Display substrate, manufacturing method of display substrate and liquid crystal display panel

A display substrate and manufacturing method technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as afterimages in the display area, and achieve the effect of improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

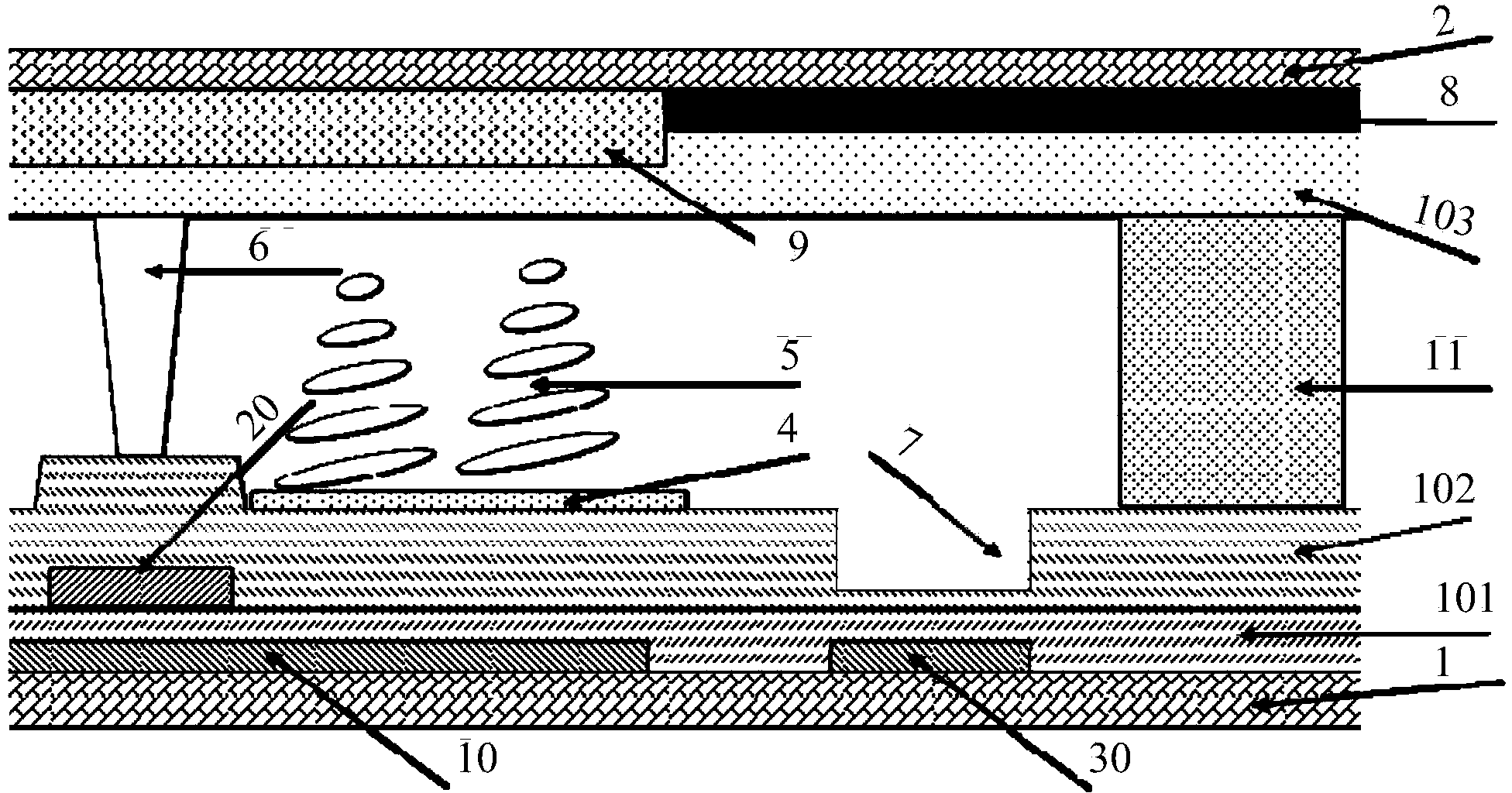

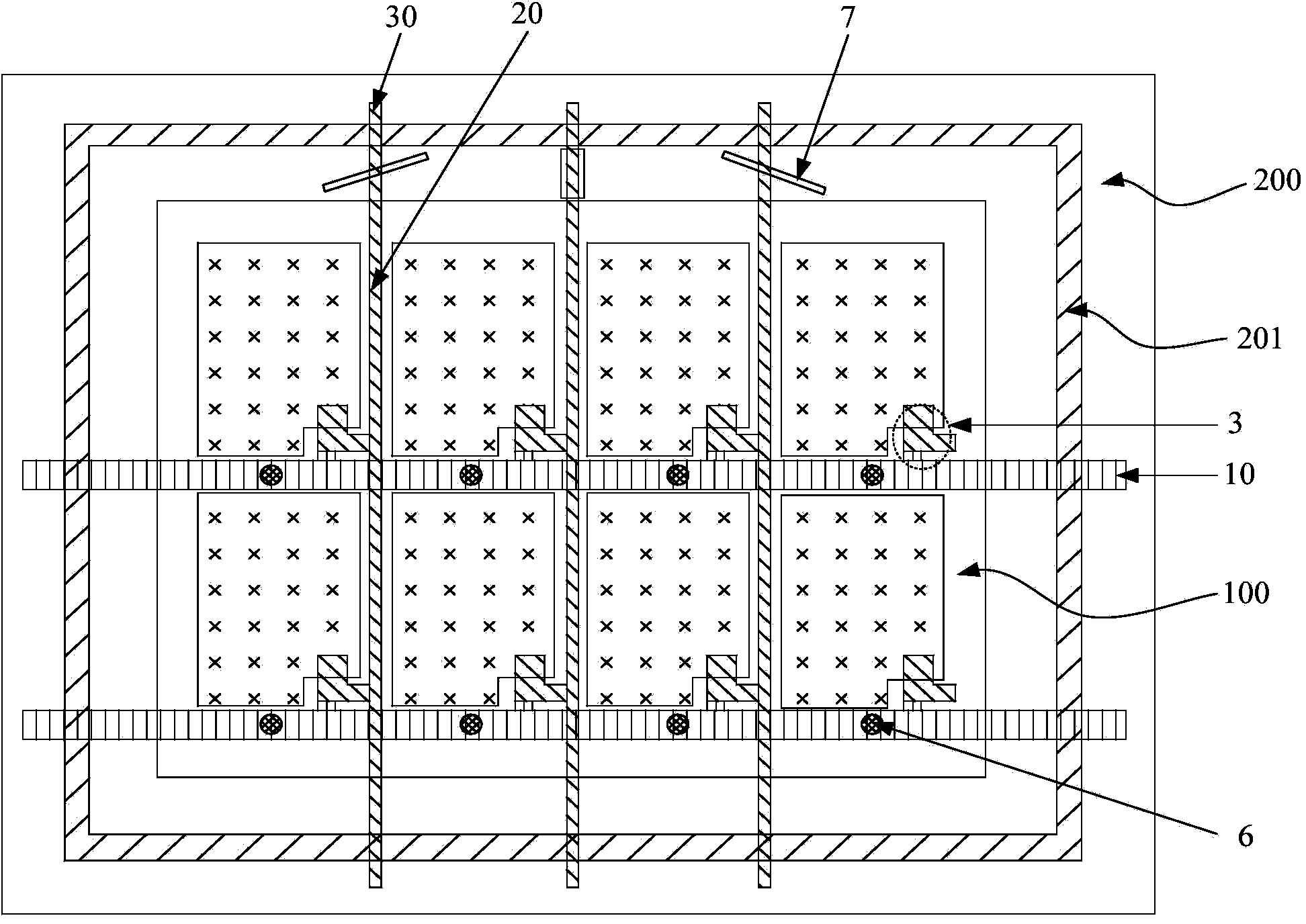

[0020] An embodiment of the present invention provides a display substrate for a liquid crystal panel. The display substrate is specifically an array substrate or a color filter substrate of a liquid crystal panel, including a display area and a non-display area located on the periphery of the display area, and an ion blocking structure is provided in the non-display area of the display substrate to block the non-display area. The charged ions diffuse to the display area.

[0021] The display substrate with the ion blocking structure can significantly improve the afterimage problem around the display area and improve the display quality of the liquid crystal display device.

[0022] In the manufacturing process of liquid crystal panels, charged ions are mainly introduced through two processes of sealant coating and liquid crystal dripping. Based on this, further, the ion blocking structure can be arranged between the sealing area of the non-display area and the display are...

Embodiment 2

[0042] Based on the same inventive concept, an embodiment of the present invention provides a method for manufacturing a display substrate, the display substrate is used for a liquid crystal panel, and includes a display area and a non-display area located on the periphery of the display area.

[0043] Described preparation method comprises:

[0044] An ion blocking structure is formed in the non-display area for blocking charged ions in the non-display area from diffusing to the display area.

[0045] By fabricating the ion blocking structure on the display substrate, the problem of image afterimages around the display area can be significantly improved, and the display quality of the liquid crystal display device can be improved.

[0046] Preferably, the ion blocking structure is located between the sealing area of the display substrate and the display area, and can effectively block charged ions introduced by coating the sealant and liquid crystal dripping from diffusing ...

Embodiment 3

[0090] An embodiment of the present invention also provides a liquid crystal panel, which includes the display substrate in the first embodiment.

[0091] By adopting the liquid crystal panel, the problem of image afterimages around the display area can be effectively solved, and the display quality of the liquid crystal display device can be improved.

[0092] In the technical solution of the present invention, by setting an ion blocking structure in the non-display area of the display substrate, it is used to prevent charged ions in the non-display area from diffusing to the display area, thereby effectively solving the problem of afterimages around the display area and improving the performance of liquid crystal display devices. display quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com