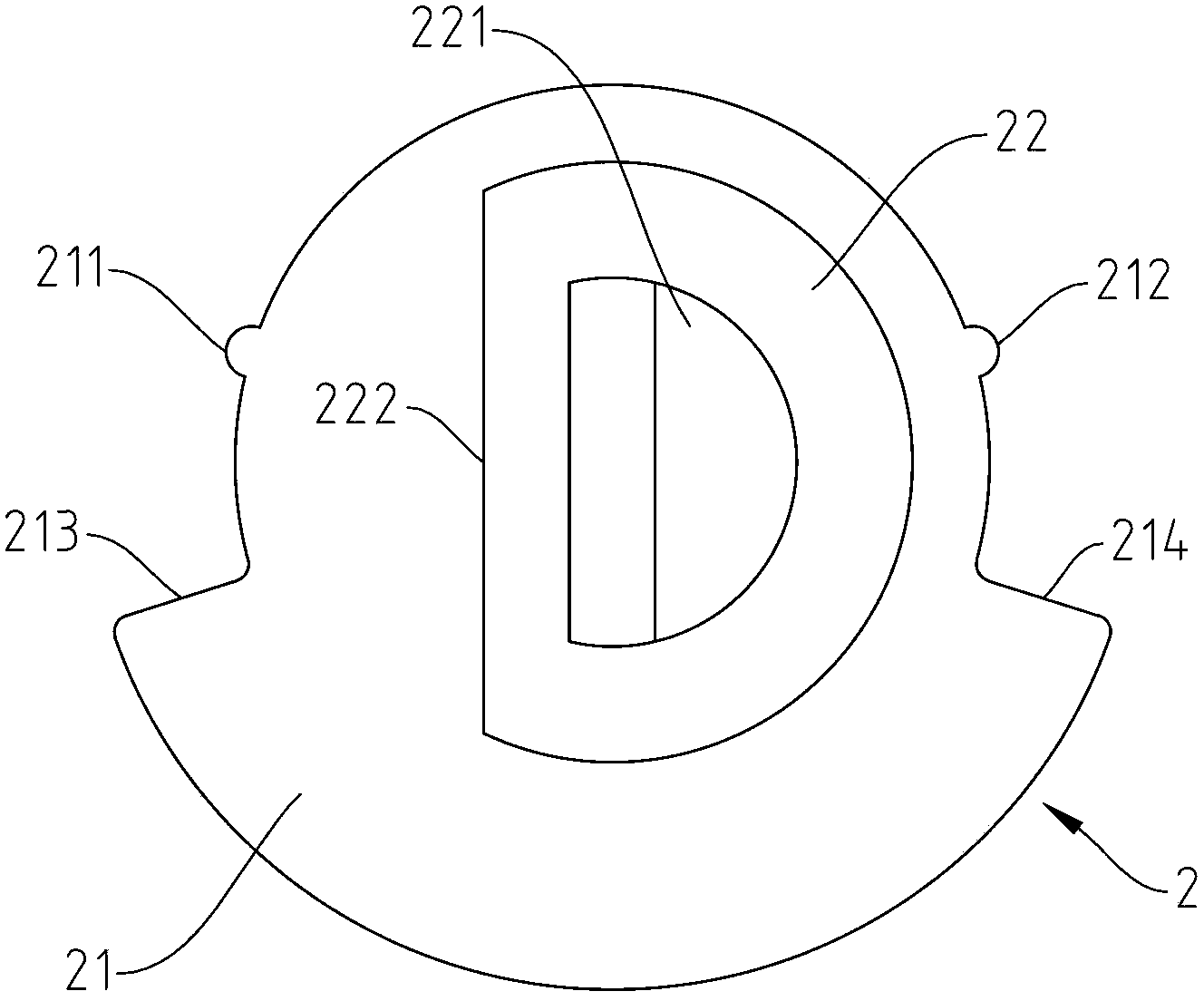

[0026] The rotating part 2 has a base 21 and a docking block 22, and the outer periphery of the base 21 is provided with a first locking part 211 and a second locking part 212 at intervals. The surface of one side of 212 is respectively provided with a first stop surface 213 and a second stop surface 214, the docking block 22 is extended from the base 21, and a first channel 221 is pierced in the docking block 22, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com