Multi-point synchronous automatic pressing mechanism

A technology of synchronous automatic and pressing mechanism, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unsynchronized pressing, inability to adjust universality, poor safety, etc., and achieve safety and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

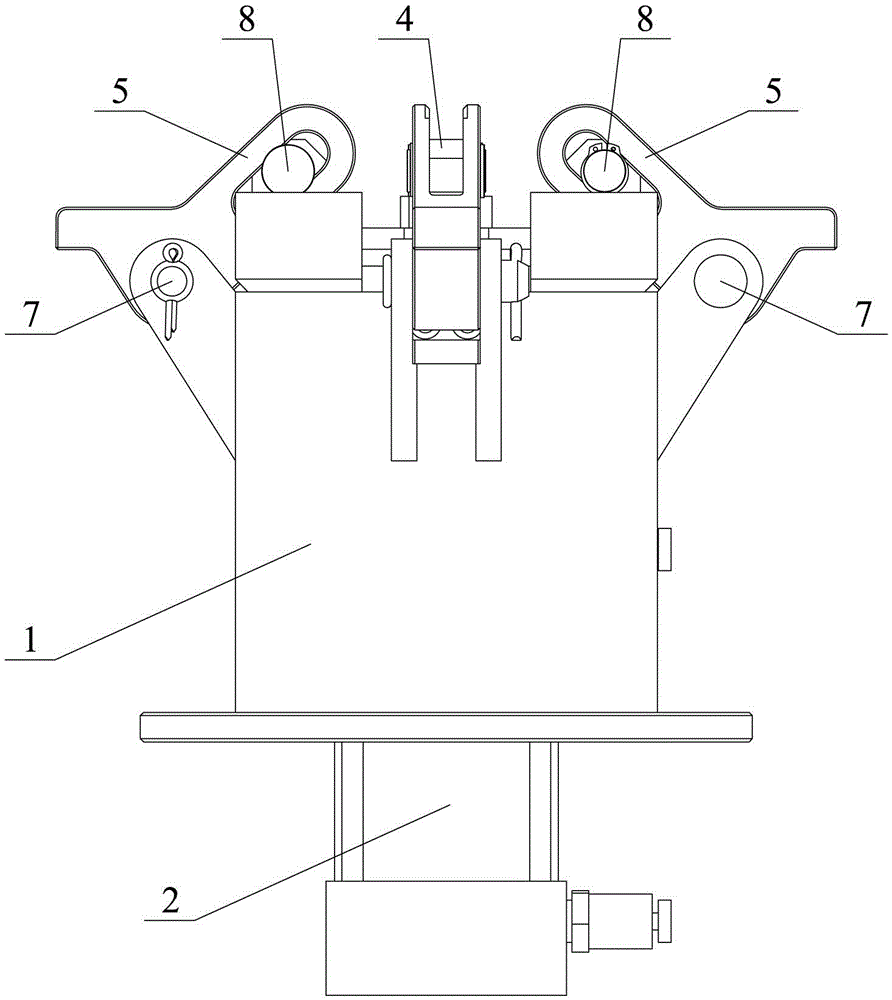

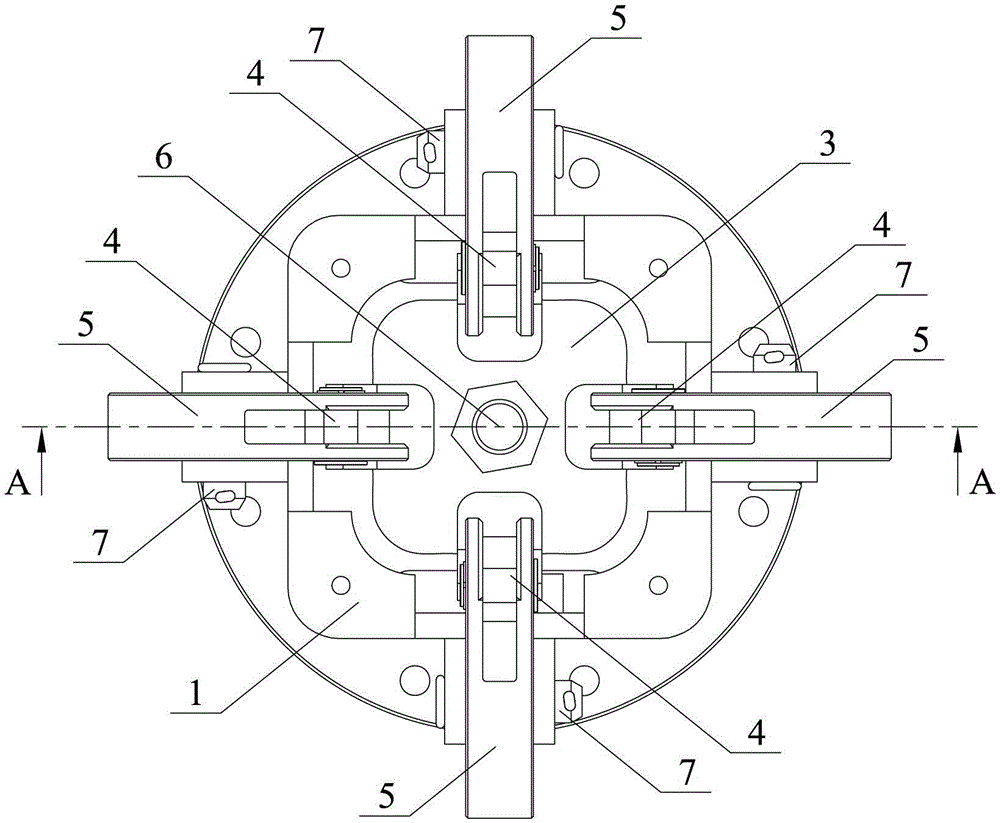

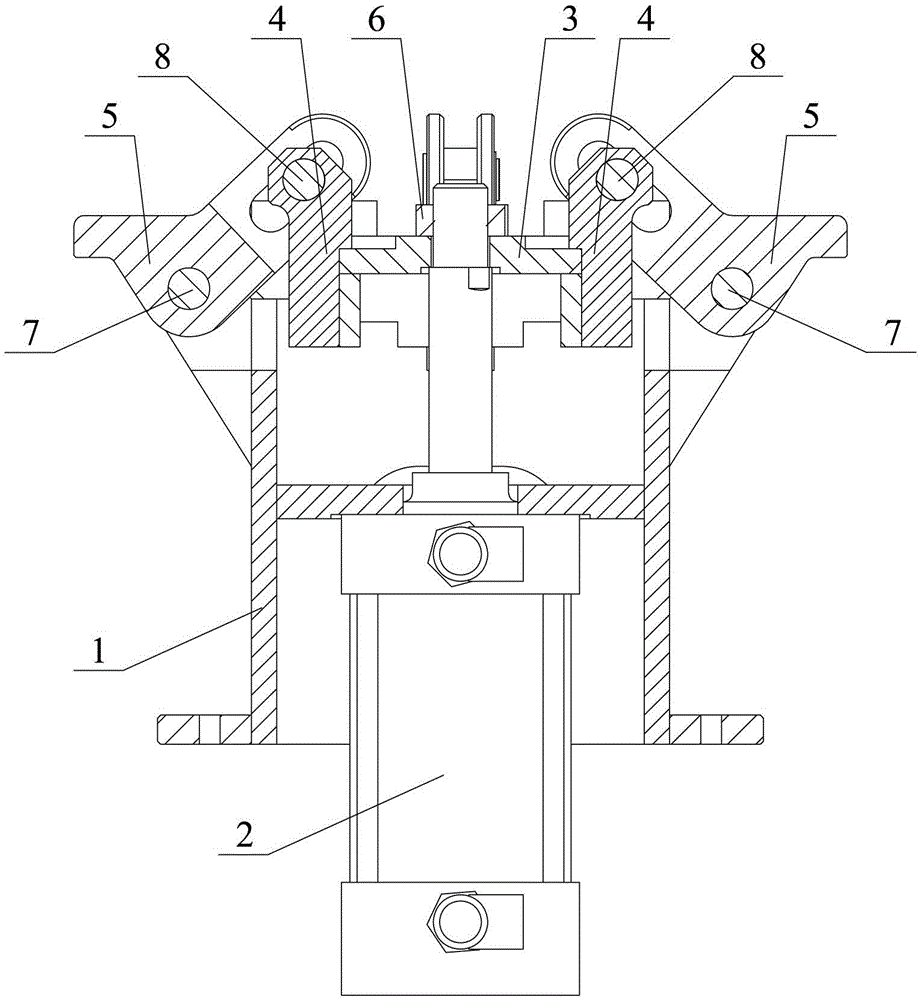

[0020] Embodiment one: see attached figure 1 to attach image 3 As shown, a multi-point synchronous automatic pressing mechanism includes a connecting seat 1, a cylinder 2, an intermediate connecting plate 3, a plurality of connecting blocks 4 and a plurality of pressing claws 5. The connecting seat 1 is cylindrical with a square cross-section, and a fixing plate is arranged in the middle thereof, and the cylinder body of the cylinder 2 is fixedly connected with the connecting seat 1 , specifically, the cylinder body is fixedly connected to the fixing plate of the connecting seat 1 . On the outer periphery of the connecting base 1 , that is, at the center of each plane on its outer surface, lifting lugs with pin holes are respectively provided. The middle connecting plate 3 is a square with rounded corners. It is fixedly connected to the piston of the cylinder 2 through the bump and the nut 6 arranged on the piston of the cylinder 2. The centers of the two overlap. When the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com