Elliptic-circular compound cycloid rotor oil pump, rotor thereof and rotor design method

An elliptical arc and circular arc technology, which is applied in the design field of elliptical-arc compound cycloidal rotor oil pump and its rotor and rotor, can solve the problems of severe wear, inattention, reduction, etc. in the meshing process of the inner and outer rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

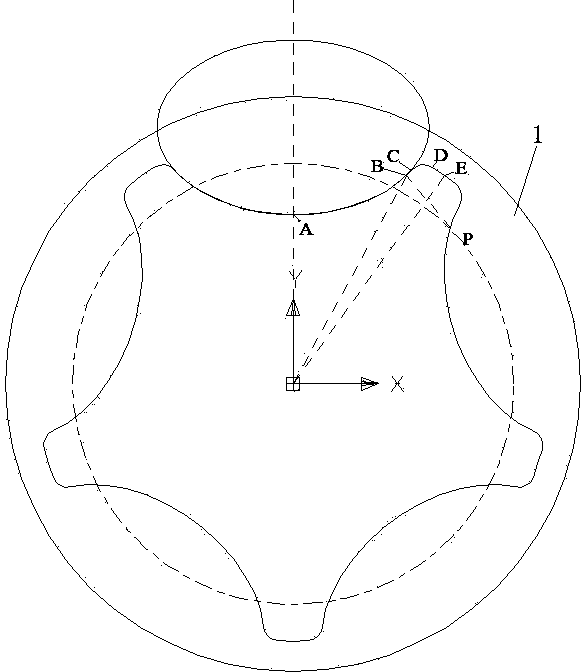

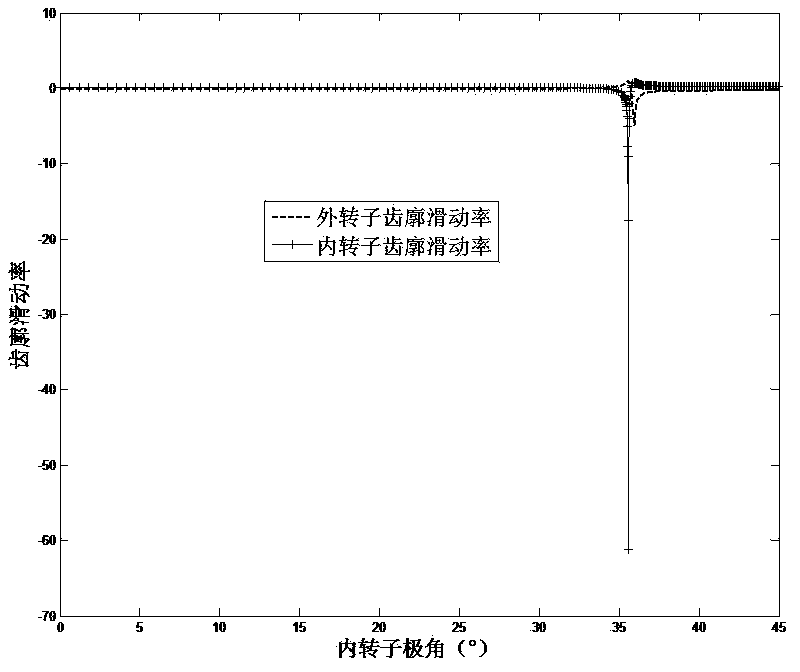

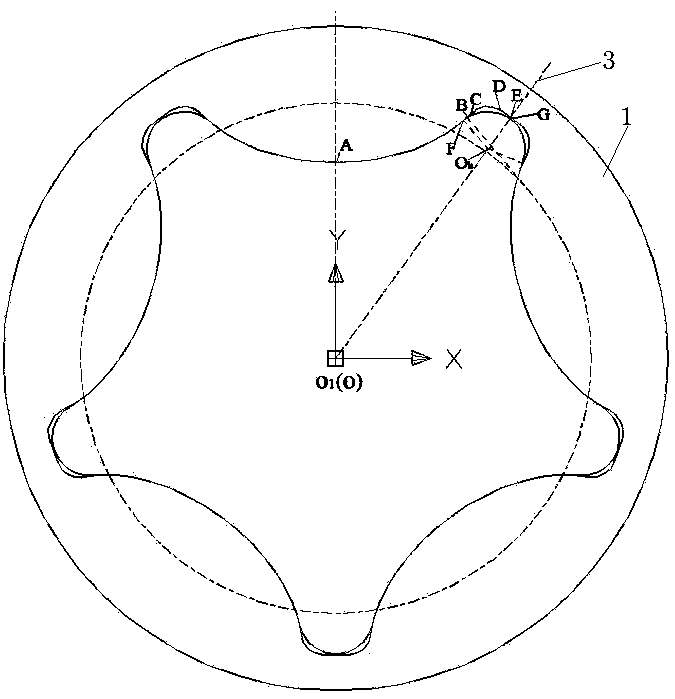

[0055] Such as Figure 3-7 As shown, a design method of an ellipse-arc composite cycloidal rotor includes the following steps:

[0056] Step (1), determine the relationship between the rotor meshing gap Δ and the compound point F of the ellipse-arc;

[0057] Design an elliptical arc from the tooth apex A to the meshing boundary point B on the outer rotor tooth profile of the existing elliptical arc cycloidal oil pump rotor of the same size, and select any point F on this elliptical arc as an ellipse-circular arc compound point, then the tooth profile length between the ellipse-arc compound point F and the meshing boundary point B of the outer rotor elliptical arc segment is make is the arc length from the tooth top vertex A to the meshing boundary point B The arc length from the addendum vertex A to the compound point F of the ellipse-arc difference, that is

[0058] The parametric equation of the elliptical arc section of the outer rotor of the ellipse-arc compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com