A kind of preparation method and application of soft high-solid aqueous polyurethane resin

A polyurethane resin and water-containing technology, which is applied in the direction of improved hand-feeling fibers, etc., can solve the problems of increasing the cost and high price of high-solid water-containing polyurethane resin, and achieve the effects of high cost performance, soft film formation and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

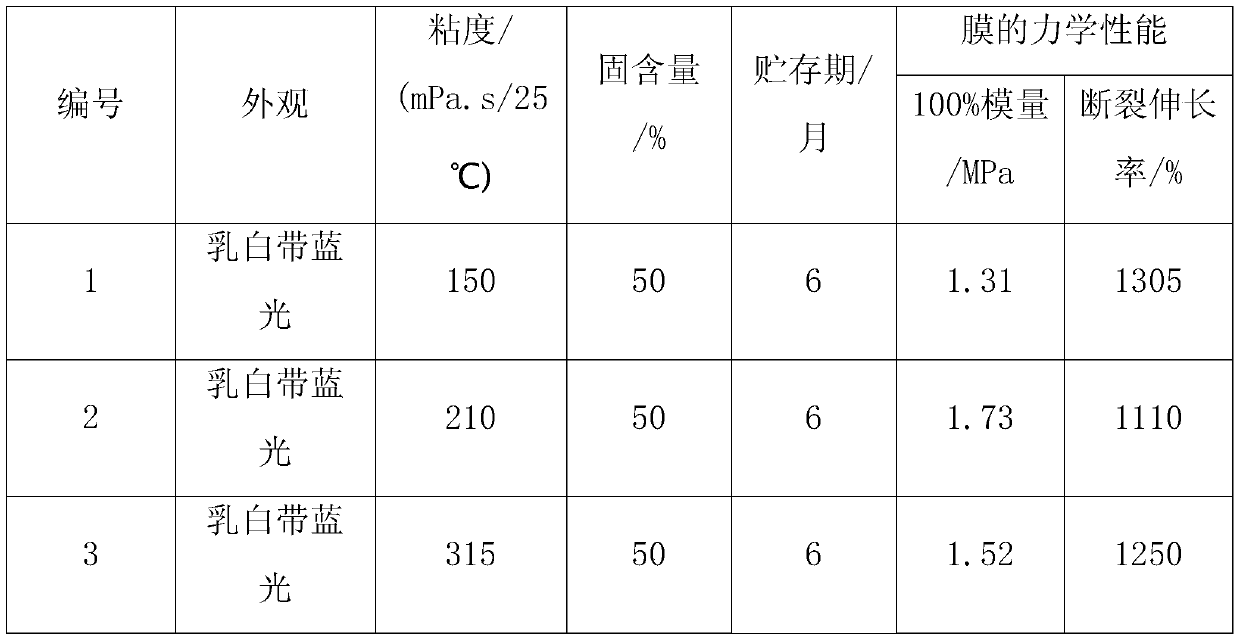

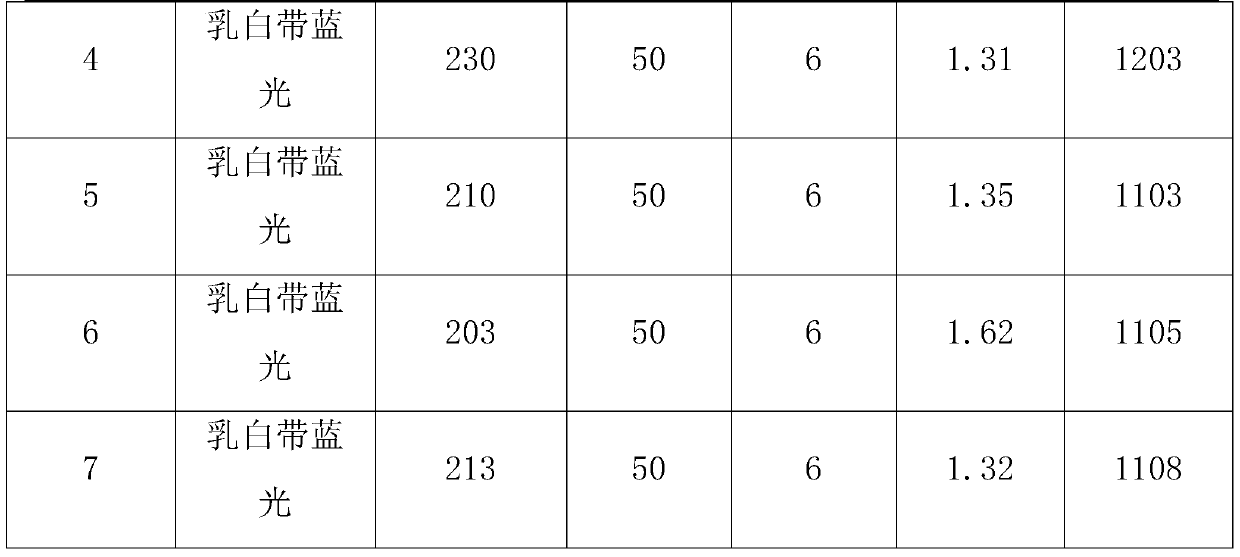

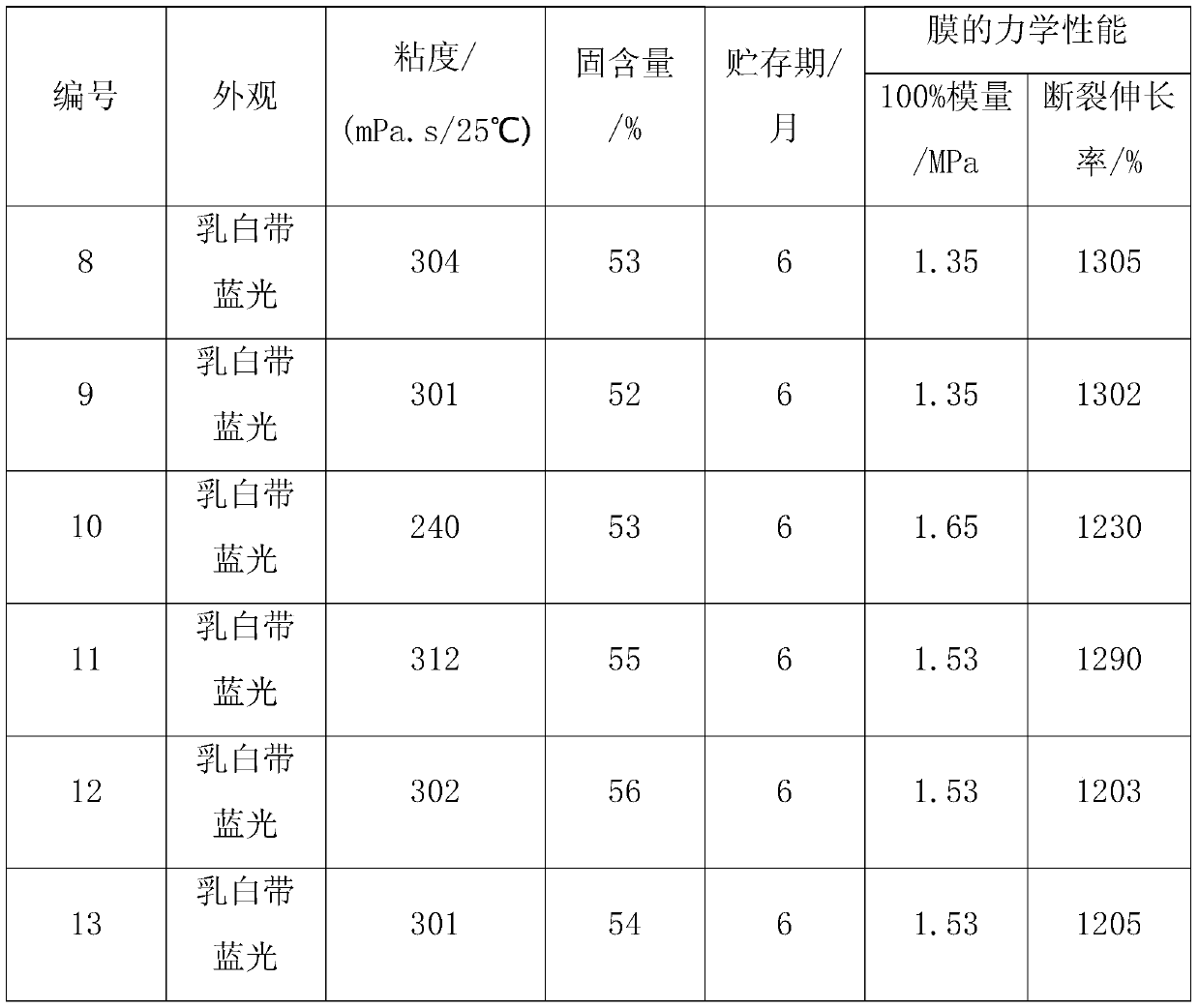

Examples

Embodiment 1

[0048] Embodiment 1 A kind of preparation method of soft high-solid aqueous polyurethane resin

[0049] The preparation method of high-solid aqueous polyurethane resin, the steps are as follows:

[0050] 200g of polyfumaric acid-adipate-diethylene glycol ester polyol containing at least one sodium sulfonate group and a molecular weight of 2000 in the main chain and 1400g of polyadipate-1,4-polyol with a molecular weight of 2000 The butanediol ester diol is put into the reaction kettle, heated and melted by heating and stirred evenly. Dehydration under reduced pressure at 120° C. and a vacuum degree of 0.1 MPa for 1 hour. After the dehydration is completed, lower the temperature to 60°C, add 200g of acetone, stir evenly, add 260g of toluene diisocyanate (TDI), raise the temperature to 80°C and react for 2 hours to obtain a polyurethane prepolymer.

[0051] Subsequently, 40 g of ethylene glycol was added to continue the reaction for 2 hours. If the measured NCO% was less than ...

Embodiment 2

[0053] Embodiment 2 A kind of preparation method of soft high-solid aqueous polyurethane resin

[0054] The preparation method of high-solid aqueous polyurethane resin, the steps are as follows:

[0055] 220g of polyfumaric acid-adipate-diethylene glycol ester polyol with a molecular weight of 2000 and 1400g of polyadipate-neopentyl glycol ester glycol with a molecular weight of 2000 are put into the reactor, heated and melted and stir well. Dehydration under reduced pressure at 120° C. and a vacuum degree of 0.1 MPa for 1 hour. After the dehydration is completed, lower the temperature to 60°C, add 200g of acetone, stir evenly, add 278g of toluene diisocyanate (TDI), raise the temperature to 80°C and react for 2 hours to obtain a polyurethane prepolymer.

[0056] Subsequently, 60 g of 1,6-hexanediol was added to continue the reaction for 2 hours. If the measured NCO% was less than or equal to 1.2%, the reaction was terminated. Add 2000g of acetone dropwise to the reactant t...

Embodiment 3

[0058] Embodiment 3 A kind of preparation method of high solid aqueous polyurethane resin

[0059] The preparation method of high-solid aqueous polyurethane resin, the steps are as follows:

[0060] The 300g main chain contains at least one sodium sulfonate group, the polyfumaric acid-adipic acid-ethylene glycol-diethylene glycol polyol of 3000 molecular weight and the polytetrahydrofuran ether glycol of 2000 with a molecular weight of 1500g are dropped into In the reaction kettle, heat up to melt and stir evenly. Dehydration was carried out under reduced pressure at 120° C. and a vacuum degree of 0.1 MPa for 1 hour. After the dehydration is completed, lower the temperature to 60°C, add 200g of acetone, stir evenly, add 280.5g of toluene diisocyanate (TDI), raise the temperature to 80°C and react for 2 hours to obtain a polyurethane prepolymer.

[0061] Subsequently, 30 g of ethylene glycol was added to continue the reaction for 2 hours. If the measured NCO% was less than or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com