Self-adaptive power system and power supply method

A technology of self-adaptive power supply and power supply, which is applied in the direction of control/regulation system, adjustment of electrical variables, instruments, etc., can solve the problems of occupying a large volume, inconvenient to carry, complex structure, etc., and achieve the effect of improving portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

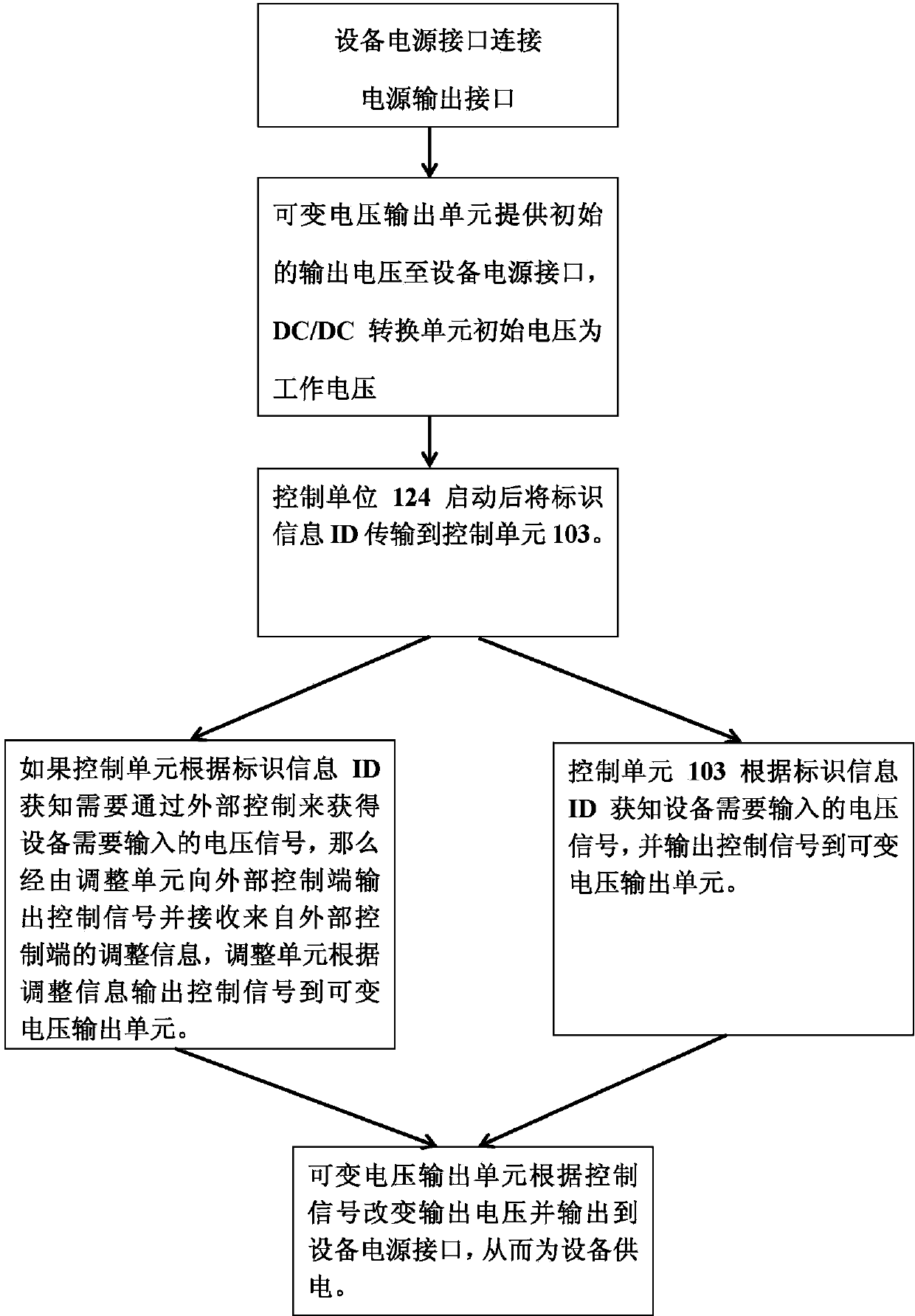

[0074] Since different electronic devices have different rated input voltages, in order to realize the adaptive change of the output voltage of the power system, it is necessary to provide identification information from the device side to the power side to indicate the required voltage signal level.

[0075] Fig. 1 shows an adaptive power supply system according to a first embodiment of the present invention. The adaptive power supply system 100 includes a power supply unit 101 , a device power interface 120 and a device 130 .

[0076] The device power interface 120 includes a power supply terminal VCC121 , a ground voltage terminal GND122 , data terminals D+ and D−, a voltage stabilizing module 123 and a control unit 124 . The power terminal VCC121 and the ground voltage terminal GND122 are connected to the power input terminal of the device 130 .

[0077] The input of the voltage stabilizing module 123 is connected to the power supply terminal VCC121 and the ground voltage...

Embodiment 2

[0090] Although the device power interface device of the connected device can provide the power supply unit with indication information, because the control unit in the device power interface only stores one ID information, it can only be used for a class of electronic devices that require the same input power. In order to be suitable for electronic equipment with different voltage requirements, in one case, it is necessary to change the ID information stored in the control unit in the equipment power interface to correspond to different voltage signals, so that the equipment power interface device can be commonly used for power supply of different electronic equipment, However, this requires additional modifying means to modify the ID information.

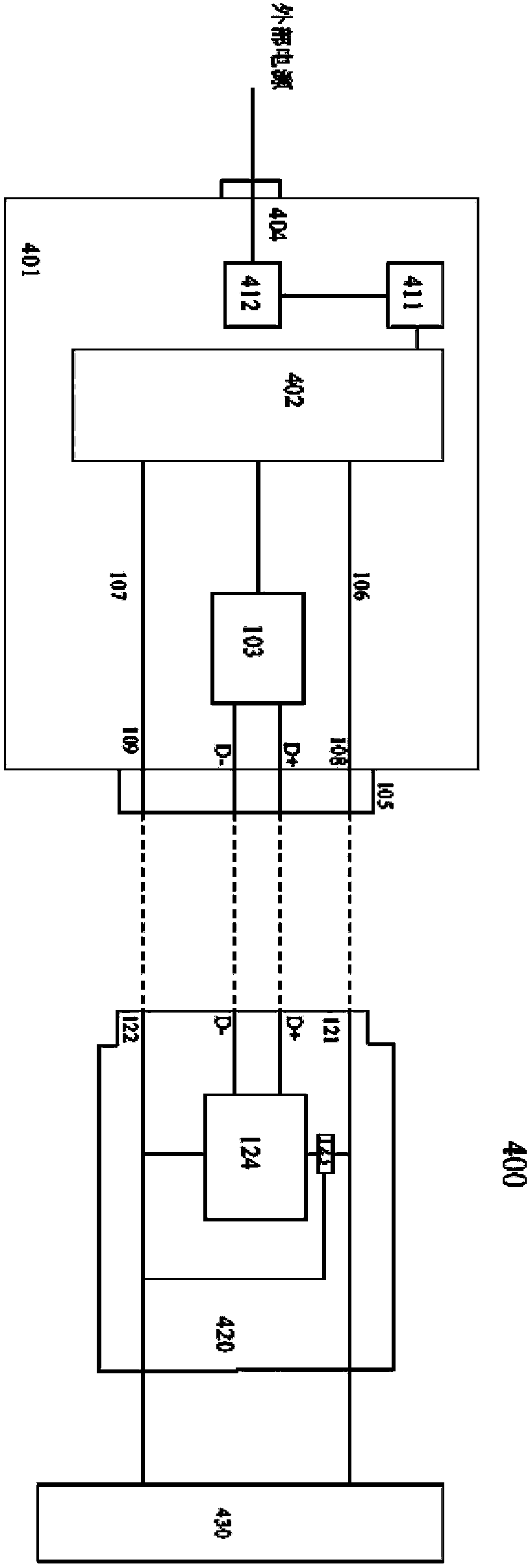

[0091] figure 2 An adaptive power supply system according to a second embodiment of the present invention is shown. The adaptive power system 200 includes a power supply unit 201 , a device power interface 220 and a device 230 ....

Embodiment 3

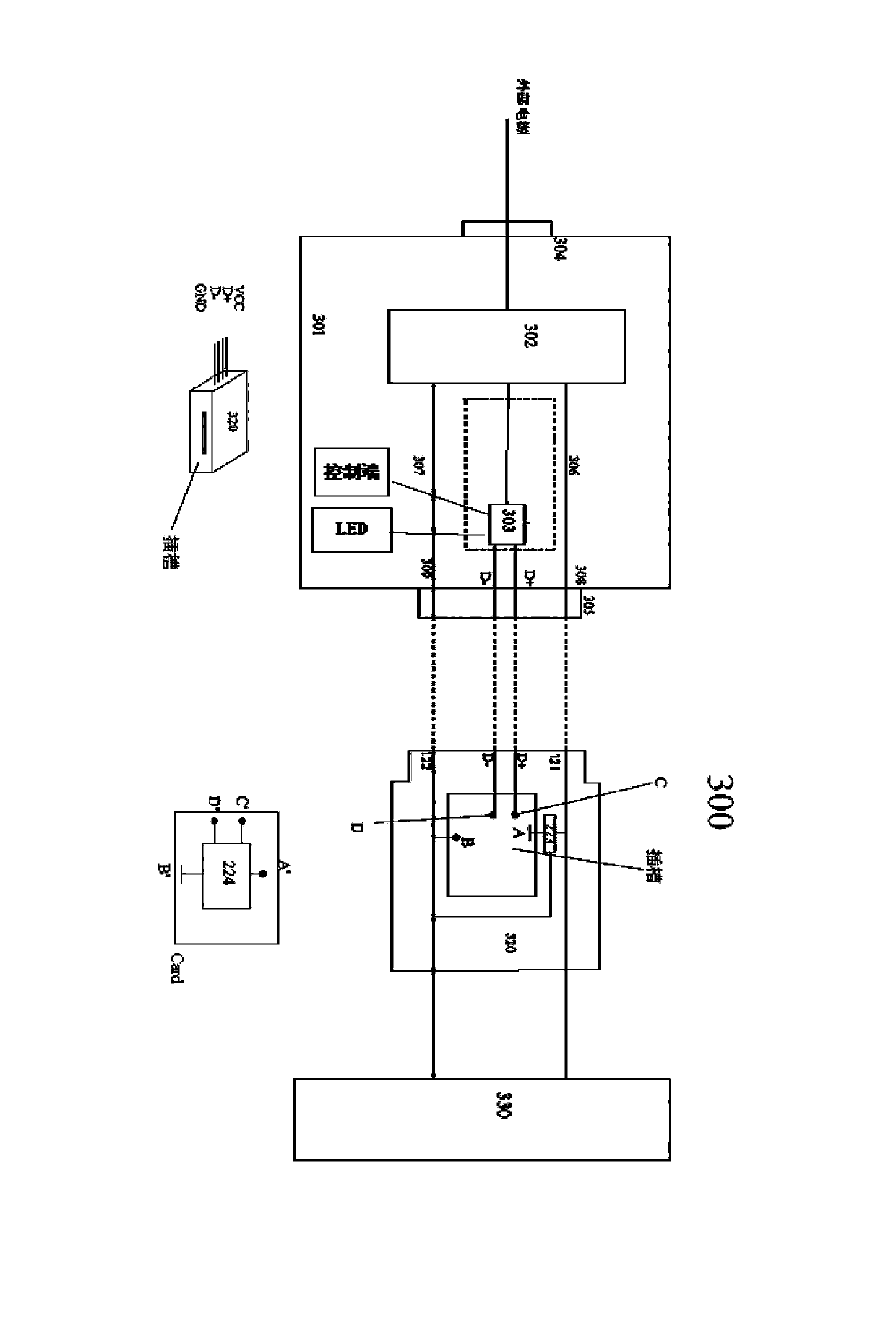

[0100] In the second embodiment, although the card-type device power interface can be used to supply power to different electronic devices by replacing circuit boards with different ID information, but due to the wide variety of electronic devices, at the same time It is not easy to know the power requirements of all known or unknown electronic devices. This may cause the user to carry a large number of circuit boards, or the power supply system cannot be used because there is no corresponding circuit board.

[0101] Figure 3A An adaptive power supply system according to a third embodiment of the present invention is shown. The adaptive power system 300 includes a power supply unit 301 , a device power interface 320 and a device 330 .

[0102] The connection relationship between the power supply unit 301, the device power interface 220 and the device 230 is the same as that of the first and second embodiments, and the internal structure of the device power interface 220 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com