Machine for removing burrs in through hole of gear-shifting oscillating bar of transmission

A shift lever and burr removal technology, which is applied in filing/filing devices, filing/filing devices, metal processing equipment, etc., can solve the problems of poor product consistency, low efficiency, and affecting the installation of shift shafts, etc. , to achieve the effect of convenient operation, high degree of automation, improvement of production efficiency and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

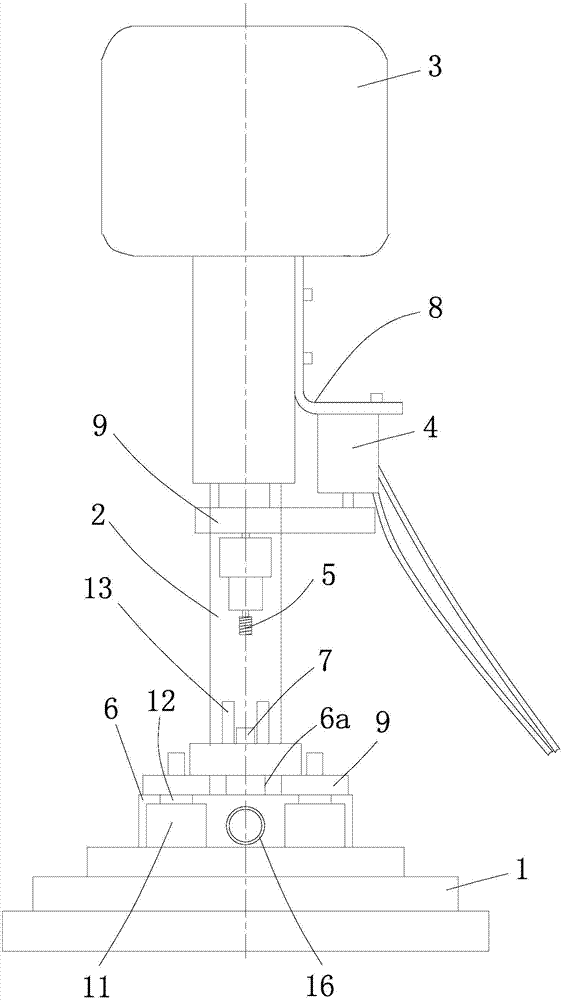

[0018] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

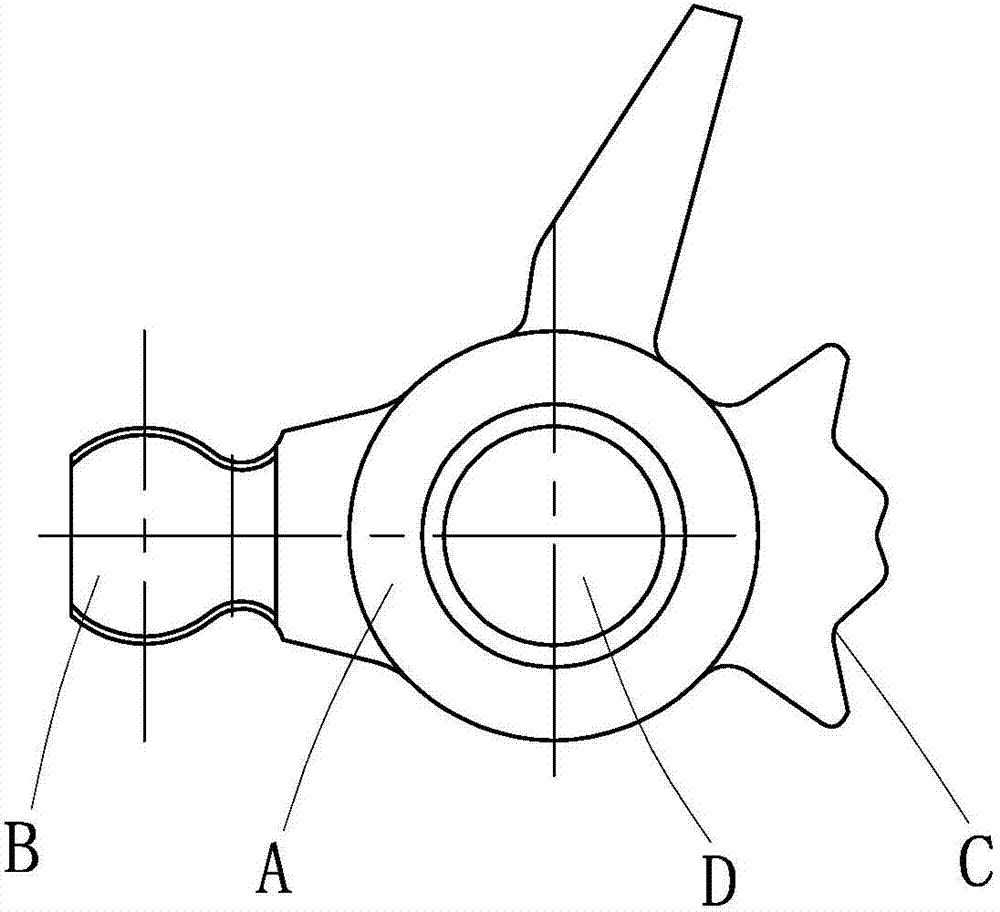

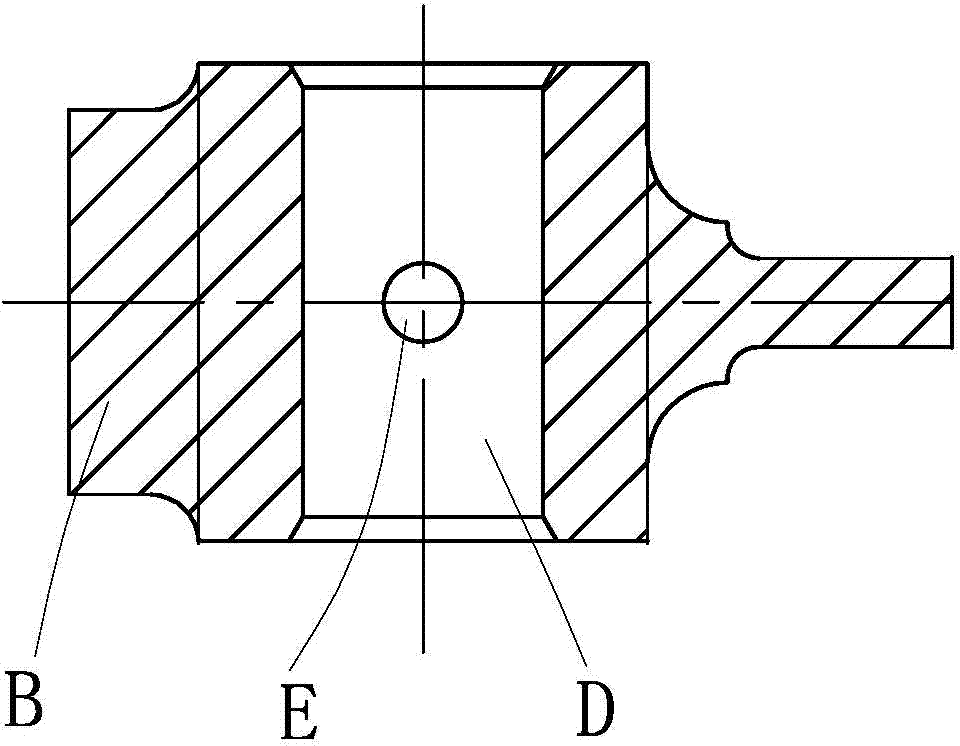

[0019] combine image 3 , Figure 4 As shown in the figure, a deburring machine in the through hole of the shift lever of the transmission is composed of a base 1, a support column 2, a drive motor 3, a drive cylinder 4 for advancing and retreating cutters, a carbide rotary file 5, a sliding support plate 6, and an automobile swing lever Sleeve column 7, mounting bracket 8, hoop plate 9, plastic tube 10, four bearings 11, four mounting shafts 12, two anti-rotation blocks for car swing rods 13, two limit plates 14, several outer hexagonal bolts 15 , manual fork 16 etc. are formed. In addition to the drive cylinder 4 for advancing and retreating the knife, the mounting bracket 8 and the hoop plate 9, the deburring machine has a left-right symmetrical structure.

[0020] The support column 2 is installed on the base 1, and the top of the support column 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com