Portable log splitter

A wood splitter, portable technology, applied in the field of wood splitting, can solve the problems of complex design, heavy carrying, inseparable, etc., to achieve the effect of increasing the use price, comfortable work, and eliminating transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

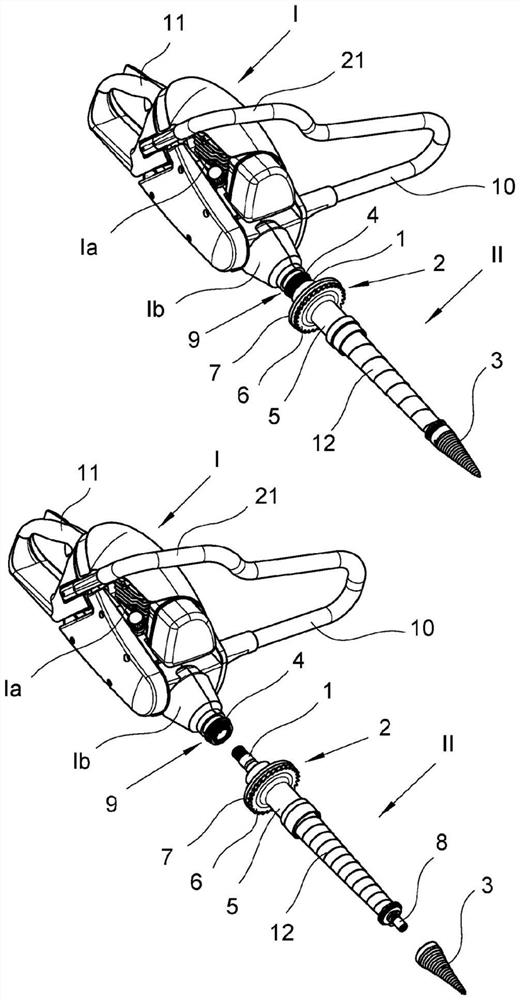

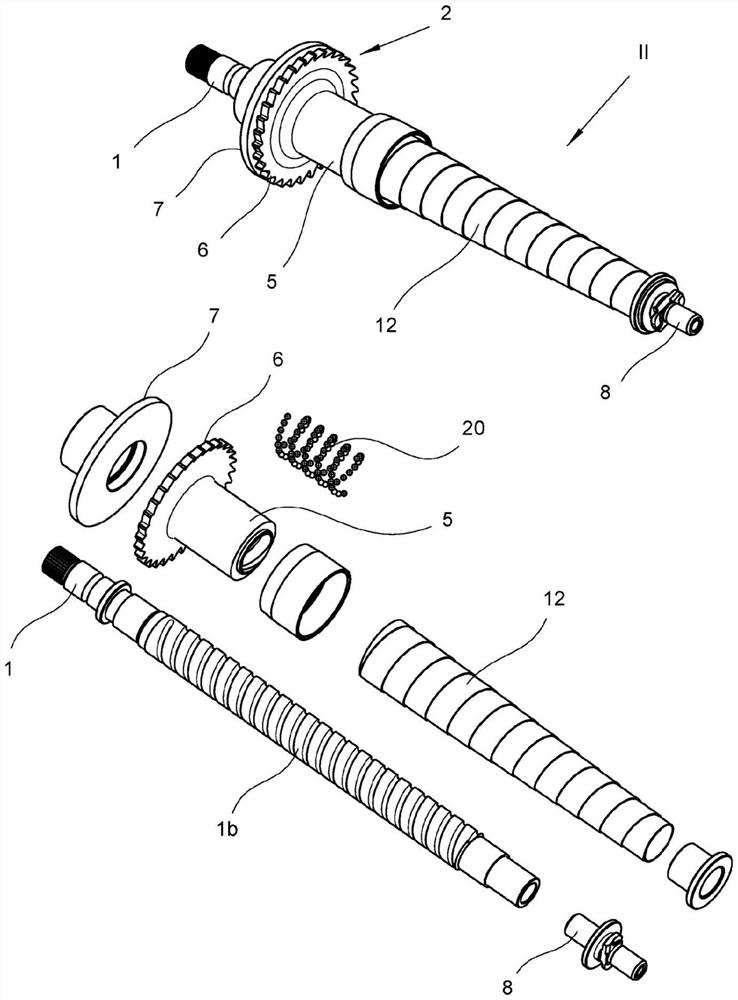

[0041] The portable log splitter in the exemplary embodiment of the present invention includes an assembly kit consisting of a power unit and a working tool. power unit I by the engine Ia and gearbox Ib Composition of which the gearbox is an integral part (see figure 1 ). homework tool II by drive shaft 1 composition, the drive shaft is equipped with an expansion mechanism 2 and split thread cone 3 (see figure 1 ). homework tool II and gearbox Ib output shaft 4 Component parts equipped with split thread cones for reproducible connections and disconnections. homework tool II drive shaft 1 is hollow and has threads on the outer circumference 1b , to be used to generate the expansion mechanism 2 (see image 3 details in ), this thread is threaded with the chainring 6 connected nut 5 , the nut can be driven due to the shaft 1 of the rotation while the drive shaft 1 The axial direction of the axis of rotation is shifted. on drive shaft 1 on, on its outp...

example 2

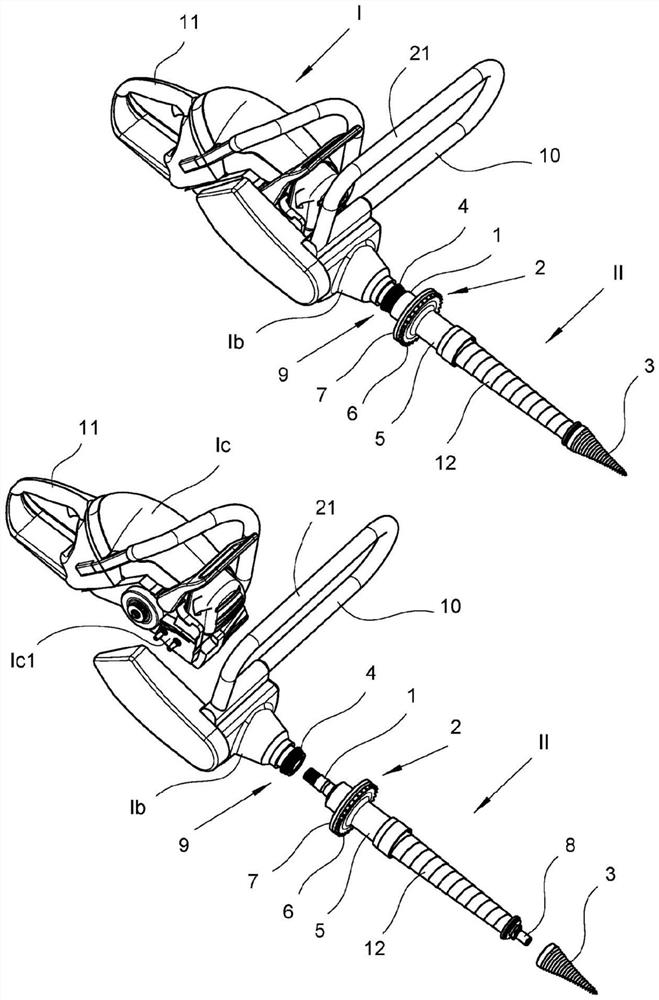

[0054] In other variants of the exemplary embodiment of the portable log splitter according to the present invention (see figure 2 ), power unit I chainsaw power unit IC and independent auxiliary gearbox Composition of Ib An assembly kit is formed which is detachably secured to the flange of the chainsaw cutting blade Ic1 superior. In this variant, the anti-torque bar (stop) 10 with separate auxiliary gearbox Ib securely attached, the anti-torque bar is also part of the first handle 21 .

[0055] The design of the other elements and components of the device is the same as in example 1.

example 3

[0057] In another arrangement of the portable log splitter according to the invention, the engine Ia The axis of the output shaft is parallel to the gearbox Ib output shaft 4 axis of rotation. In this case, the gearbox Ib is a multi-gearbox, The first gear and the last gear are formed by front gears, or the gearbox can be arranged as a planetary gearbox.

[0058] The design of the other elements and components of the device is the same as in example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com