Ellipse-arc compound cycloidal rotor oil pump and its rotor and rotor design method

An elliptical arc and circular arc technology, applied in the design of rotors, ellipse-circular arc compound cycloid rotor oil pump and its rotor field, can solve the problems of normal meshing transmission, speed fluctuation, affecting work efficiency and quality of life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

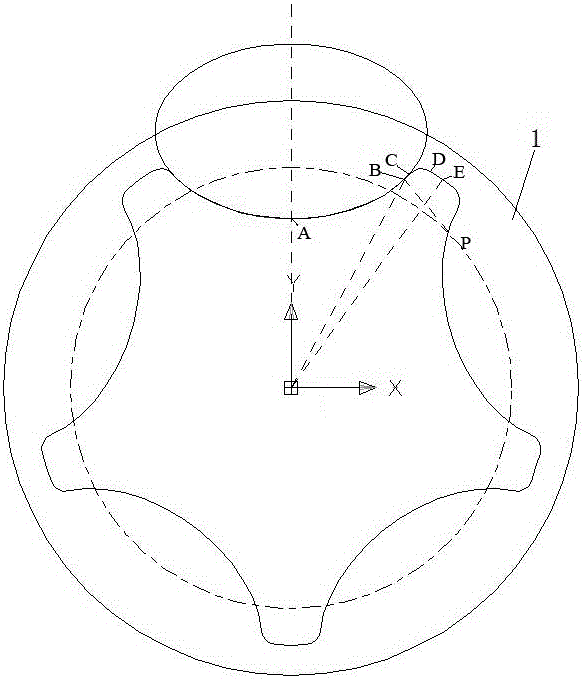

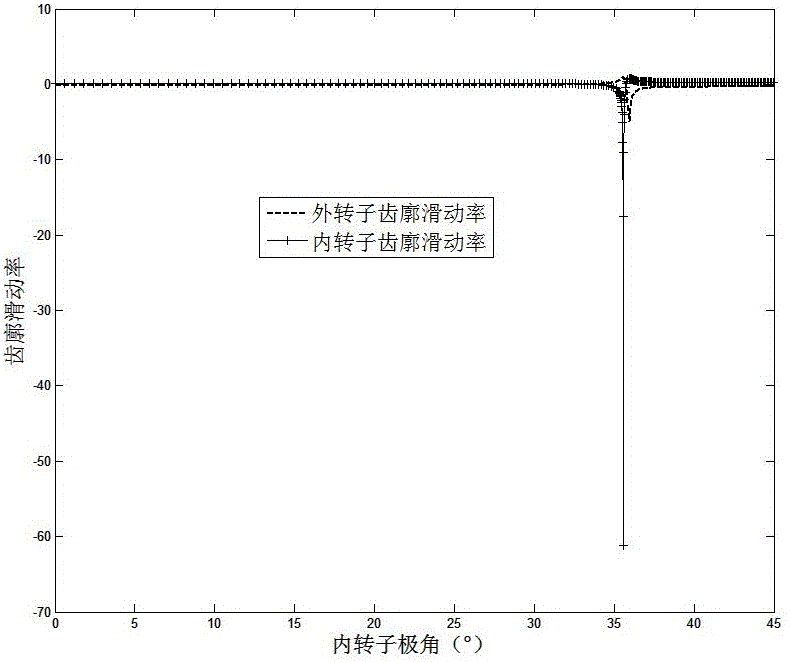

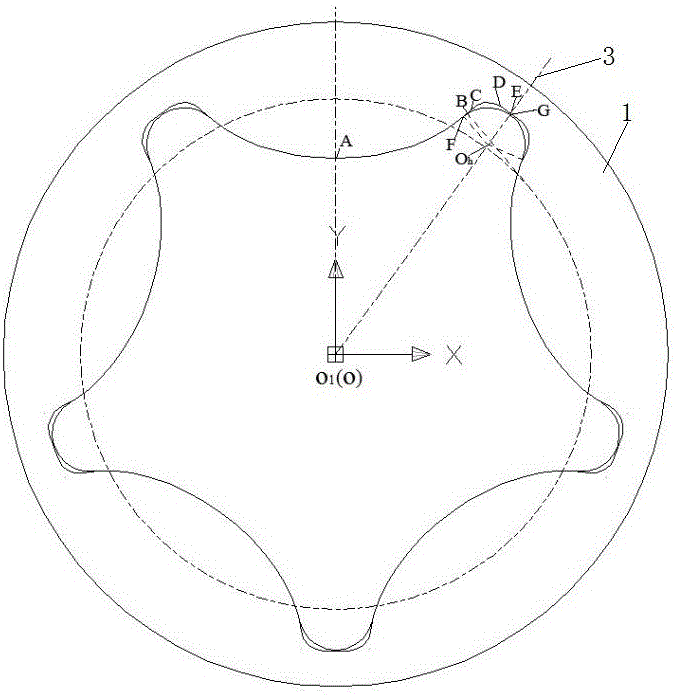

[0055] like Figure 3-7 As shown, a design method of an ellipse-arc composite cycloidal rotor includes the following steps:

[0056] Step (1), determine the relationship between the rotor meshing gap Δ and the compound point F of the ellipse-arc;

[0057] Design an elliptical arc from the tooth apex A to the meshing boundary point B on the outer rotor tooth profile of the existing elliptical arc cycloidal oil pump rotor of the same size, and select any point F on this elliptical arc as an ellipse-circular arc compound point, then the tooth profile length between the ellipse-arc compound point F and the meshing boundary point B of the outer rotor elliptical arc segment is make is the arc length from the tooth top vertex A to the meshing boundary point B The arc length from the addendum vertex A to the compound point F of the ellipse-arc difference, that is

[0058] The parametric equation of the elliptical arc section of the outer rotor of the ellipse-arc compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com