Self-cleaning type double-roller pill granulator

A cleaning roller and self-cleaning technology, which is applied in the direction of making medicines into special physical or ingestible devices, can solve the problems of the influence of the granulation process and the easy residue in the granulation space, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

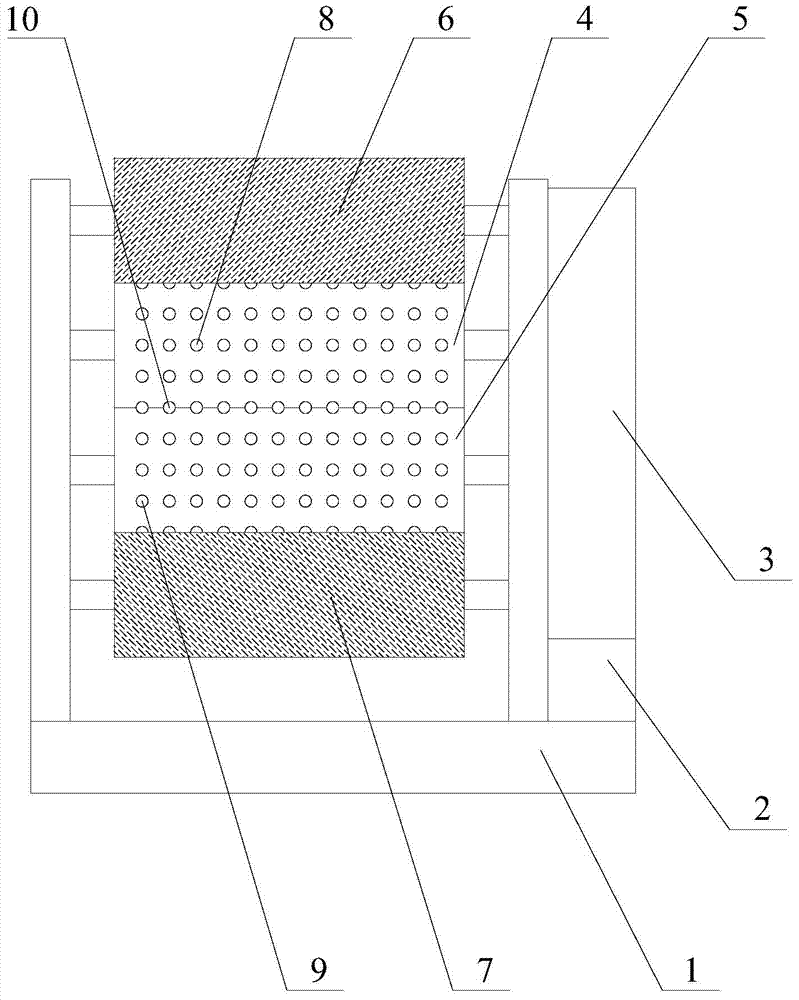

[0011] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a self-cleaning double-roller pill granulator proposed by the present invention.

[0012] refer to figure 1 , in one embodiment, a self-cleaning double-roller pill granulator proposed by the present invention includes a base 1, a power unit 2, a gear linkage mechanism 3, a first roller 4, a second roller 5, a first The cleaning roller 6, the second cleaning roller 7, the first cleaning roller 6, the first roller 4, the second roller 5, and the second cleaning roller 7 are arranged sequentially from top to bottom and are all supported by the base 1 and can be positioned relative to the base. 1 rotation, the power device 2 drives the first roller 4, the second roller 5, the first cleaning roller 6, and the second cleaning roller 7 through the gear linkage mechanism 3, and the first roller 4 is evenly opened and evenly arranged on the side of the first roller 4 The first semicircular groove 8 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com