Equipment for removing burr from inside of radial through hole of pipe fitting

A radial through hole and burr removal technology, applied in metal processing equipment, filing/filing device, filing/filing device, etc., can solve the problems of affecting parts installation, poor product consistency, low efficiency, etc. The effect of convenient operation, high degree of automation and extensive promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

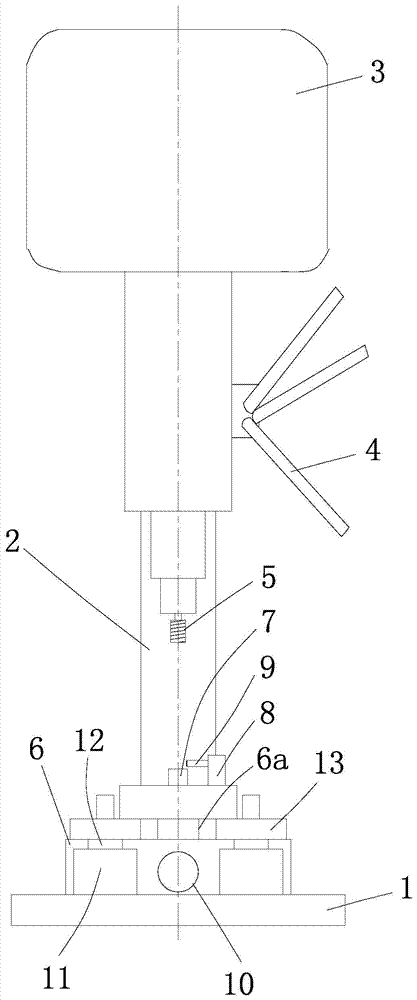

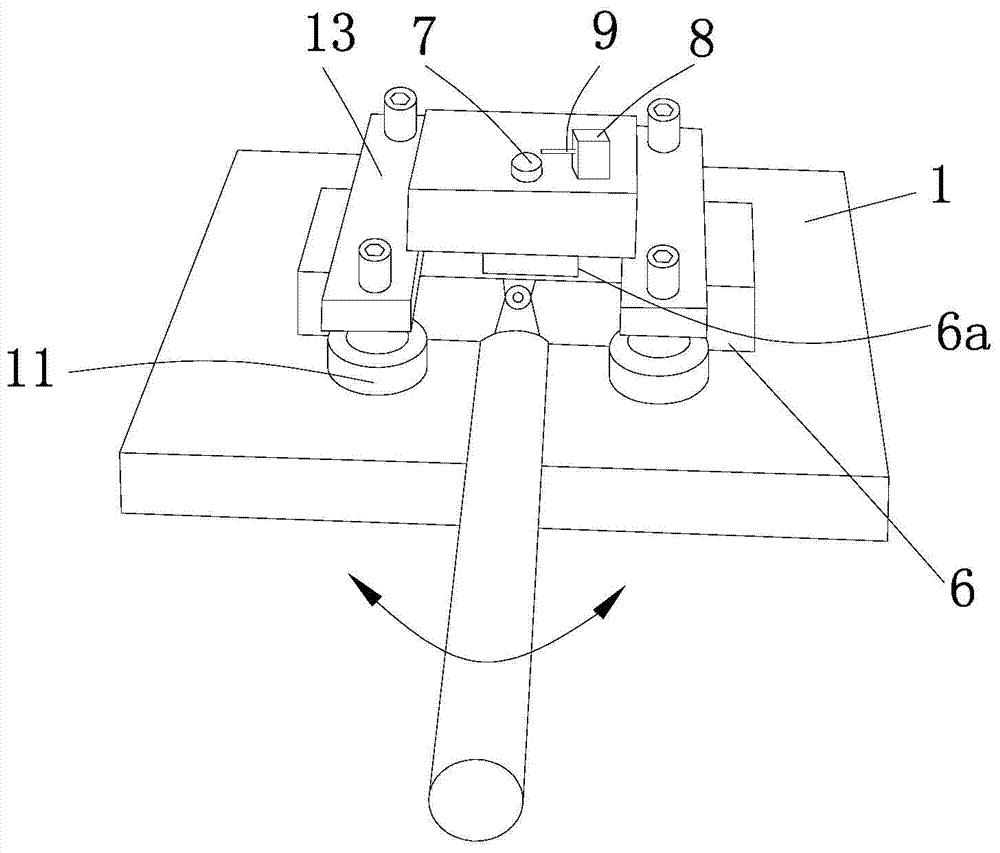

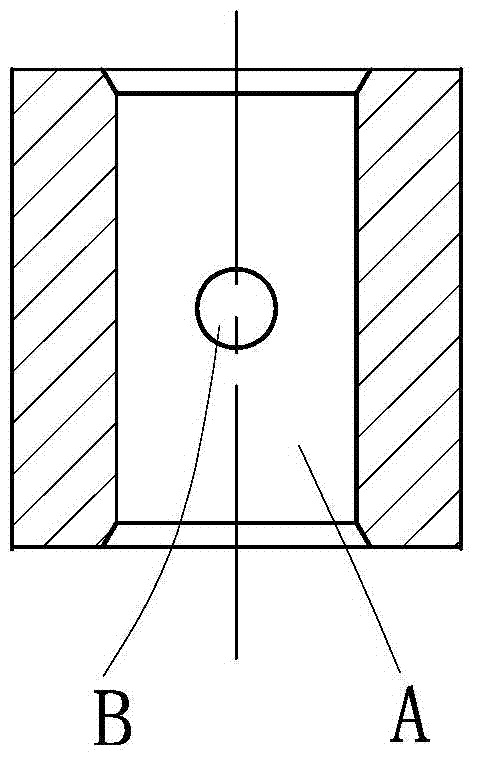

[0015] combine figure 1 , figure 2 As shown, a device for removing burrs in radial through holes in pipe fittings consists of a workbench 1, a support column 2, a drive motor 3, a manual turntable 4, a rotary file 5, a sliding pallet 6, a set cylinder 7, a horizontal cylinder 8, Anti-rotation ejector rod 9, manual fork 10, four bearings 11, four installation shafts 12, two limit plates 13 etc. are formed. In addition to the manual turntable 4, the horizontal cylinder 8, and the anti-rotation ejector rod 9, the deburring equipment has a left-right symmetrical structure.

[0016] The support column 2 is installed on the workbench 1, and the top of the support column 2 is provided with a machine head, which is composed of a drive motor 3, a manual turntable 4 and a rotary file 5. The drive motor 3 drives the rotary file 5 to rotate, and the manual turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com