Battery charging method for electric road vehicle

A technology for road vehicles and charging methods, applied to secondary battery charging/discharging, batteries, circuits, etc., can solve the problems of uncontrollable battery charging process, reduce gas precipitation overpotential, electrolytic water gas evolution, etc., to reduce heat loss Water, reduced charging time, reduced effects of sulfation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] [Example 1] Charging method of 3EVF200 (8 pieces / set of 24 single storage batteries) battery pack in an environment of 25°C

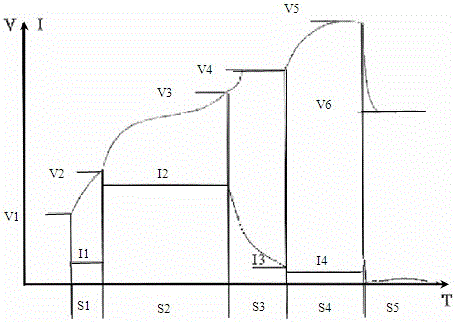

[0063] Step 1. Pre-charging: The battery pack is charged with a corresponding current of 3.5A, and its voltage is gradually increased to 48V, and its charging time is ≤3h;

[0064] Step 2. Constant current charging: the battery pack is charged with a corresponding current of 30A, the charging voltage is gradually increased to 57.6V, and the total charging time is ≤6h;

[0065] Step 3. Double-limit charging: When charging with a maximum current of 30A to 57.6V, the charging current gradually decreases, the voltage of the battery pack slowly rises to 58.8V, and when the charging current gradually decreases to 3.5A, transfer to the next step of charging. The total charging time ≤2h;

[0066] Step 4. Trickle charging: the trickle charging current is 3.5A, and the charging time is ≤1h;

[0067] Step 5. Float charging: the voltage limit is 55.4V, the...

Embodiment 2

[0069] [Example 2] Charging method of 3EVF200 (8 pieces / set of 24 single storage batteries) battery pack in an environment of 40°C

[0070] Step 1. Pre-charging: The battery pack is charged with a corresponding current of 3.5A, and its voltage is gradually increased to 48V, and its charging time is ≤3h;

[0071] Step 2. Constant current charging: the battery pack is charged with a corresponding current of 30A, the charging voltage is gradually increased to 57.6V, and the total charging time is ≤6h;

[0072] Step 3. Double-limit charging: When charging with a maximum current of 30A to 57.6V, the charging current gradually decreases, the voltage of the battery pack slowly rises to 57.7V, and when the charging current gradually decreases to 3.5A, transfer to the next step of charging. The total charging time ≤2h;

[0073] Step 4. Trickle charging: trickle charging current 3.5A, charging ≤ 1h;

[0074] Step 5. Float charging: limit voltage to 54V, limit current to 2.7A and charg...

Embodiment 3

[0077] [Example 3] Charging method of 3EVF200 (8 pieces / set of 24 single storage batteries) battery pack in -15°C environment

[0078] Step 1. Pre-charging: The battery pack is charged with a corresponding current of 3.5A, and its voltage is gradually increased to 48V, and its charging time is ≤2h;

[0079] Step 2. Constant current charging: the battery pack is charged with a corresponding current of 30A, the charging voltage is gradually increased to 57.6V, and the total charging time is ≤6h;

[0080] Step 3. Double-limit charging: When charging with a maximum current of 30A to 57.6V, the charging current begins to drop, the voltage of the battery pack slowly rises to 61.6V, and when the charging current gradually decreases to 3.5A, it is transferred to the next step of charging. The total charging time ≤2h;

[0081] Step 4. Trickle charging: trickle charging current 3.5A, charging time ≤ 1h;

[0082] Step 5. Float charge: charge with a voltage limit of 59.2V and a current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com