Preparation method and application of triazine anticoccidial medicinal composite molecularly imprinted polymer

A technology for imprinting polymers and composite molecules, which can be used in chemical instruments and methods, other chemical processes, etc., and can solve the problems of few preparation methods for molecularly imprinted solid-phase extraction columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Comparing methanol, acetonitrile, N, N-dimethylamide, tetrahydrofuran respectively, investigating the dissolving effects of different solvents on DIC, TOL and MAA, the results show that DIC and MAA are insoluble in methanol, insoluble in acetonitrile, slightly soluble N,N-dimethylamide and tetrahydrofuran, while TOL is insoluble in water, but soluble in the above four solvents, and is most soluble in tetrahydrofuran. Therefore, tetrahydrofuran can be selected as the primer for the preparation of DIC and TOL composite molecularly imprinted polymers. Pore agent. In this example, 0.204 g of DIC (0.5 mmol) and 0.213 g of TOL (0.5 mmol) were weighed and dissolved in 20 mL of tetrahydrofuran to obtain a tetrahydrofuran solution of composite template molecules.

[0022] (2) Compare the influence of functional monomer MAA and the ratio of template molecule I and II dosage: add functional monomer MAA in the tetrahydrofuran solution of the composite template molecule of ste...

Embodiment 2

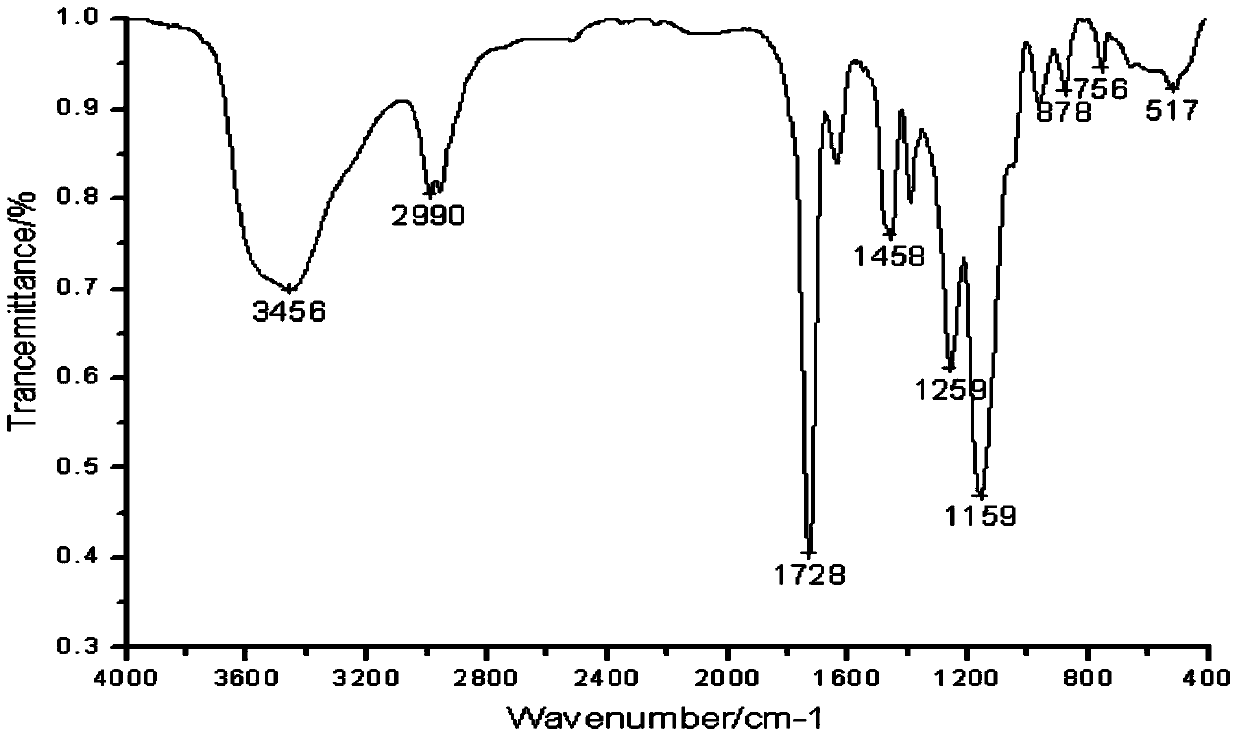

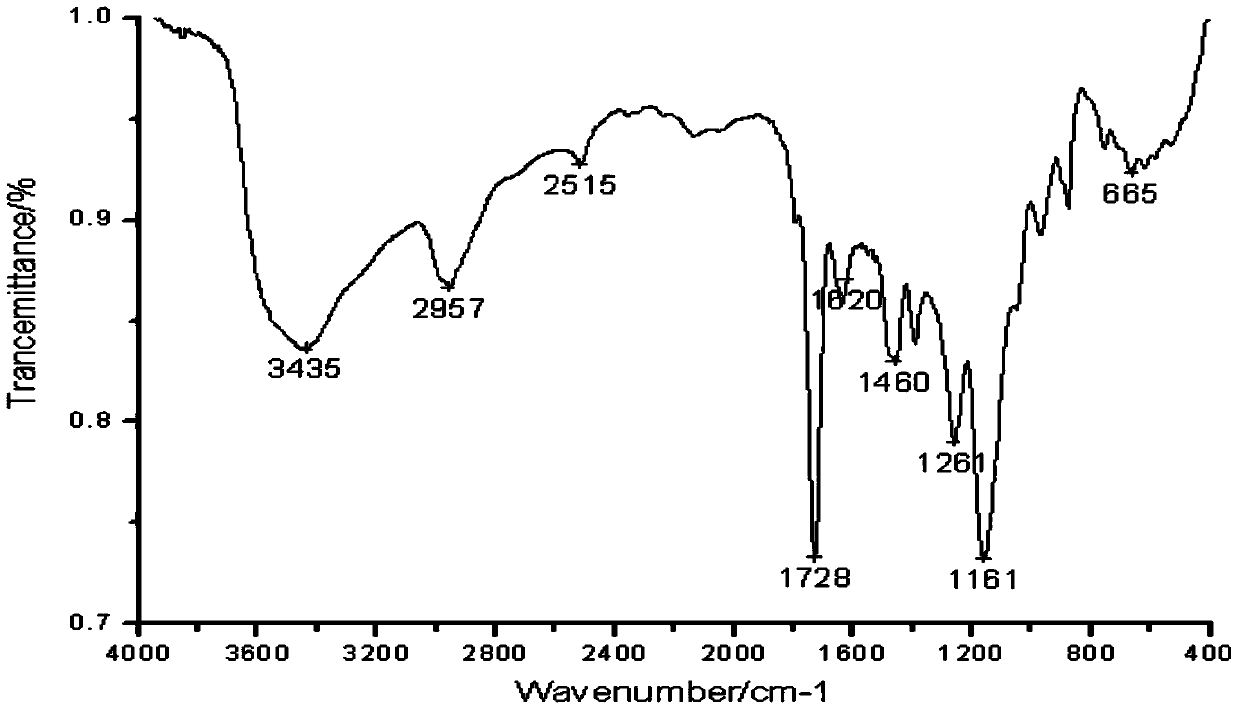

[0044] (1) Weigh no more than 0.204g of template molecule I diclazuril (DIC) and no more than 0.213g of template molecule II toltrazuril (TOL) and dissolve them in 20mL of tetrahydrofuran, add 0.336mL of functional monomer Methacrylic acid MAA, ultrasonically oscillating at room temperature for 30 minutes to fully combine template molecules I and II with functional monomers; then add 5.06mL of cross-linking agent PETA; then add 0.123g of azobisisobutyronitrile AIBN, mix well , ultrasonic oscillation for 15min, at N 2 Heat in a 60°C water bath for 16 hours under protection to obtain a white solid polymer;

[0045] (2) Pulverize the white solid polymer in step (1), grind it through a 200-mesh sieve, and elute the template molecules (DIC&TOL) in the polymer with a volume ratio of 6:3:1 acetonitrile / water / acetic acid solution, collect The product was dried in an oven at 60°C to obtain molecularly imprinted polymers (DIC&TOL MIPs) using DIC and TOL as composite templates.

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com