Large manual sand blasting system

A sandblasting and large-scale technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems that the dust mist in the sandblasting room cannot be fully recovered, the dust is automatically separated and recycled, and labor costs are increased. To achieve the effect of safe, practical, stable and reliable equipment, protection of health, and quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

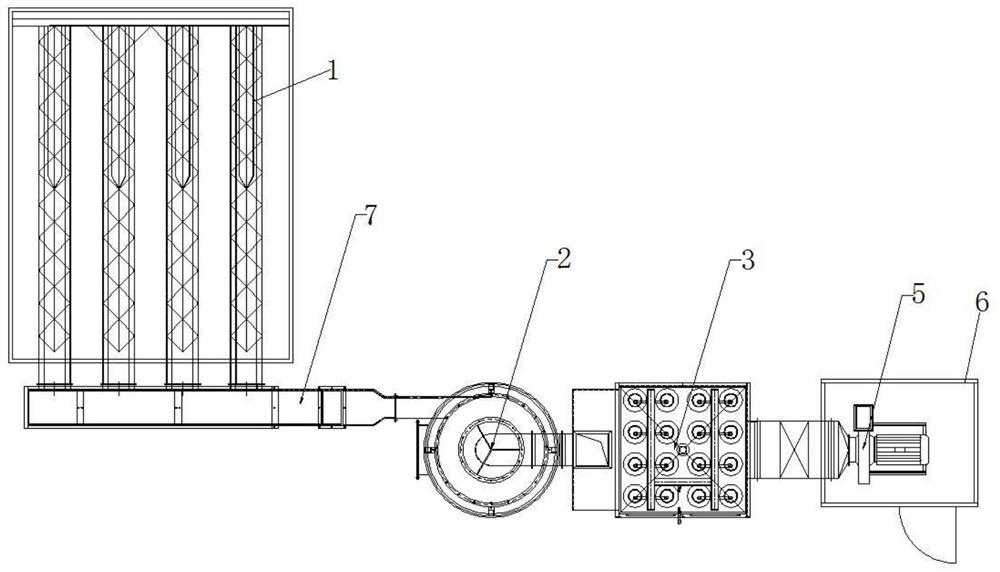

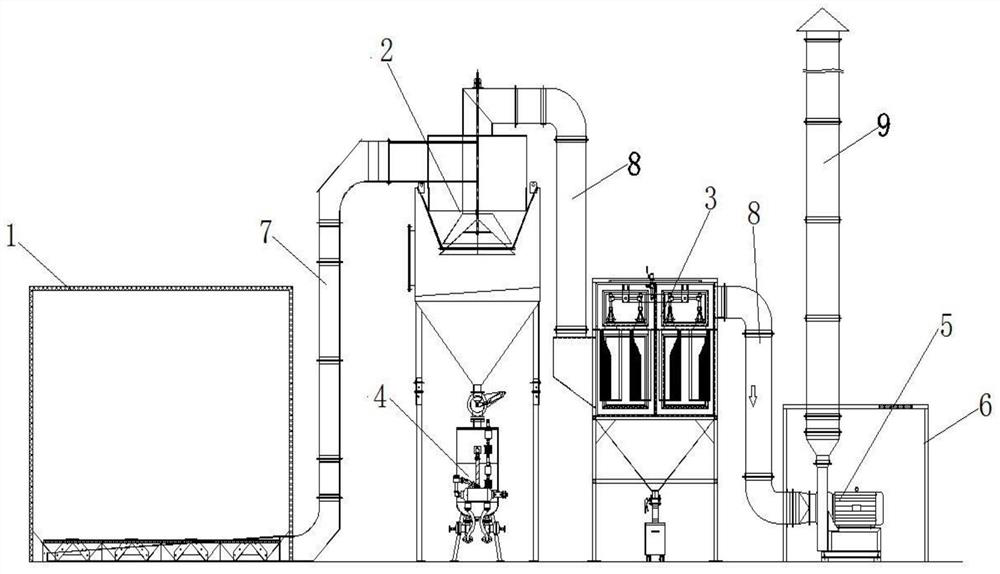

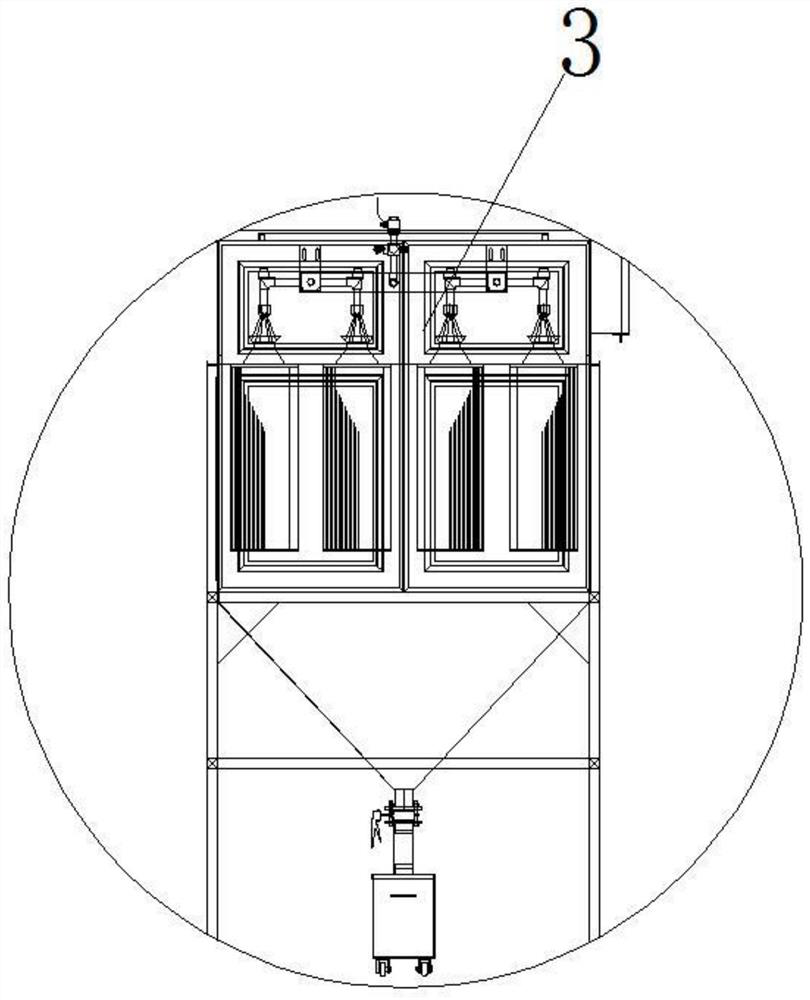

[0029] see Figure 1-4 , a large-scale manual sandblasting system, including a sandblasting system body, the sandblasting system body consists of a sandblasting studio 1, a cyclone separator 2, a secondary recovery device for filter elements 3, a sandblasting device 4, a high-pressure exhaust fan 5, and a high-pressure exhaust fan Machine soundproof room 6, main suction slot 7, suction slot 8, and main exhaust slot 9, a cyclone separator 2 is provided on one side of the sandblasting studio 1, and a sandblasting device 4 is provided at the lower end of the rotary separator 2, and the cyclone One side of the separator 2 is provided with a filter secondary recovery device 3, and one side of the filter secondary recovery device 3 is provided with a high-pressure exhaust fan 5, and a main suction slot 7 is provided between the sandblasting studio 1 and the cyclone separator 2. The structure of the suction groove 7 is a plurality of L-shaped structures, the cyclone separator 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com