Water treatment ion exchange resin separation degree test system and test method

An ion exchange resin and resin separation technology, applied in the direction of material inspection products, etc., can solve the problems of no resin separation degree test system and method, low resin separation degree, etc., to optimize resin separation process parameters, improve regeneration level, and improve water yield The effect of water quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

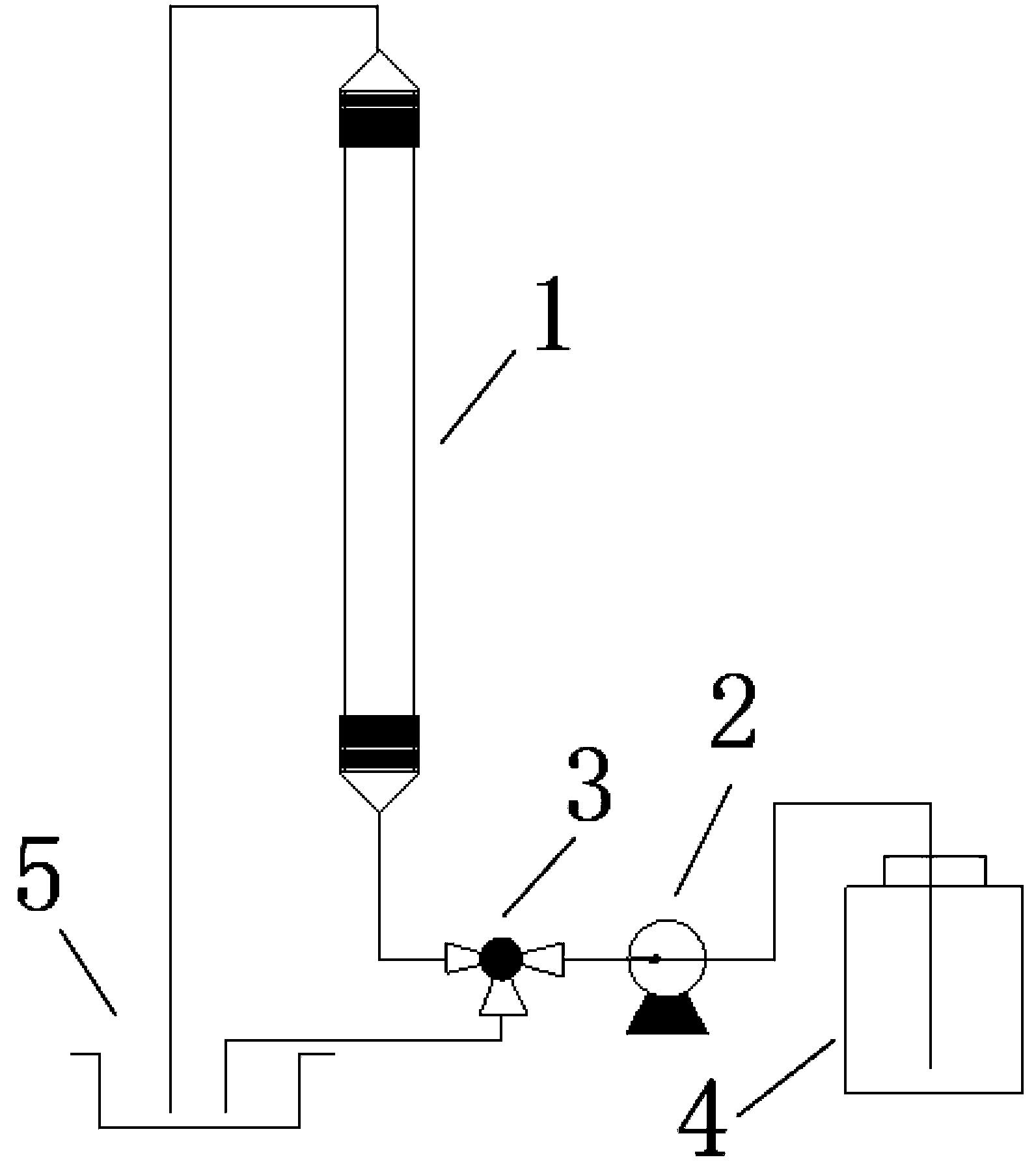

[0044] This embodiment provides a water treatment ion exchange resin separation degree test system, its structure is as follows figure 1 shown. The test system includes a resin separation column 1, a plunger metering pump 2, a three-way regulating valve 3, a water tank 4, and a discharge pool 5;

[0045] Wherein, the water tank 4 is connected to the first port of the three-way regulating valve 3 through a pipeline, and a plunger type metering pump 2 is arranged on the connecting pipeline;

[0046] The height of the resin separation column 1 is 1500 mm, the inner diameter is 20 mm, the joints at both ends are threaded joints, the water inlet and outlet structure is a double-layer porous plate sandwiching nylon mesh structure, and the resin separation column 1 is provided with a height line scale;

[0047] The bottom opening of the resin separation column 1 is connected with the second port of the three-way regulating valve 3, and the top opening of the resin separation column ...

Embodiment 2

[0050] This embodiment provides a method for testing the degree of separation of ion exchange resins for water treatment, which is a method for detecting the degree of separation using the system for measuring the degree of separation of ion exchange resins for water treatment provided in Example 1. The method includes the following steps:

[0051] (1) Pretreatment: Take 500mL resin sample and soak it with pure water or sodium hydroxide solution with a concentration of 2wt%-3wt% as the soaking solution for 10 minutes;

[0052] (2) Column loading: fill the resin separation column 1 with the resin sample to be analyzed, the filling height of the resin sample is 60-80cm, and the soaked resin sample and the soaking solution are loaded together during filling, and the resin surface is kept 10 cm above the surface. -20cm high soaking liquid;

[0053] (3) Backwashing: use pure water as the backwashing water, start the plunger metering pump 2, adjust the working frequency of the plung...

Embodiment 3

[0065] This embodiment provides a method for testing the separation degree of cation exchange resin. The method is to use the test device provided in Example 1 to perform the test on 3 groups of resins (the cation exchange resin is mixed with a certain amount of anion exchange resin, the resins whose serial numbers are 1, 2, and 3 in Table 1) according to the test method provided in Example 2. The degree of separation test, the amount of resin and the test results are shown in Table 1.

[0066] In this embodiment, the separation effects achieved by the resins with serial numbers 1, 2, and 3 are as follows: Figure 2-Figure 4 As shown in these figures, it can be seen that the resin layered interface is clear and horizontal, which shows that this embodiment has achieved a complete separation of the mixture of cation exchange resin mixed with anion exchange resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com