A connector socket

A connector and female seat technology, which is applied in the directions of connection, connection component installation, connection device components, etc., can solve the problems of complex structure of connector female seat and inconvenient connection, and achieve compact and ingenious structure, convenient connection and installation, The effect of the connection is easy to clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

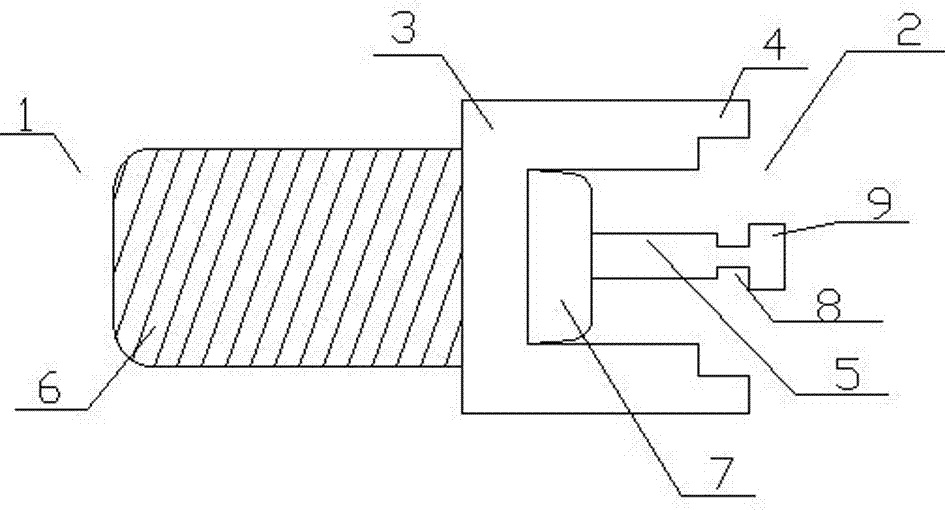

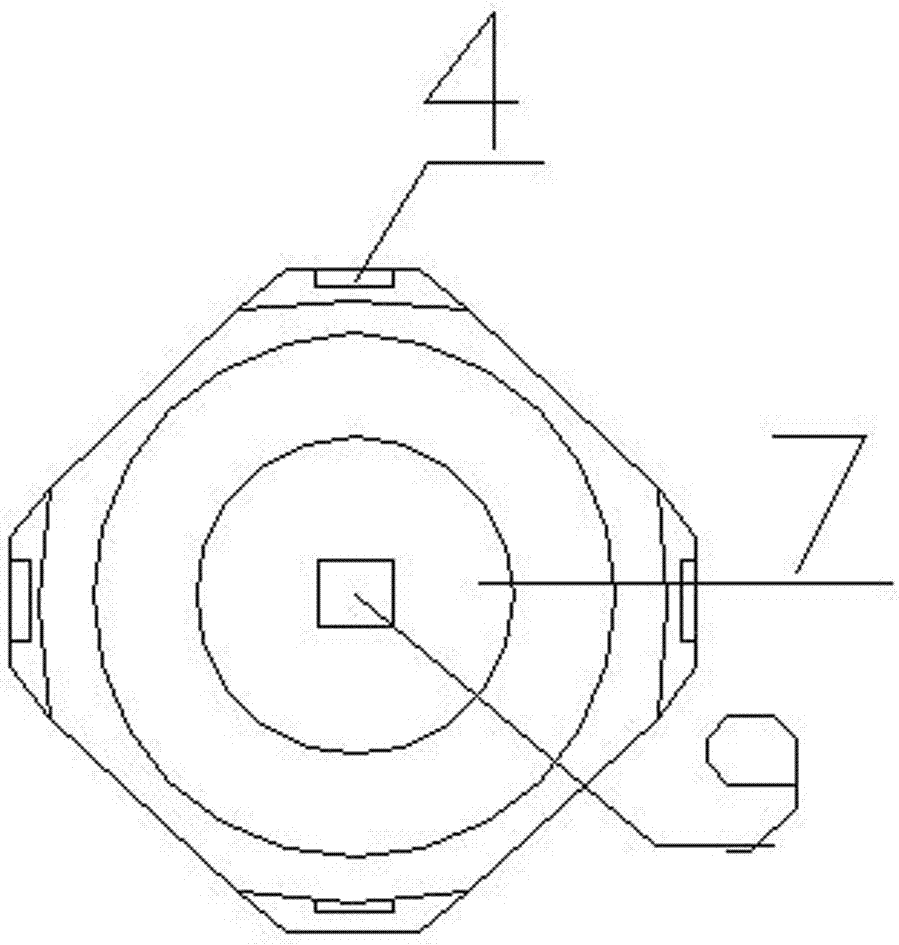

[0014] like figure 1 and figure 2 As shown, a connector base includes a cylindrical first joint 1 and a second joint 2, the first joint 1 and the second joint 2 are integrally cast; the first joint 1 includes a threaded end 6 and a joint End 7, threaded end 6 outer surface is provided with screw thread; Second joint 2 comprises base 3, side column 4 and inner column 5, and base 3 cross-section is square, and cross-sectional area is greater than the cross-sectional area of described first joint 1, Inlaid between the threaded end 6 and the joint end 7 of the first joint 1; the side columns 4 are arranged on the four corners of the base 3, extending along the direction of the joint end 7 of the first joint 1, and the extension ends of the side columns 4 are set There is a stepped structure; the inner column 5 is arranged on the axis of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com