Aluminum baking varnish hydroxy acrylic resin and preparation method and application thereof

A technology of baking varnish hydroxyacrylic acid and hydroxyacrylic acid, which is applied in the direction of coating, etc., can solve the problems of high environmental conditions, large investment in coating equipment, poor weather resistance, etc., and achieve reduced production costs, high adhesion, and superior fullness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

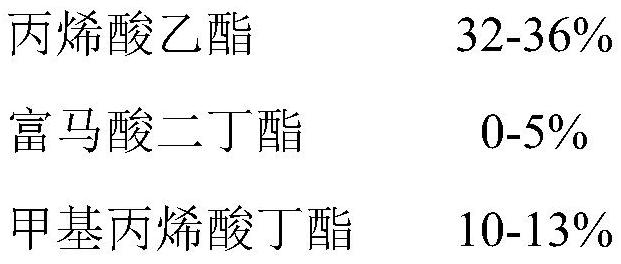

[0043] The aluminum baking varnish hydroxyacrylic resin described in the present embodiment 1 is composed of the following raw materials in terms of mass percentage:

[0044] Monomer 60%

[0045] Initiator 1.8%

[0046] Solvent 38.2%;

[0047] Described monomer, by mass percentage, is made up of following raw material:

[0048]

[0049] Described initiator, by mass percentage, is made up of following raw material:

[0050] tert-butyl peroxy-2-ethylhexanoate 80%

[0051] Azobisisobutyronitrile 20%;

[0052] Described solvent is ethylene glycol butyl ether.

[0053] The preparation method of the aluminum baking varnish hydroxyacrylic resin described in the present embodiment 1 consists of the following steps:

[0054] (1) Add 75wt% primer solvent ethylene glycol butyl ether and acrylamide to the four-necked reaction flask, and heat up to 125° C. under nitrogen atmosphere;

[0055](2) Add the remaining acrylic acid monomers to the monomer dropping tank: ethyl acrylate, ...

Embodiment 2

[0057] The aluminum baking varnish hydroxyacrylic resin described in the present embodiment 2 is composed of the following raw materials in terms of mass percentage:

[0058] Monomer 59%

[0059] Initiator 2%

[0060] Solvent 39%;

[0061] Described monomer, by mass percentage, is made up of following raw material:

[0062]

[0063] Described initiator, by mass percentage, is made up of following raw material:

[0064] tert-butyl peroxy-2-ethylhexanoate 80%

[0065] Azobisisobutyronitrile 20%;

[0066] Described solvent is ethylene glycol butyl ether.

[0067] The preparation method of the aluminum baking varnish hydroxyacrylic resin described in the present embodiment 2 is made up of the following steps:

[0068] (1) Add 70wt% primer solvent ethylene glycol butyl ether and fumaric acid in the four-necked reaction flask, and heat up to 125° C. for insulation under a nitrogen atmosphere;

[0069] (2) Add remaining acrylic acid monomers in the monomer dropping tank: et...

Embodiment 3

[0071] The aluminum baking varnish hydroxyacrylic resin described in the present embodiment 3 is composed of the following raw materials in terms of mass percentage:

[0072] Monomer 58.6%

[0073] Initiator 2.5%

[0074] Solvent 38.9%;

[0075] Described monomer, by mass percentage, is made up of following raw material:

[0076]

[0077] Described initiator, by mass percentage, is made up of following raw material:

[0078] tert-butyl peroxy-2-ethylhexanoate 90%

[0079] Azobisisobutyronitrile 10%;

[0080] Described solvent is ethylene glycol butyl ether.

[0081] The preparation method of the aluminum baking varnish hydroxyacrylic resin described in the present embodiment 3 consists of the following steps:

[0082] (1) Add 75wt% primer solvent ethylene glycol butyl ether and fumaric acid in the four-necked reaction flask, and heat up to 125° C. for insulation under a nitrogen atmosphere;

[0083] (2) Add remaining acrylic acid monomers in the monomer dropping tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com