Method for applying an aqueous treatment solution to the surface of a moving steel strip

A technology for treating solutions and steel strips, which can be used in pretreatment surfaces, devices for coating liquids on surfaces, spray devices with movable outlets, etc., which can solve problems such as aging of water-like treatment solutions and achieve the effect of avoiding waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

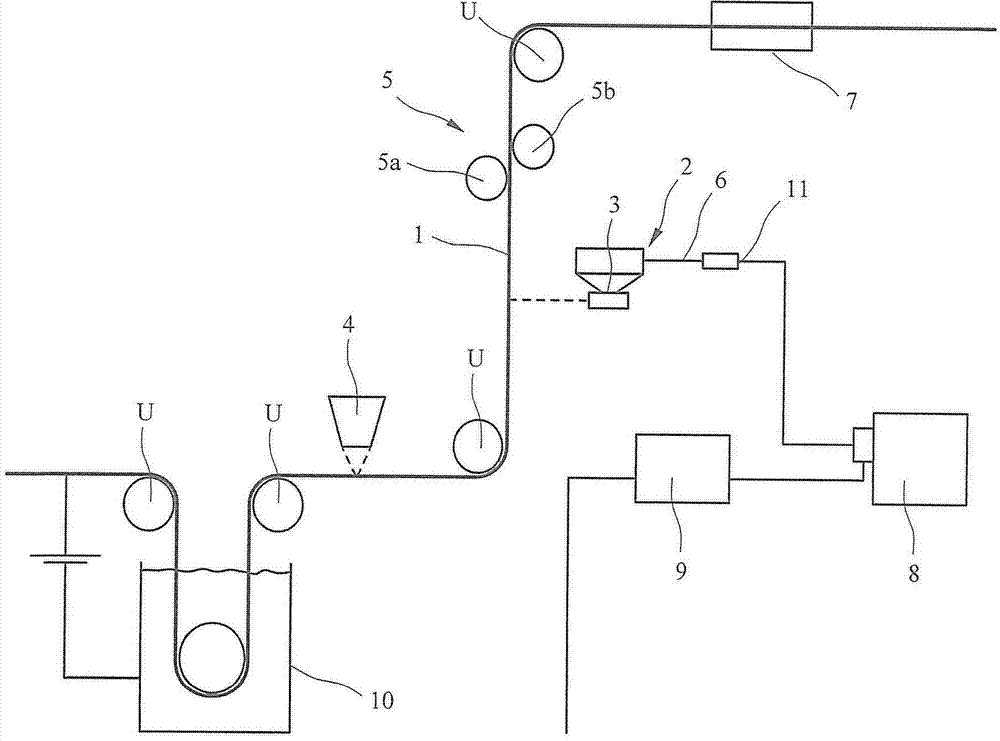

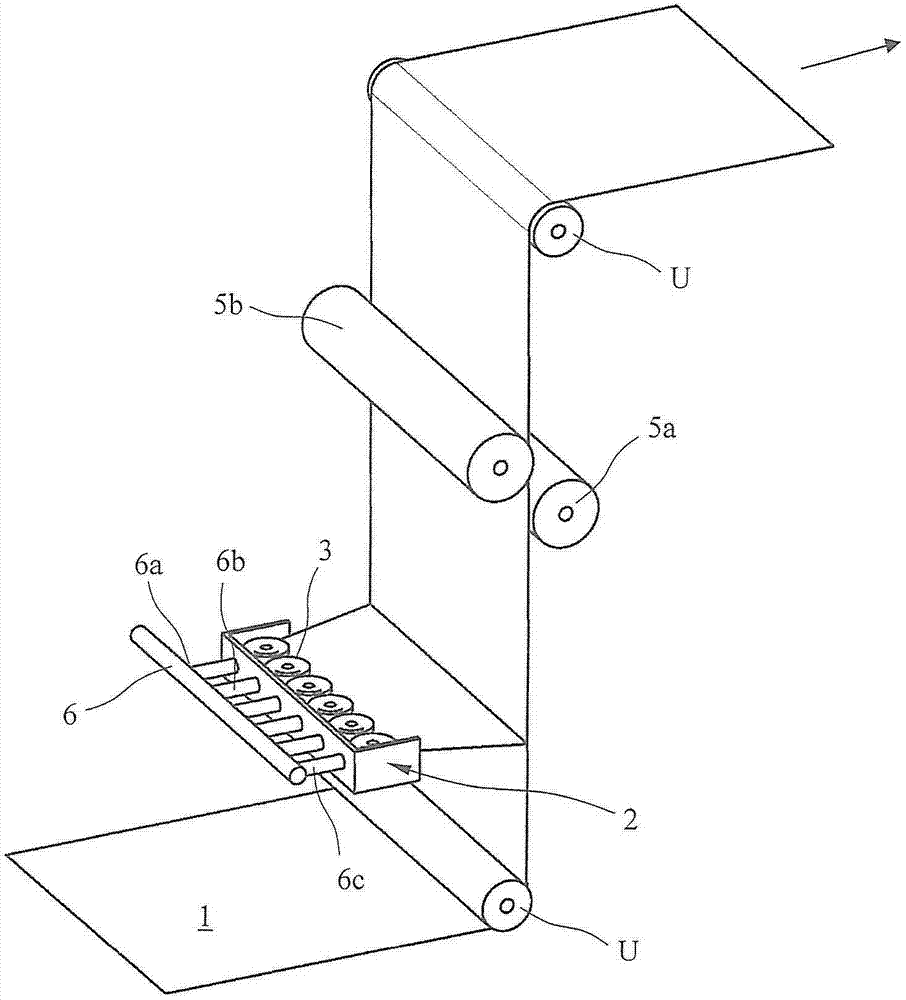

[0017] exist figure 1 A device for carrying out the method according to the invention for applying an aqueous treatment solution to the surface of a moving steel strip is schematically shown in . In this case, the steel strip 1 is guided by a plurality of deflecting rollers U, and the steel strip moves in the belt running direction at a preset belt speed v, at figure 1 The direction of travel of the belt is marked with an arrow in . Here, the belt speed is generally greater than 200 m / min and a maximum of 750 m / min. The steel strip 1 can be, for example, a metal-coated and cold-rolled steel strip, such as a white iron belt or a galvanized steel strip. However, it can also be an uncoated steel belt, such as a black iron belt.

[0018] With this transport device, not shown, the steel belt 1 is moved at a predetermined belt speed v in the direction of belt travel and is guided by deflection rollers U in the process. First, the steel belt 1 is guided through the first drying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com