Novel full-automatic rotation anchoring device of gantry crane

A portal crane and slewing anchoring technology, which is applied to safety devices, transportation and packaging, load hanging components, etc., can solve the problems of not realizing fully automatic control of slewing anchoring devices and potential safety hazards, and achieve advanced design and liberation The effect of high productivity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

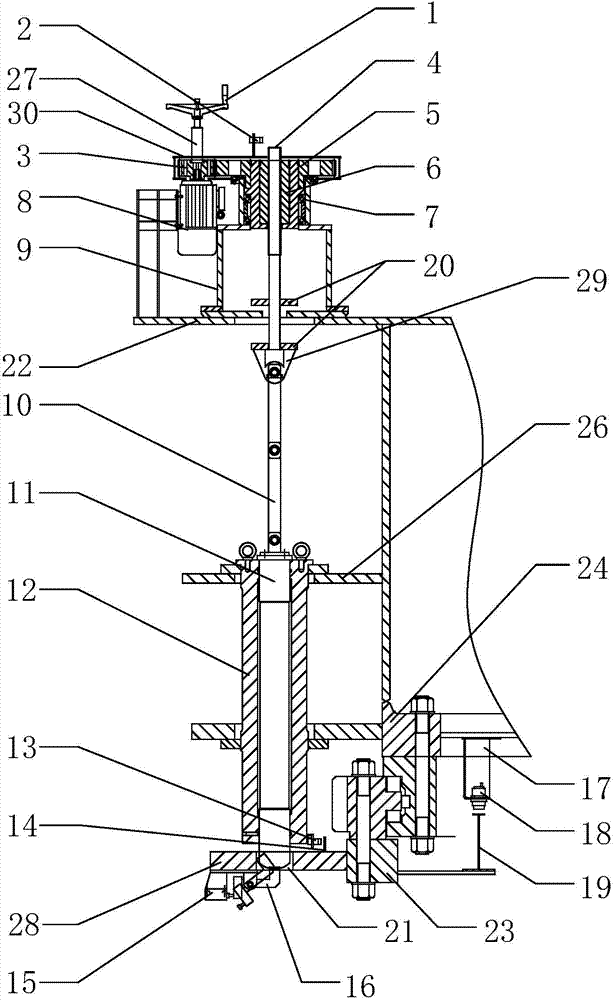

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

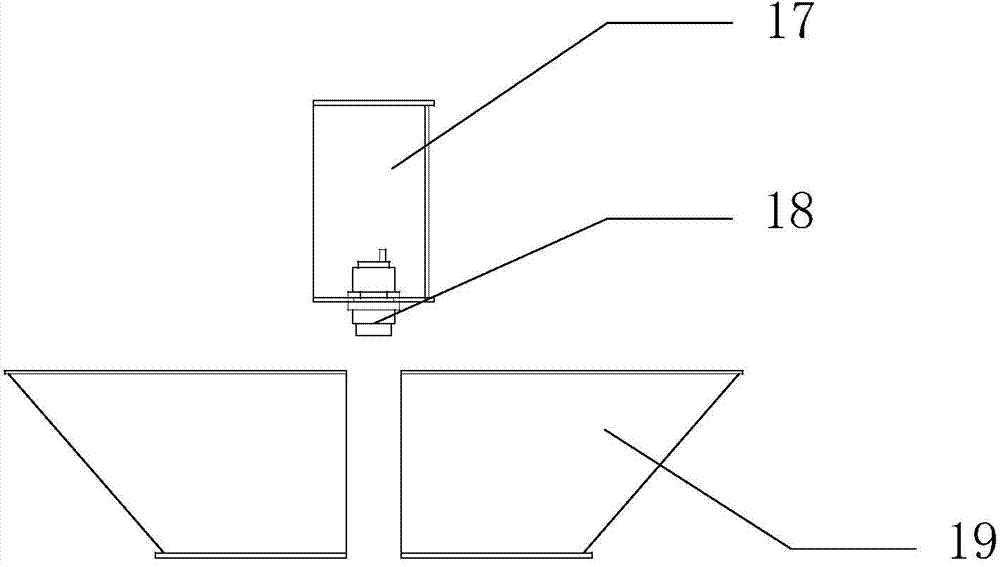

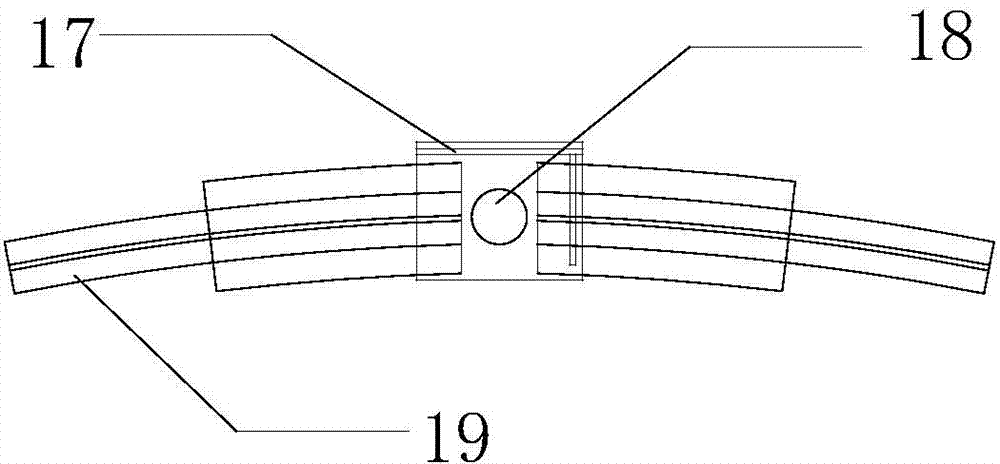

[0028] combine Figure 1 to Figure 7 , a new type of fully automatic rotary anchoring device for portal cranes, including a base 9 and an anchor pin plate 28, the bottom of the base 9 is fixedly connected with a support frame 22, and the right end of the support frame 22 is connected to the slewing platform 24 of the crane Fixed connection, the lower end of the slewing platform 24 is provided with a cylinder gantry 23 of a crane, the base 9 is a cavity structure, and a vertical transmission screw 4 is arranged inside the base 9, and a transmission large shaft is arranged on the upper part of the transmission screw 4. Gear 5, the transmission bull gear 5 meshes with the transmission pinion 3 on one side, and the lower end of the transmission pinion 3 is connected with the anchor reduction motor 8. The lower end of the transmission screw 4 stretches out from the support frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com