A kind of ion exchange resin reproducibility testing method

A technology of ion exchange resin and testing method, which is applied in the field of ion exchange resin regeneration test, and can solve problems such as different calculation conditions and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

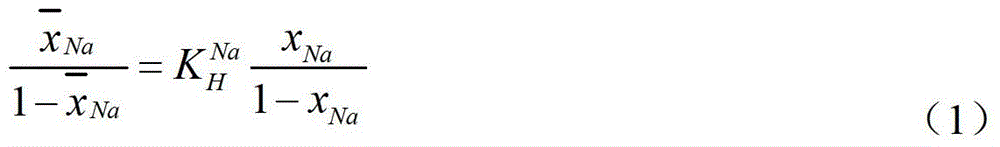

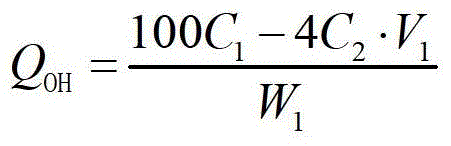

Method used

Image

Examples

Embodiment

[0115] This embodiment provides a method for testing the degree of regeneration of resin and a measurement test for the accuracy of the method.

[0116] Measurement of cation exchange resin regeneration error:

[0117] Take an appropriate amount of sodium-type cation exchange resin for fine treatment of mixed beds, and completely convert the sodium-type resin into hydrogen-type according to the "DL / T519-2004 Acceptance Standards for Ion-exchange Resins for Water Treatment in Thermal Power Plants". The two resins are mixed, and the hydrogen form rate in the mixed resin sample is measured by the above-mentioned method for measuring the degree of regeneration. The measurement process is as follows, and the measurement parameters and results are shown in Table 1 and Table 2.

[0118] 1. Determination of hydrogen exchange capacity:

[0119] (1) Take an appropriate amount of regenerated cation exchange resin, wash the resin with pure water, remove external moisture, weigh 2 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com