Method for preparing special functional polycarboxylate water reducer for PHC pipe pile

A PHC pipe pile and functional technology, applied in the field of concrete admixtures, can solve the problems of increased energy consumption, large environmental pollution, rapid collapse, etc., and achieve the effects of green energy consumption, good repeatability, and easy construction.

Active Publication Date: 2015-01-21

JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Naphthalene-based superplasticizers have been used in the production of PHC pipe piles in my country. Naphthalene-based water-reducers have made great contributions to the pipe pile industry, but they have also exposed some insurmountable defects in the development of concrete technology: ①Prepared The slump loss of concrete is fast; ②The water-reducing rate is low, and the water-binder ratio is high, and autoclaving is required to achieve the strength requirement, which seriously increases energy consumption; ③The main raw material naphthalene will pollute the environment during the synthesis process, etc.

Some scholars also choose to use chemical grafting to introduce some defoaming components into the polycarboxylate superplasticizer molecules, so that the superplasticizer molecules have defoaming effects. This method better solves the problem of unstable mixtures. But most of them will affect the dispersion ability of polycarboxylate superplasticizer to a certain extent

Regarding the problem of improving the early strength of concrete, the main technical approaches at home and abroad are to change the composition or fineness of cement, and to add early-strength admixtures, e

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

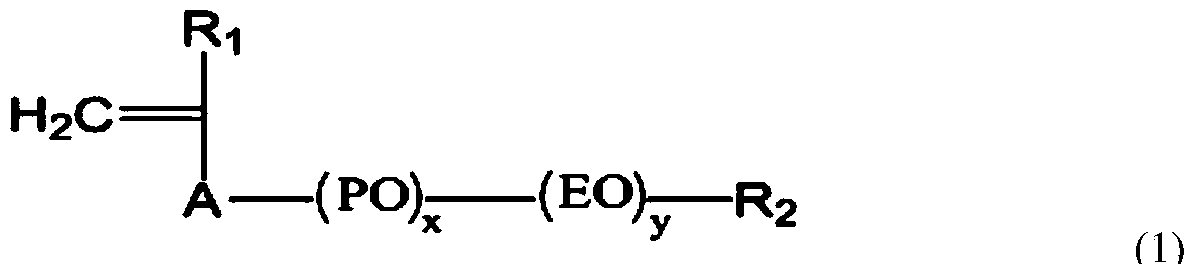

The invention discloses a method for preparing a special functional polycarboxylate water reducer for a PHC pipe pile. The water reducer is prepared by carrying out a free radical polymerization reaction among a macromonomer A, a small monomer B, a small monomer C and a small monomer D in a water-based medium under the action of a water-soluble redox system, wherein a molar ratio of the monomers A, B, C and D is 1:(3-9):(1-3):(1-3). The functional polycarboxylate water reducer disclosed by the invention has the advantages that (1) according to the reasonably designed polyether macromonomer, pore parameters and distribution uniformity inside hardened concrete can be obviously improved, and the compressive strength of the concrete is obviously enhanced; (2) early hydration of cement is obviously improved, and the early strength of the concrete is improved; (3) the water reducer has high dispersing capacity and dispersion retaining capacity under low mixing amount, the concrete strength is obviously enhanced, and the early strength effect is outstanding; and (4) fresh mixed concrete is good in working performance, low in apparent viscosity and convenient for construction.

Description

technical field [0001] The invention relates to a preparation method of a special functional polycarboxylate water reducer for PHC pipe piles. This functional polycarboxylate water reducer optimizes the internal pore parameters of hardened concrete on the premise of ensuring better dispersion and dispersion retention performance. and distribution uniformity, significantly enhance the strength of concrete, improve the early strength of concrete, and belong to the field of concrete admixtures. Background technique [0002] In the late 1980s, with the introduction of a full set of Japanese PHC pile production equipment and technology by the former Ministry of Communications Third Aviation Bureau Concrete Products Factory, my country has gradually promoted the production of pretensioned prestressed high-strength concrete pipe piles (PHC pipe piles). After more than 20 years of rapid development, there are currently more than 500 pipe pile manufacturers in my country, mainly dist...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F283/06C08F220/06C08F228/02C08F212/14C08F220/58C08F220/28C08F4/40C04B24/16C04B103/30

Inventor 李楠余韬

Owner JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com