force transmission device

A transmission device and tension sensor technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of loose connection and cooperation of sensors, inability to offset shackles, and inability to truly reflect the force of the wire rope of the protective net, etc., so as to improve the use of Longevity, evenly applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

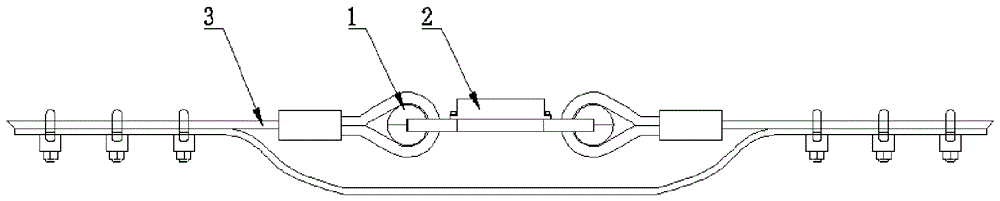

[0042] In order to make the purpose, structure and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

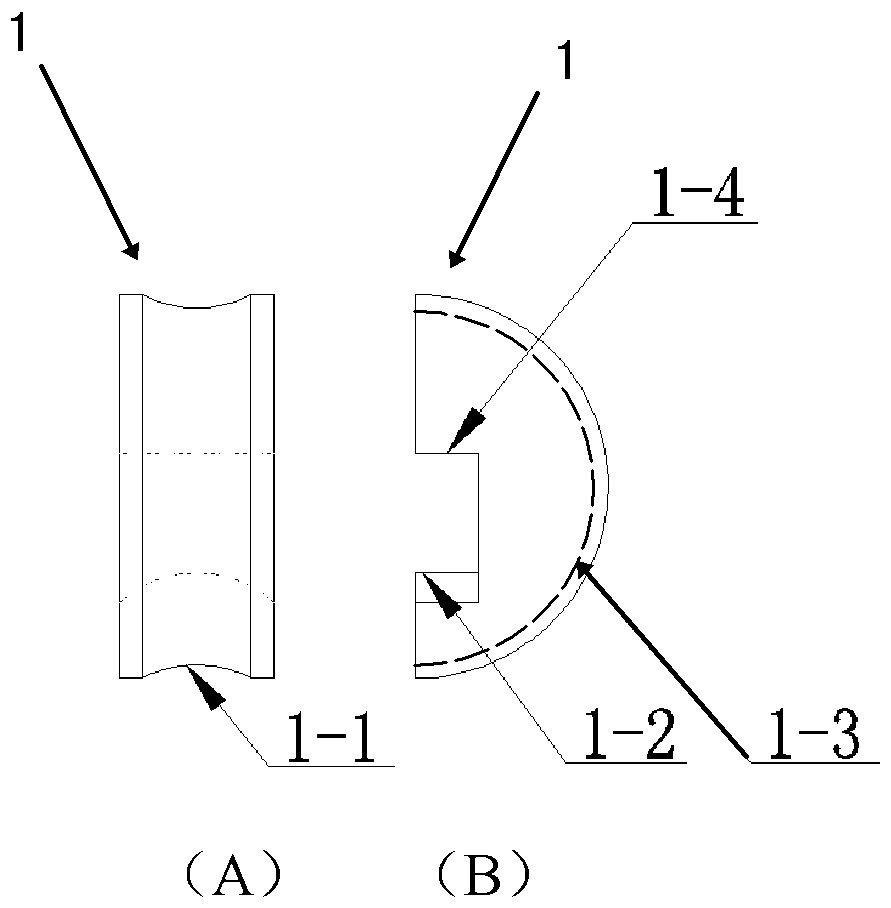

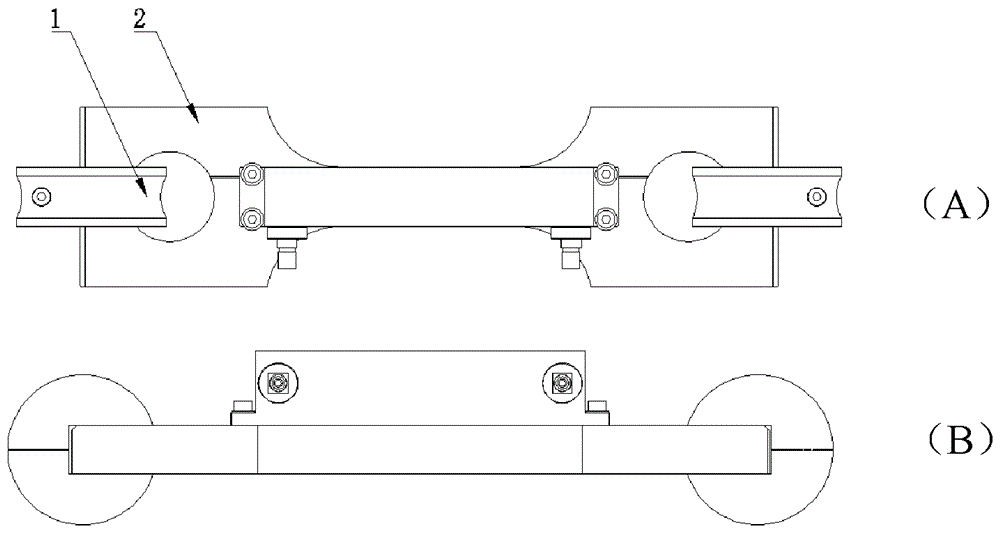

[0043] In the present invention, the force transmission means is composed of two semi-disc members (i.e., a first semi-disc member and a second semi-disc member) having a predetermined thickness and capable of being combined together to form a cylinder, which The structures of the two semi-disc-shaped components can be exactly the same, and can be combined and installed in the installation hole of the tension sensor. The installation hole of the tension sensor can be circular or square, but not limited thereto, and can also be in other shapes, as long as the force transmission device of the present invention can be installed on the tension sensor. That is, in the force transmission device of the present invention, the portion to be mounted in the mounting hole of the tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com