Electronic board automatic spraying production line and production method

A technology of automatic spraying and production methods, applied in the direction of coating, spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of poor production environment, low production efficiency, and low degree of automation, so as to save time and improve production Efficiency and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

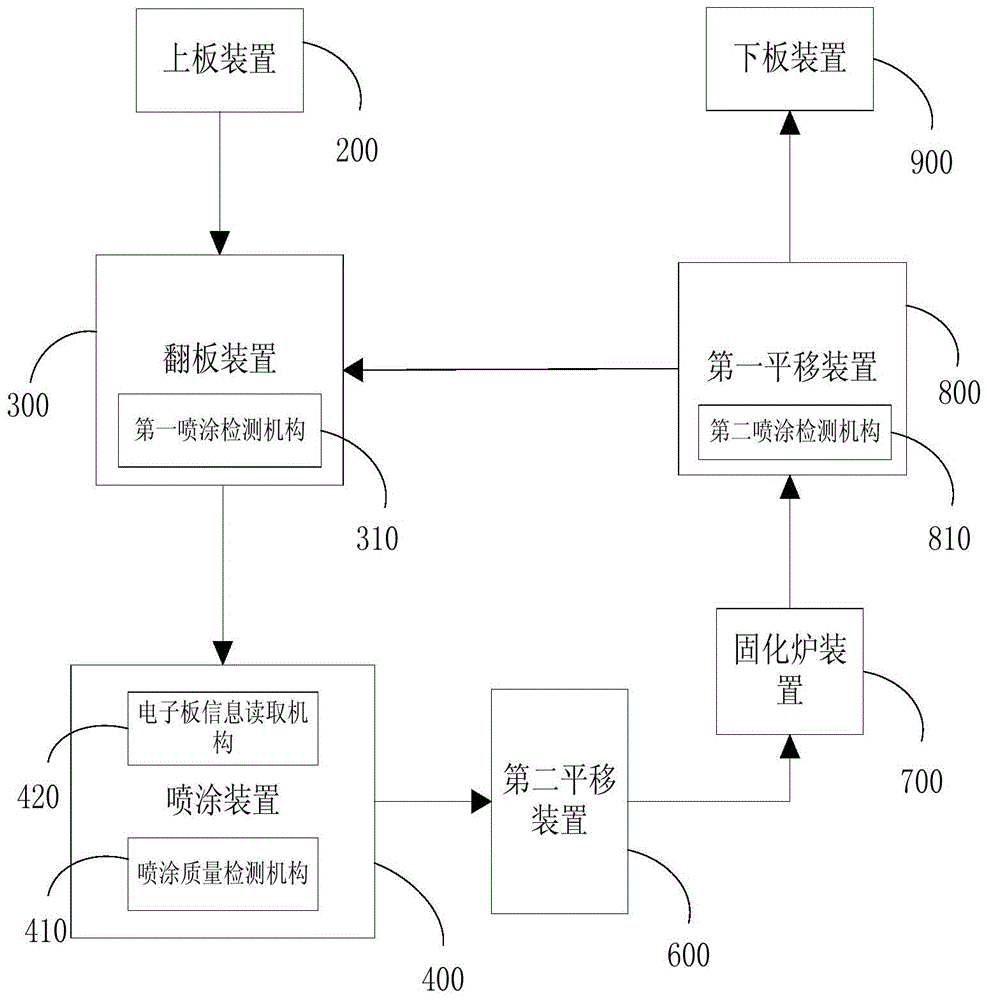

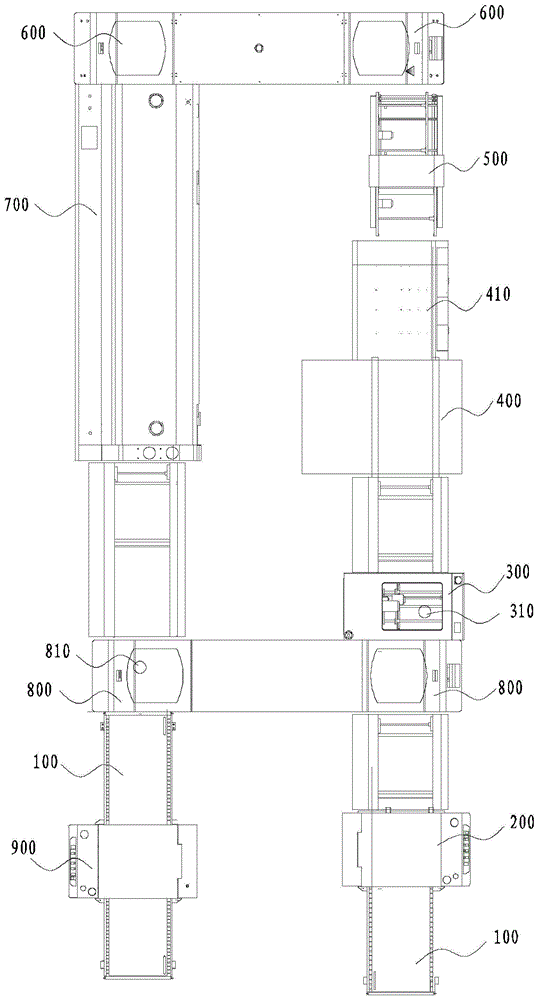

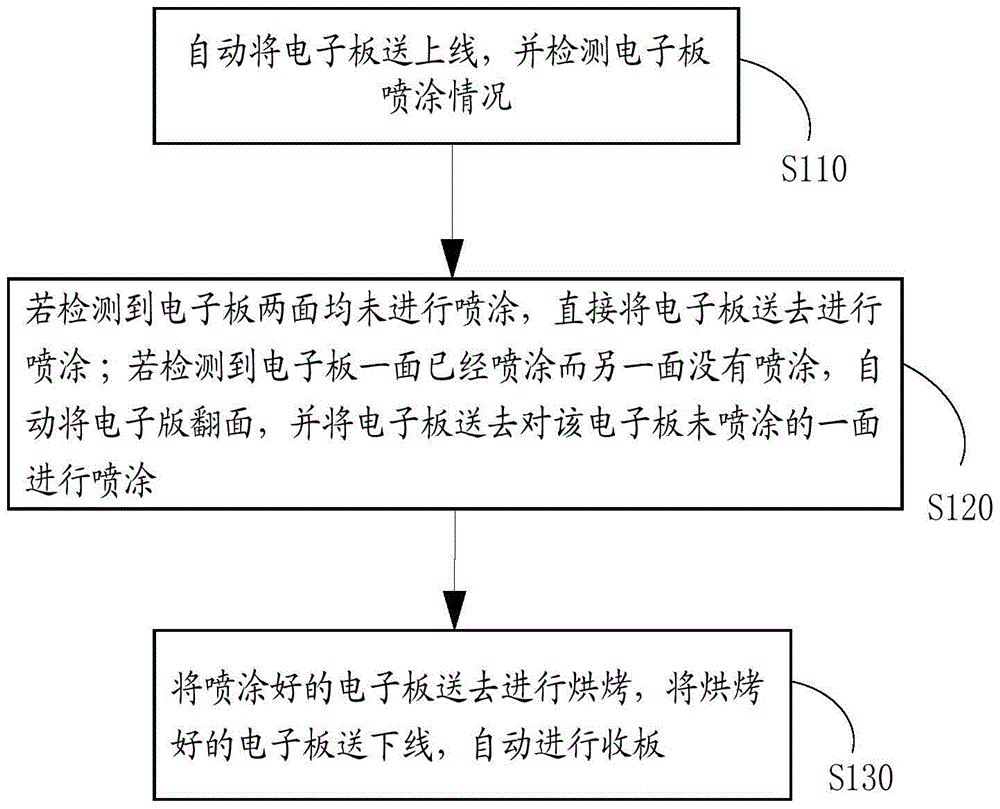

[0033] Such as Figure 1 to Figure 2 As shown, an electronic board automatic spraying production line includes a conveying mechanism 100, and an upper plate device 200, a plate turning device 300, a spraying device 400, a curing oven device 700 and a lower plate device 900 sequentially connected through the conveying mechanism 100. The board loading device 200 is arranged at the front end of the conveying mechanism 100 for automatic loading of electronic boards. The plate unloading device 900 is disposed at the end of the conveying mechanism 100 for automatically unloading the electronic board. The board turning device 300 is arranged between the board loading device 200 and the spraying device 400 for turning over the electronic board. Moreover, a first spraying detection mechanism 310 is installed on the panel turning device 300 for detecting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com