Luggage with case, frame and lock

A luggage and shell technology, applied in the field of luggage, can solve the problems of increasing the cost and/or weight of luggage, and achieve the effects of increasing the size and filling volume, reducing the total weight, and having a neat appearance design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

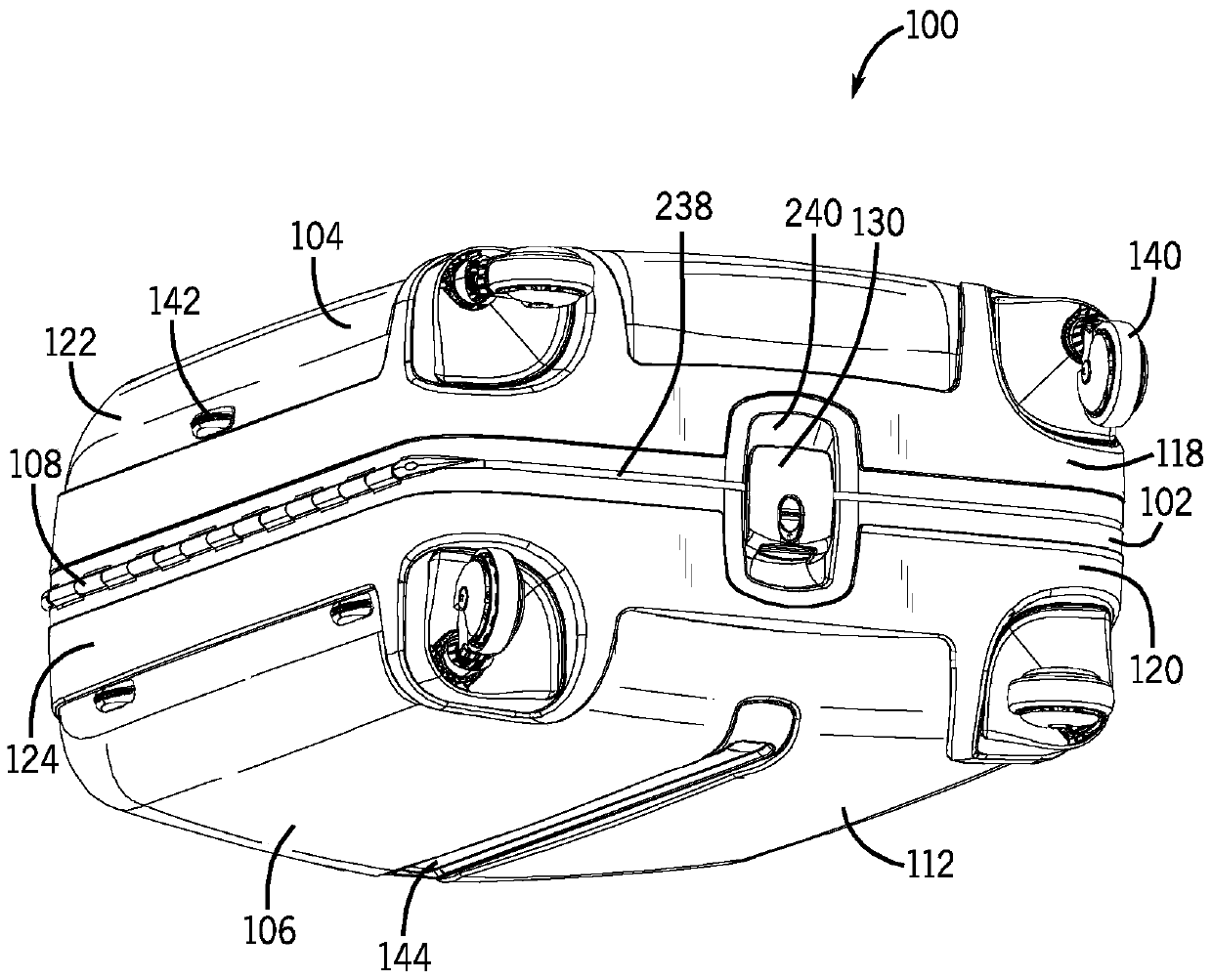

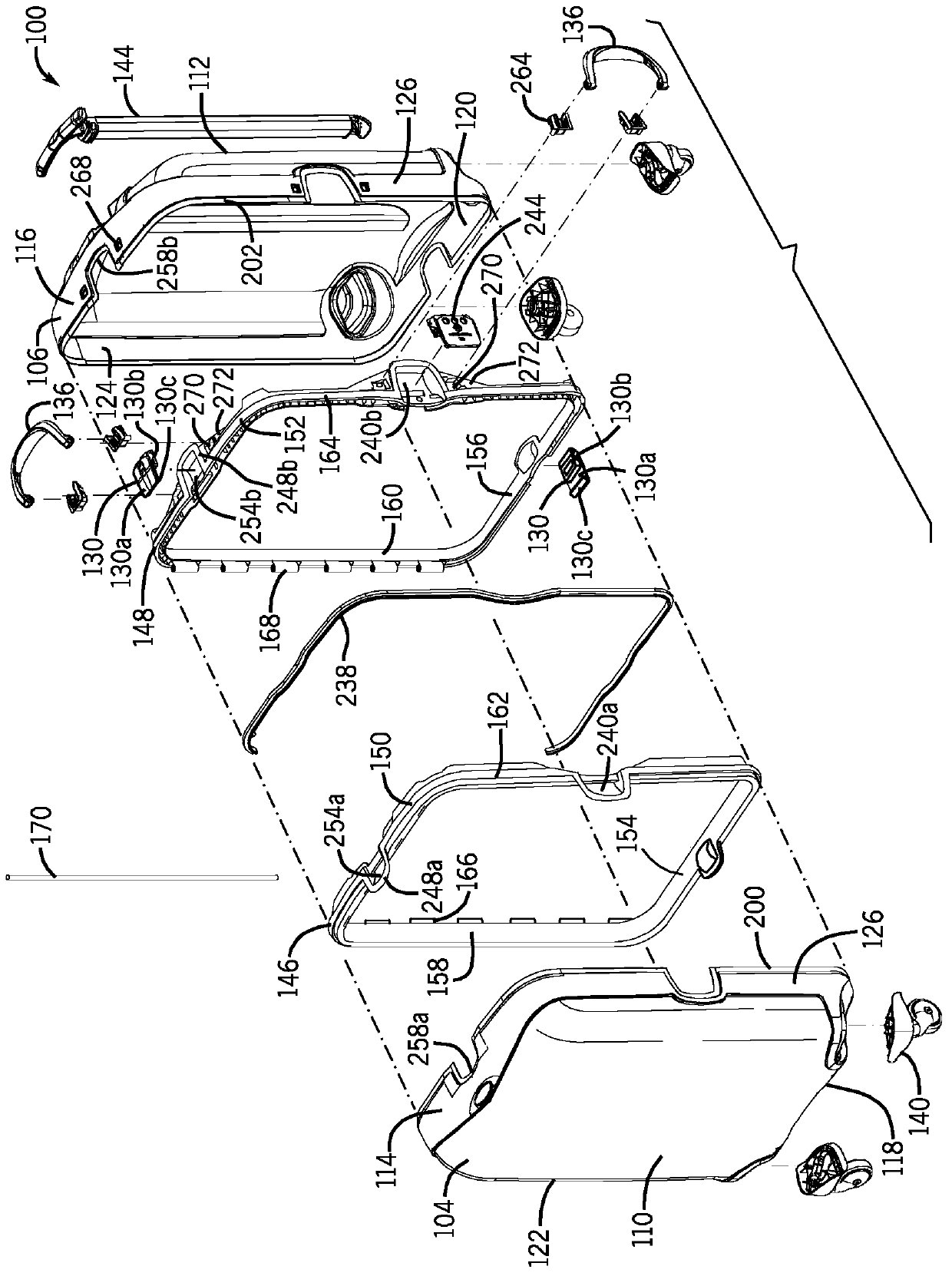

[0040] Described herein is a luggage case including a frame assembly. The luggage case may include a compartment enclosed by opposing shells, ie a front shell and a rear shell. Each shell may be a relatively rigid shell formed from any type of material used for hard-sided suitcases. The frame assembly may include peripheral frame members disposed along opposite edges / rims of the shell of the luggage case. The luggage case may further include peripheral components anchored to the frame assembly, such as locks and handles. The frame assembly and perimeter components may be configured to be substantially flush with an exterior surface of the luggage shell.

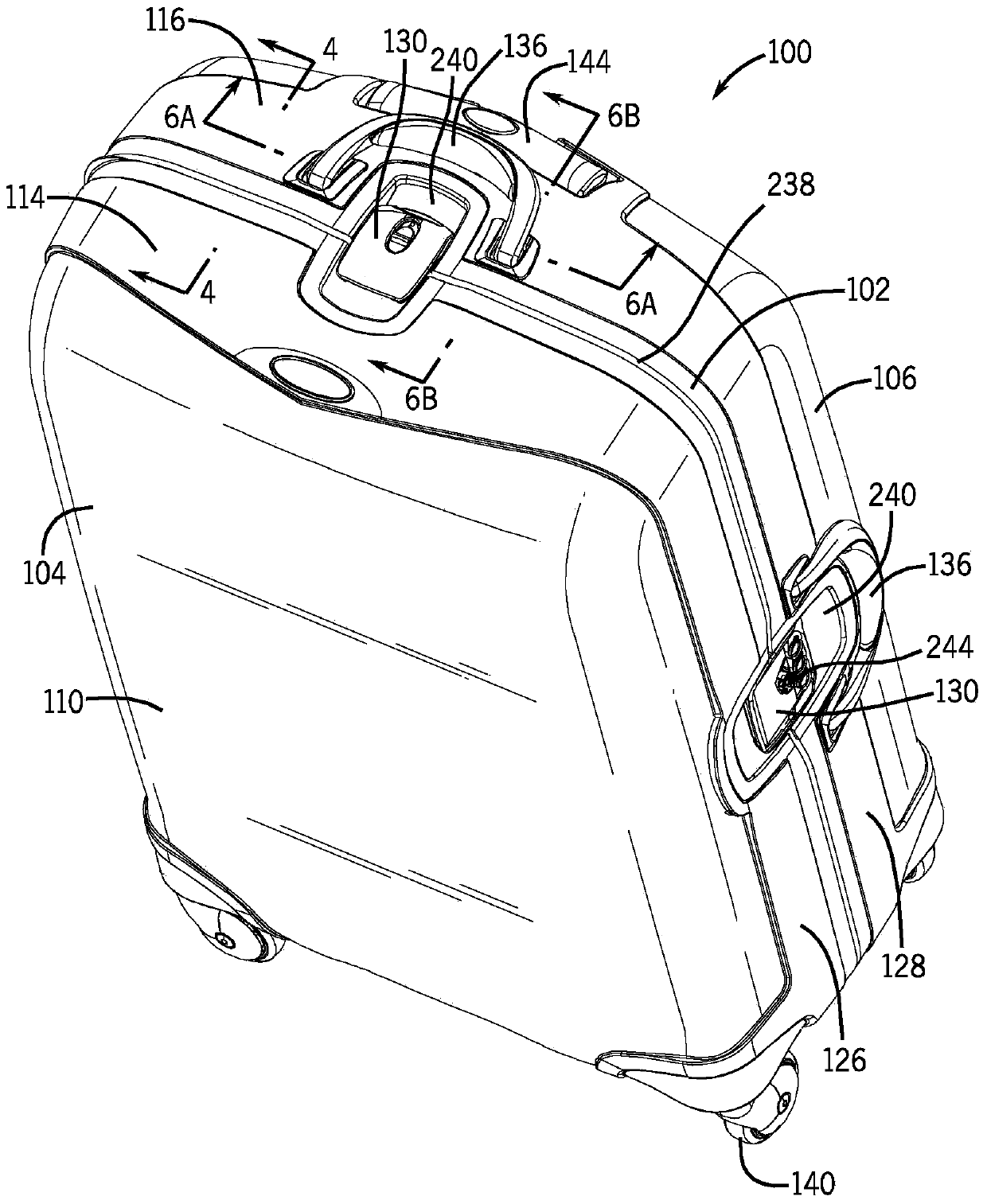

[0041] By way of example and not limitation, figure 1 , 2 and 3 show the luggage case 100 including the frame assembly 102 . The luggage case 100 may include a main compartment defined by two opposing shells, such as a front shell 104 and a rear shell 106, that are pivotally joined by a hinge member 108 to generally A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com